Aroma sustained-release agent for cigarettes, and preparation method and application thereof

A slow-release agent and aroma technology, applied in the field of aroma slow-release agents, can solve the problems of inability to effectively utilize water-soluble tobacco flavors and fragrances, unsatisfactory stability of the tobacco aroma slow-release agent, and uneven release of aroma substances, and the like, To achieve the effect of no bad breath, low equipment requirements, and uniform release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

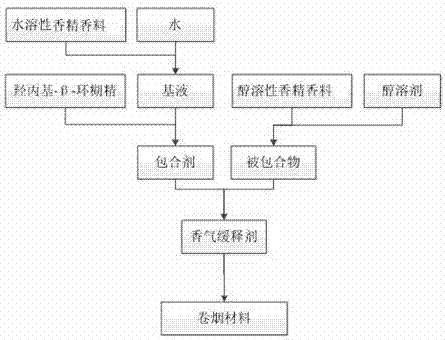

[0036] Such as figure 1 Shown, the preparation method of the aroma slow-release agent for tobacco of the present embodiment is as follows:

[0037] Add 1g of ethyl maltol, 5g of chamomile extract and 50g of water into a beaker, and stir for 6 minutes under the conditions of rotating speed of 150rpm and temperature of 25°C to obtain a light yellow clear solution, which is the base solution .

[0038] Fully dissolve 22.4g of hydroxypropyl-β-cyclodextrin in the base liquid obtained in the above steps, and stir for 20min under the conditions of a rotation speed of 280rpm and a temperature of 25°C to obtain 78.4g of a light yellow clear solution. That is the inclusion agent.

[0039] Add 5g of jasmine essential oil and a mixture of 2.4g of ethanol and propylene glycol in a beaker, wherein the ratio of ethanol to propylene glycol is 3:1, and stir for 5min under the conditions of a rotation speed of 200rpm and a temperature of 25°C, and the resulting solution is clathrate .

[00...

Embodiment 2

[0043] Such as figure 1 Shown, the preparation method of the aroma slow-release agent for tobacco of the present embodiment is as follows:

[0044] Add 1.5g of licorice extract and 60g of water into a beaker, and stir for 8min under the conditions of a rotating speed of 200rpm and a temperature of 21°C to obtain a light brown clear solution, which is the base solution.

[0045] Fully dissolve 50g of hydroxypropyl-β-cyclodextrin in the base liquid obtained in the above steps, and stir for 25 minutes under the conditions of a rotation speed of 250rpm and a temperature of 21°C to obtain 111.5g of a light brown clear solution, which is For inclusion agent.

[0046] Add 8g of peppermint essential oil, 5g of menthyl lactate, 0.5g of cooling agent WS23 and 5g of ethanol into a beaker, and stir for 10min under the conditions of a rotation speed of 220rpm and a temperature of 21°C, and the resulting solution is clathrate.

[0047] Put the clathrate agent into a beaker, and under the co...

Embodiment 3

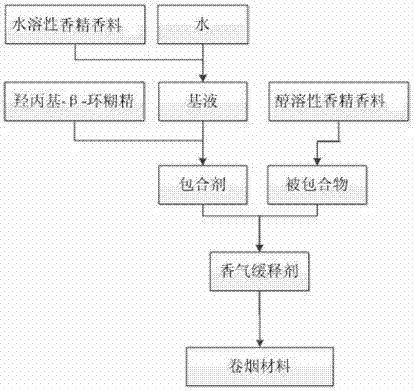

[0050] Such as figure 2 Shown, the preparation method of the aroma slow-release agent for tobacco of the present embodiment is as follows:

[0051] Add 2g of tea extract, 1g of mannitol and 50g of water into a beaker, and stir for 8min at a speed of 170rpm and a temperature of 23°C to obtain a light brown clear solution, which is the base solution.

[0052] Fully dissolve 5g of hydroxypropyl-β-cyclodextrin in the base liquid obtained in the above steps, and stir for 10 minutes under the conditions of a rotation speed of 200rpm and a temperature of 23°C to obtain 58g of a light brown clear solution, which is inclusion agent.

[0053] Put the inclusion agent into a beaker, slowly add 0.5g of agarwood essential oil dropwise under stirring condition, until the dropwise addition is complete, continue to stir for 30min, and then let stand to obtain a woody aroma slow-release agent. The stirring conditions are as follows: the rotational speed of the mechanical stirring is 180 rpm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com