Malt preparation process capable of stably controlling Canadian beer malt

A technology for stable control and malting, which is applied in the field of malting technology to stably control the malt color of Canadian beer, can solve the problem of not being able to significantly improve the color stability, so as to improve the color stability, prolong the germination time, and reduce the production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

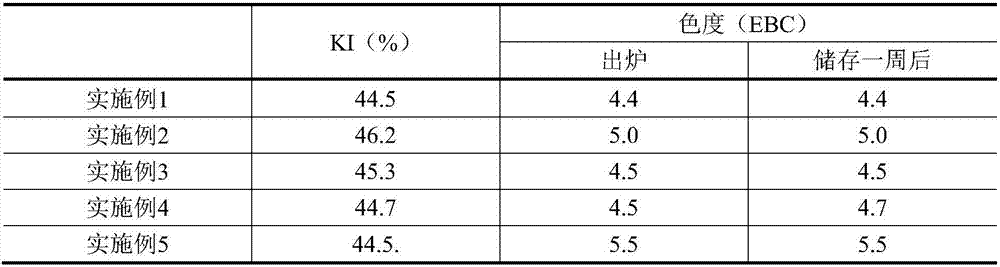

Embodiment 1

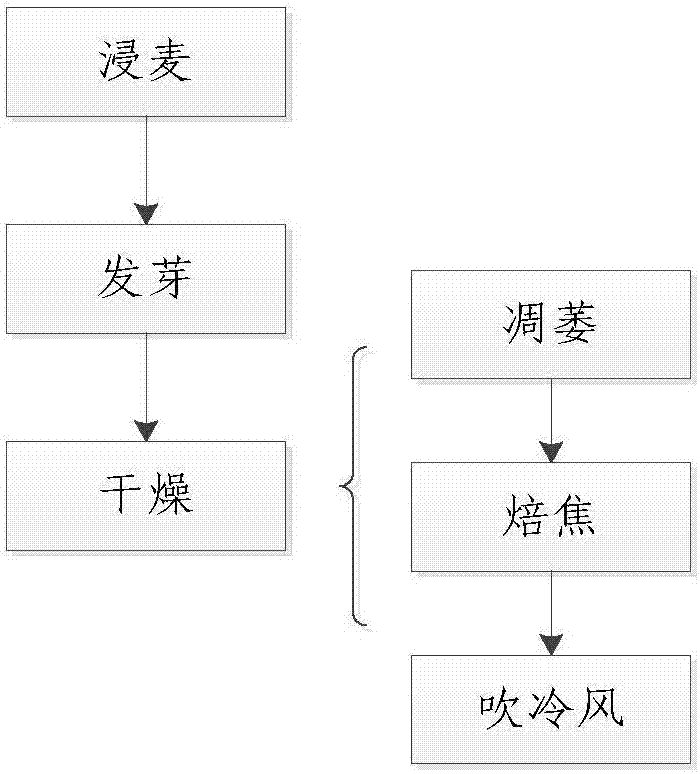

[0022] A malting process that stably controls the color of Canadian beer malt. The cleaned and added malt is soaked, germinated and dried to make Canadian beer malt with stable color. The drying process includes withering, roasting and blowing cold air process. in:

[0023] The wheat soaking process adopts the low-temperature and water-cut wheat soaking method. Four wet soaks and four dry soaks are carried out alternately in sequence. The four wet soaks adopt continuous blowing and overflow. The total soaking time is 30 hours, including: The second dry immersion is carried out alternately in sequence. The four times of wet immersion adopt continuous blowing and overflow. The water temperature for leaching wheat is 11°C, 12°C, 12°C and 13°C in sequence, and the soaking time is: 3 hours, 4 hours. Hours, 3 hours and 2 hours; the four times of dry immersion per ton of barley continuously pumped CO2 under the air volume of not less than 1.23m3 / min, the soaking time was 6 hours, 7 ...

Embodiment 2

[0030] A malting process that stably controls the color of Canadian beer malt. The cleaned and added malt is soaked, germinated and dried to make Canadian beer malt with stable color. The drying process includes withering, roasting and blowing cold air process. in:

[0031] The wheat soaking process adopts the low-temperature water-cut wheat soaking method, four times of wet soaking and four times of dry soaking are carried out alternately, and the fourth wet soaking adopts continuous blast and overflow, and the soaking water temperature is 12°C, 13°C, 13°C and 14°C. ℃, the soaking time is as follows: 3 weeks, 4 weeks, 3 weeks and 2 weeks; the air volume per ton of barley for four times of dry soaking is not less than 1.23m 3 Continuous pumping of CO at / min 2 , the soaking time is 6 days, 7 days, 4 days and 1 day in turn, and the fresh air ratio is 70%; after the soaking, the wheat soaking degree is 44.2%, and the outcropping rate is not less than 85%;

[0032] The germina...

Embodiment 3

[0038] A malting process that stably controls the color of Canadian beer malt. The cleaned and added malt is soaked, germinated and dried to make Canadian beer malt with stable color. The drying process includes withering, roasting and blowing cold air process. in:

[0039] The wheat soaking process adopts the low-temperature water-cut wheat soaking method, four times of wet soaking and four times of dry soaking are carried out alternately, and the fourth wet soaking adopts continuous blast and overflow, and the soaking water temperature is 11°C, 12°C, 12°C and 13°C. ℃, the soaking time is as follows: 3 weeks, 4 weeks, 3 weeks and 2 weeks; the air volume per ton of barley for four times of dry soaking is not less than 1.23m 3 Continuous pumping of CO at / min 2 , the soaking time is 6 days, 7 days, 4 days and 1 day in turn, and the fresh air ratio is 70%; after the soaking, the wheat soaking degree is 43%, and the outcropping rate is not less than 85%;

[0040] The germinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com