Tube internal and external expansion type spiral corrugated tube

A technology of corrugated tubes and helical waves, which is applied in the field of helical corrugated tubes with internal and external expansion, can solve the problems of insignificant improvement of comprehensive heat transfer performance and increased resistance, and achieve the purpose of inhibiting tube wall scaling, reducing resistance, and reducing The effect of flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

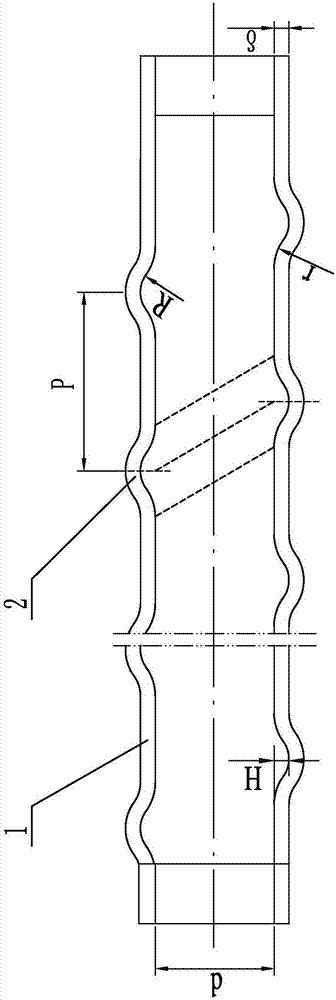

[0014] Specific implementation mode one: combine figure 1 Describe this embodiment mode. The internally and externally expanding helical corrugated tube described in this embodiment comprises a hollow tube body 1. A helical corrugated node channel 2 is provided on the outer peripheral side wall of the hollow tube body 1. The helical corrugated node channel 2 are uniformly arranged in a helical shape along the length direction on the outer peripheral side wall of the hollow pipe body 1, and the cross section of the helical node channel 2 is an arc shape with the middle protruding outward along the radial direction.

[0015] The helical nodal channel 2 is designed in this way to be a channel with a convex structure that spirals inside and outside the hollow tube body 1. The helical nodal channel 2 is formed in the hollow tube body 1 by liquid expansion, and is used to seal the hollow tube body when the fluid passes through. 1 to form a swirl.

[0016] The fluid forms vortices w...

specific Embodiment approach 2

[0017] Specific implementation mode two: combination figure 1 This embodiment will be described. The helical nodal channel 2 in this embodiment is arranged in a counterclockwise direction on the outer peripheral side wall of the hollow tubular body 1 . Other compositions and connection methods are the same as those in Embodiment 1.

[0018] The fluid in the hollow tube body 1 flows through the helical structure in such a design, which can increase the fluid disturbance and increase the heat exchange effect. At the same time, the helical structure has the effect of rectification, allowing the fluid to obtain the normal phase velocity, forming a swirling flow, reducing flow resistance, and increasing the heat exchange time. To sum up, the spiral structure can improve the comprehensive heat transfer performance of the heat exchange tube.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination figure 1 This embodiment will be described. The height H of the helical nodal channel 2 in this embodiment is 2.5 mm. Other compositions and connection modes are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com