Addition-type liquid fluorosilicone rubber inhibitor and preparation method thereof

A technology of rubber inhibitor and liquid fluorosilicone, which is applied in the field of rubber materials, can solve the problems of inhibitor volatilization loss and poor compatibility of fluorosilicone rubber system, and achieve the effect of solving volatilization loss, good compatibility and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

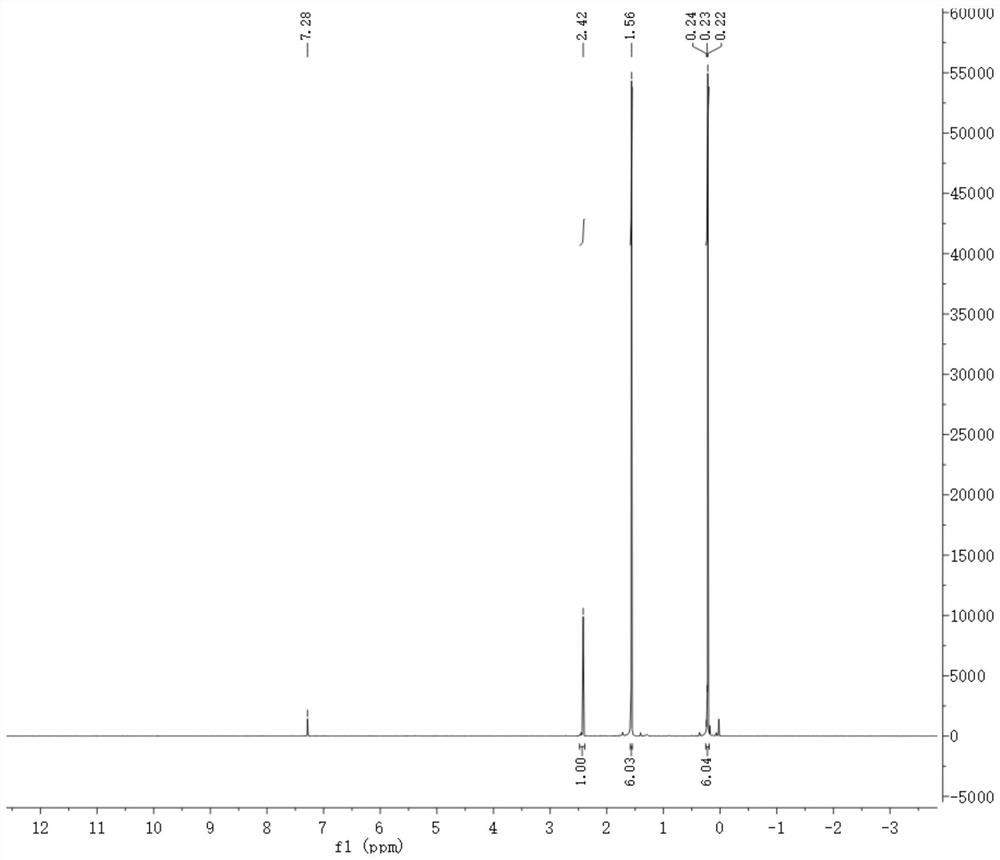

[0049] An additively molded liquid fluorosilicone rubber inhibitor with the following structure:

[0050]

[0051] The preparation steps are as follows:

[0052] (1) Under the protection of nitrogen, to the reactor equipped with mechanical stirring, thermometer, condensing tube, drip funnel added 1340g tetramethyldisiloxane, 1500g toluene and 12.6g tri (pentafluorophenyl) borane, open the stirring and heat up to 40 °C, and then slowly add 1764g 2-methyl-3-butyne-2-ol to the kettle for dehydrogenation reaction, during the drip addition of a large amount of exothermic heat, by the drip acceleration of the kettle temperature regulation, maintain the reaction temperature of the entire drip process of 40 °C ~ 50 °C, After the drop addition, continue stirring the reaction for 1h;

[0053] (2) Reduce the reaction system to room temperature and add 76g of hydrotallite [Mg] to the kettle 6 Al 2 (OH) 16 CO 3 .4H 2 O] and 80 g of diatomaceous earth stirred to neutralize for 2 h, and then n...

Embodiment 2

[0057] An additively molded liquid fluorosilicone rubber inhibitor with the following structure:

[0058]

[0059] The preparation steps are as follows:

[0060] (1) Under the protection of nitrogen, add 1340g of tetramethyldisiloxane, 2000g of toluene and 17.5g of tris(pentafluorophenyl) borane to the reactor equipped with mechanical stirring, thermometer, condensing tube, and drip funnel, turn on stirring and heat up to 40 °C, and then slowly add 1848g of 2-methyl-3-butyne-2-ol to the kettle for dehydrogenation reaction, during the drop-addition of a large amount of exothermic heat, through the drop acceleration of the kettle temperature regulation, maintain the reaction temperature of the entire drip process of 40 °C ~ 50 °C, After the drop addition, continue stirring the reaction for 2h;

[0061] (2) Reduce the reaction system to room temperature and add 105g of hydrotallite [Mg] to the kettle 6 Al 2 (OH) 16 CO 3 .4H 2 O] and 100 g of diatomaceous earth stirred to neutralize...

Embodiment 3

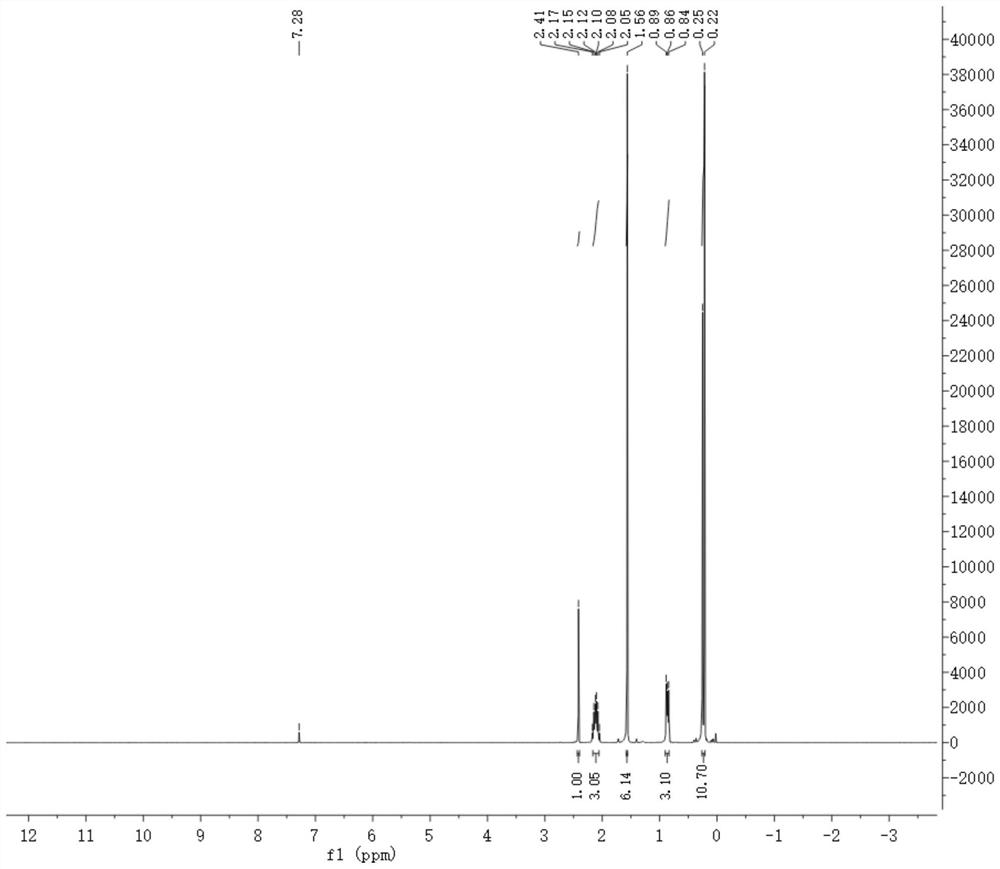

[0064] An additively molded liquid fluorosilicone rubber inhibitor with the following structure:

[0065]

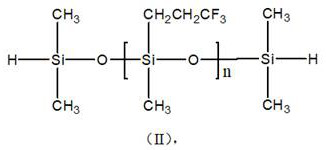

[0066] The preparation steps are as follows:

[0067] (1) To the reactor equipped with mechanical stirring, thermometer, condensing tube was added 468g trimethyltris(3,3,3-trifluoropropyl) cyclotrisiloxane (D 3 F) and 268g tetramethyldisiloxane, stirred evenly, using an ice water bath to reduce the kettle temperature to 10 °C ~ 15 °C Then slowly add 3.6g of trifluoromethanesulfonic acid to the kettle for cationic catalytic ring-opening polymerization reaction, reaction exothermic, cooling in an ice water bath, after the end of the punching temperature, maintain 10 °C ~ 20 °C to continue stirring the reaction for 2h; then add 3.2g of sodium bicarbonate to the kettle to mix the reaction for 3h and filter and filter, collect filtrate; at a pressure of -0.09MPa, heat up to 160 °C to remove unreacted raw materials and small molecules with low boiling point, cool down, and give ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com