Automobile exhaust afterheat recycling system

A technology for automobile exhaust and waste heat recovery, applied in vehicle components, air treatment equipment, heating/cooling equipment, etc., can solve problems such as energy waste, endless emergence, environmental pollution, etc., to avoid excessive temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

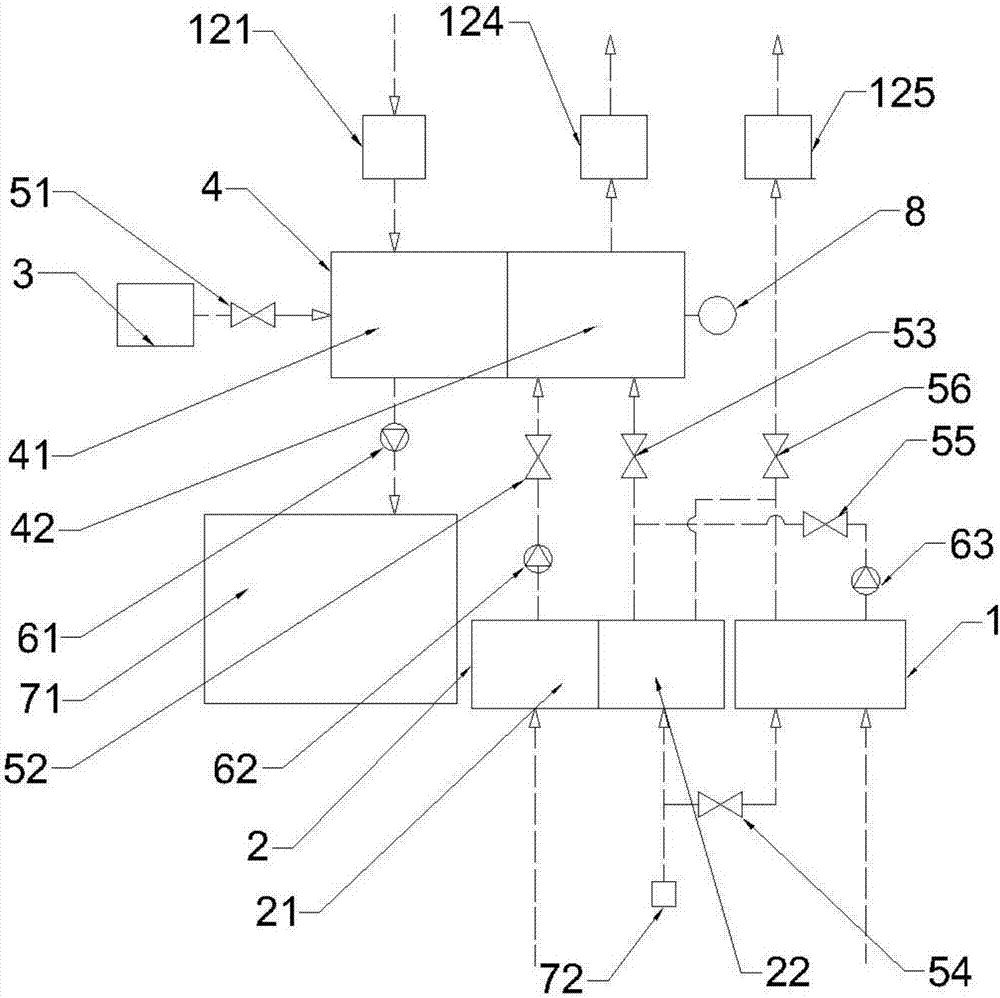

[0048] Example 1: Summer

[0049] Such as Figure 3-4 As shown, valve IV54 and valve VI56 are opened, valve III53 and valve V55 are closed, in the figure, the unconnected line is omitted, and a part of automobile exhaust gas 72 passes through the exhaust side IV22 of heat pipe heat exchanger 2 to transfer a part of heat to the air inlet III The incoming air is then discharged to the atmosphere through valve VI56. The other part of automobile exhaust enters the phase-change heat exchanger 1 through the intake pipe of the air inlet V and the valve IV54, stores the heat in the phase-change heat exchanger 1, and then discharges through the outlet pipe connected to the air outlet V and the valve VI56. In the atmosphere, due to the high temperature in summer, the exhaust gas generates a lot of heat. This part of the heat is stored as a backup. When the exhaust gas is insufficient, this part of the heat can be used. Specifically, open the valve Ⅲ53 and the valve Ⅴ55, in the induced ...

Embodiment 2

[0052] Example 2: Winter

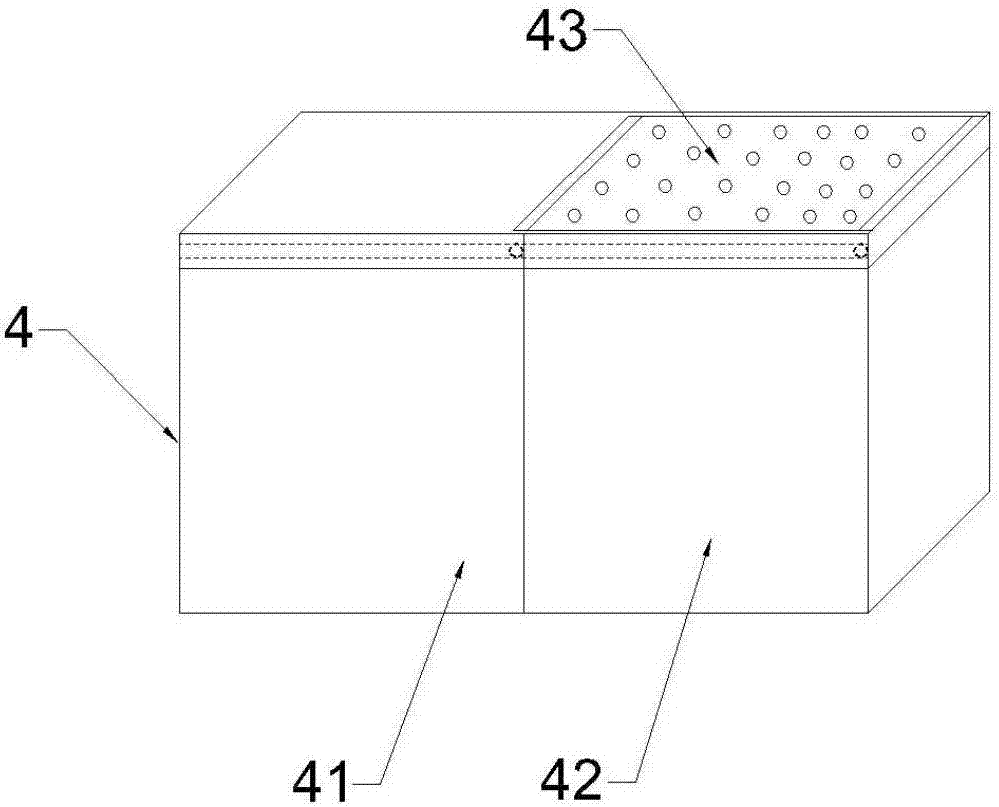

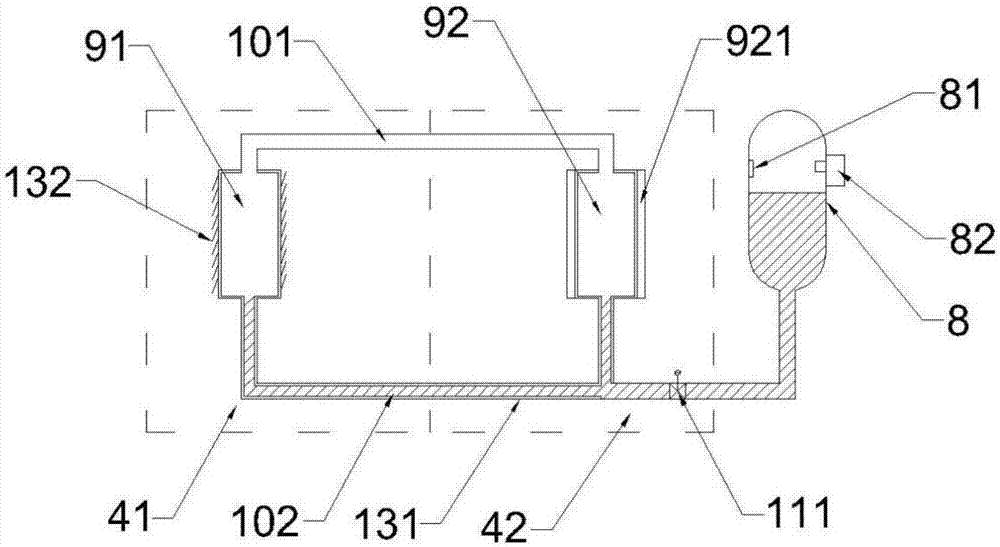

[0053] Such as Figure 5-6 As shown, open valve III53 and valve V55, close valve II52, valve IV54 and valve VI56. In the figure, the unconnected line is omitted, and the exhaust gas 72 of the automobile passes through the exhaust side IV22 of the heat pipe heat exchanger 2, and then enters the heat pipe evaporative cooler 4 exhaust side II42, in addition, under the action of the induced draft fan II62, the air passing through the phase change heat exchanger 1 is heated, and also enters the exhaust gas side II42 of the heat pipe evaporative cooler 4, and the two high-temperature air is mixed with the exhaust gas of the vehicle , heating the winter evaporating section 94, the heat of the winter evaporating section 94 is transferred to the winter condensing section 93 through the steam pipeline 101, thereby increasing the temperature of the air side I41; opening the valve I51, and the water spray tray 43 slides to the heat pipe evaporative cooler Above...

Embodiment 3

[0055] Example 3: Summer and Winter

[0056] Different from Embodiment 1 and Embodiment 2, the air side I41 of the heat pipe evaporative cooler 4 includes a summer evaporation section 91 and a winter condensation section 93, and the tail gas side II42 includes a summer condensation section 92 and a winter evaporation section 94. The liquid storage tank 8 is connected with the liquid pipeline 102 through the catheter, and the catheter is provided with an electric regulating valve 111, and the system can be used in both summer and winter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com