Spraying rapid-solidification waterproof coating and preparation method thereof

A technology of waterproof coating and production method, which is applied in the direction of asphalt coating, chloroprene homopolymer coating, coating, etc., can solve the problems of poor low temperature resistance and low self-healing ability, and achieve excellent chemical resistance, anti-corrosion Strong puncture performance and the effect of solving leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] A spraying quick-setting waterproof coating is composed of asphalt glue emulsion and curing agent, wherein,

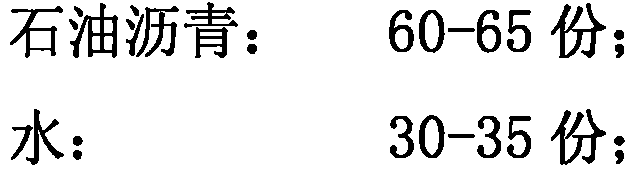

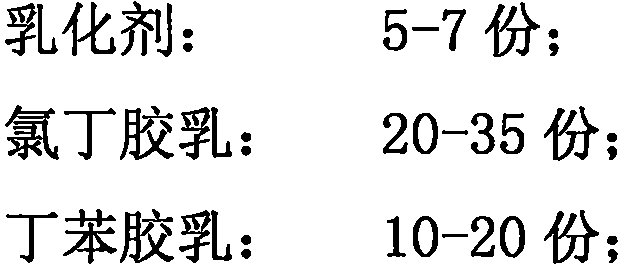

[0083] Asphalt latex consists of the following components by weight:

[0084]

[0085] Curing agent is made up of following components by weight:

[0086] Anhydrous calcium chloride: 10 parts;

[0087] Water: 90 parts.

[0088] The production method of above-mentioned spraying quick-setting waterproof paint, comprises the following steps:

[0089] 1) taking the raw materials of the above weight parts;

[0090] 2) Preparation of asphalt rubber emulsion:

[0091] A. Heat the petroleum asphalt to 120 degrees;

[0092] B. Mix the emulsifier and water, stir and heat to 60 degrees;

[0093] C. Open the colloid mill to emulsify the petroleum asphalt;

[0094] D. Turn on the delivery pump, send the emulsified asphalt into the modified mixing tank, add neoprene latex and styrene-butadiene latex to mix, and stir for 8 minutes;

[0095] E. Measuring packaging;

...

Embodiment 2

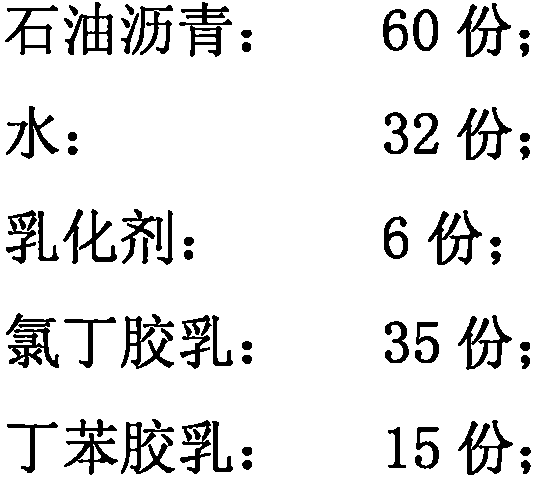

[0099] A spraying quick-setting waterproof coating is composed of asphalt glue emulsion and curing agent, wherein,

[0100] Asphalt latex consists of the following components by weight:

[0101]

[0102] Curing agent is made up of following components by weight:

[0103] Anhydrous calcium chloride: 12 parts;

[0104] Water: 88 parts.

[0105] The production method of above-mentioned spraying quick-setting waterproof paint, comprises the following steps:

[0106] 1) taking the raw materials of the above weight parts;

[0107] 2) Preparation of asphalt rubber emulsion:

[0108] A. Heat the asphalt to 130 degrees;

[0109] B. Mix the emulsifier and water, stir and heat to 65 degrees;

[0110] C. Open the colloid mill to emulsify the petroleum asphalt;

[0111] D. Turn on the delivery pump, send the emulsified asphalt into the modified mixing tank, add neoprene latex and styrene-butadiene latex to mix, and stir for 10 minutes;

[0112] E. Measuring packaging;

[0113] ...

Embodiment 3

[0116] A spraying quick-setting waterproof coating is composed of asphalt glue emulsion and curing agent, wherein,

[0117] Asphalt latex consists of the following components by weight:

[0118]

[0119] Curing agent is made up of following components by weight:

[0120] Anhydrous calcium chloride: 15 parts;

[0121] Water: 85 parts.

[0122] The production method of above-mentioned spraying quick-setting waterproof paint, comprises the following steps:

[0123] 1) taking the raw materials of the above weight parts;

[0124] 2) Preparation of asphalt rubber emulsion:

[0125] A. Heat the petroleum asphalt to 140 degrees;

[0126] B. Mix the emulsifier and water, stir and heat to 70 degrees;

[0127] C. Open the colloid mill to emulsify the petroleum asphalt;

[0128] D. Turn on the delivery pump, send the emulsified asphalt into the modified mixing tank, add neoprene latex and styrene-butadiene latex to mix, and stir for 12 minutes;

[0129] E. Measuring packaging; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com