A kind of graphene base cigarette paper and preparation method thereof

A graphene-based, cigarette paper technology, applied in papermaking, paper, paper coatings, etc., can solve the problems of not being able to give individualized visual effects at the same time, short retention time of aroma substances, affecting the quality of cigarette products, etc., so as to improve the quality of cigarette products , the effect of prolonging retention time, saving raw material costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

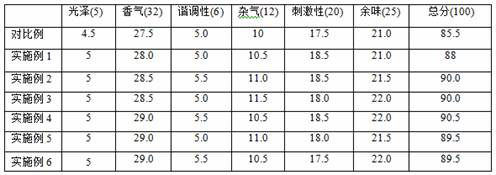

Examples

Embodiment 1

[0031] (1) Weigh 500 g of graphene oxide, soak it in 5 L of deionized water / ethanol mixed solvent (V / V=5:1) for 2 h, and ultrasonicate for 0.5 h at room temperature in an ultrasonic device with a power of 100 W to obtain Uniformly dispersed graphene oxide dispersion; wherein, the sheet size of graphene oxide is 10-20 μm, the thickness is 2.0-4.0 nm, and the C / O is 3:1;

[0032] (2) Add 50 g of glycerol humectant, 100 g of coffee arabica extract, and 5 g of tea polyphenols to the graphene oxide dispersion obtained in step (1), stir evenly for 1.5 h, and mix well. Obtain graphene functional compound after homogeneous;

[0033] (3) Spin-coat the graphene functional composite obtained in step (2) on the surface of cigarette paper, and the coating amount is 10 g / m of graphene composite 2 , and then dried at 110 °C for 1 min to obtain graphene-based cigarette paper. According to the conventional cigarette paper processing technology, the upper rolling machine is used for cigarette...

Embodiment 2

[0036] (1) Weigh 350 g of graphene oxide, soak it in 1 L of deionized water / propylene glycol mixed solvent (V / V=7 / 2) for 2 h, and ultrasonicate at room temperature for 1 h in an ultrasonic device with a power of 100 W. Obtain a uniformly dispersed graphene oxide dispersion; wherein, the sheet size of graphene oxide is 13-18 μm, the thickness is 2.5-3.5 nm, and the C / O is 3:1; (2) the oxidized Add 10 g combustion enhancer sodium citrate, 20 g honey humectant, 500 g Dali plum extract, and 20 g taste regulator citric acid to the graphene dispersion, stir evenly for 2 h, and obtain graphene functional compound after fully mixing thing;

[0037] (3) Spray the graphene composite obtained in step (2) on the surface of the cigarette paper, and the coating amount is 5g / m of the graphene composite 2 , and then dried at 110 °C for 30 s to obtain graphene-based cigarette paper. According to the conventional cigarette paper processing technology, the upper rolling machine is used for cig...

Embodiment 3

[0040] (1) Weigh 1 kg of graphene oxide, soak it in 9 L of deionized water / ethanol / propylene glycol (V / V=6 / 1) for 2 h, and ultrasonicate for 2.5 h at room temperature in an ultrasonic device with a power of 100 W. Obtain a uniformly dispersed graphene oxide dispersion; wherein, the sheet size of graphene oxide is 10-20 μm, the thickness is 2.0-4.0 nm, and the C / O is 3:1; (2) the oxidized Add 2 kg of Rosa roxburghii extract, 20 g of sodium citrate as a combustion enhancer, 50 g of tobacco polysaccharide humectant, and 10 g of dextran as a sweetener to the graphene dispersion, stir for 1.5 h, and mix thoroughly to obtain graphite ene functional complexes;

[0041] (3) Spray the graphene composite obtained in step (2) on the surface of the cigarette paper according to the designed auspicious cloud pattern, and the coating amount is 7 g / m of graphene composite 2, and then dried at 110 °C for 10 s to obtain graphene-based cigarette paper applications. According to the conventiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com