Construction method of time-varying dynamic model for high-feed turning external thread parts

A technology of mechanical model and construction method, applied in the direction of instrumentation, geometric CAD, calculation, etc., can solve the problem that the machining accuracy and surface integrity of the left and right thread surfaces are difficult to guarantee the high-performance service of the tool, cannot reveal the chatter phenomenon, and cannot reflect the thread Processing path and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

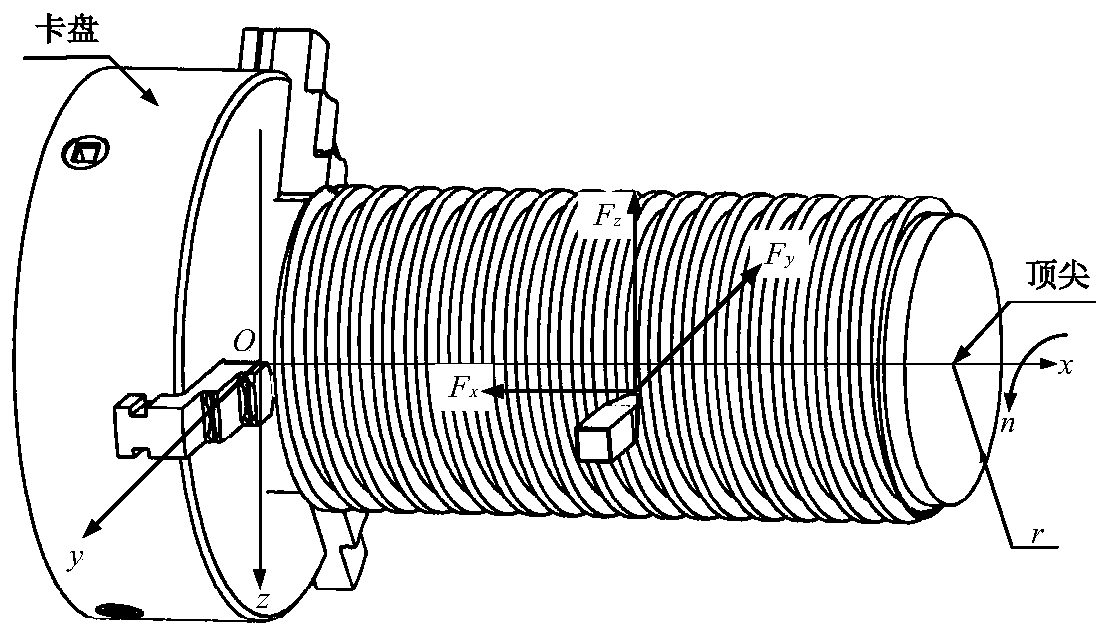

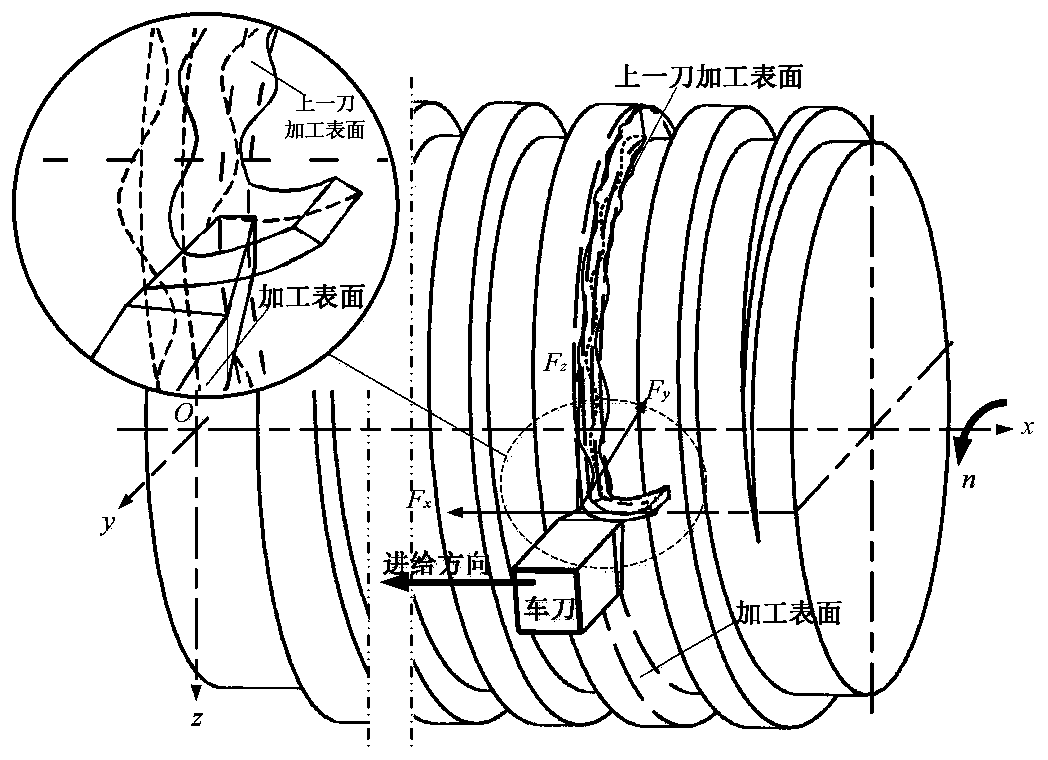

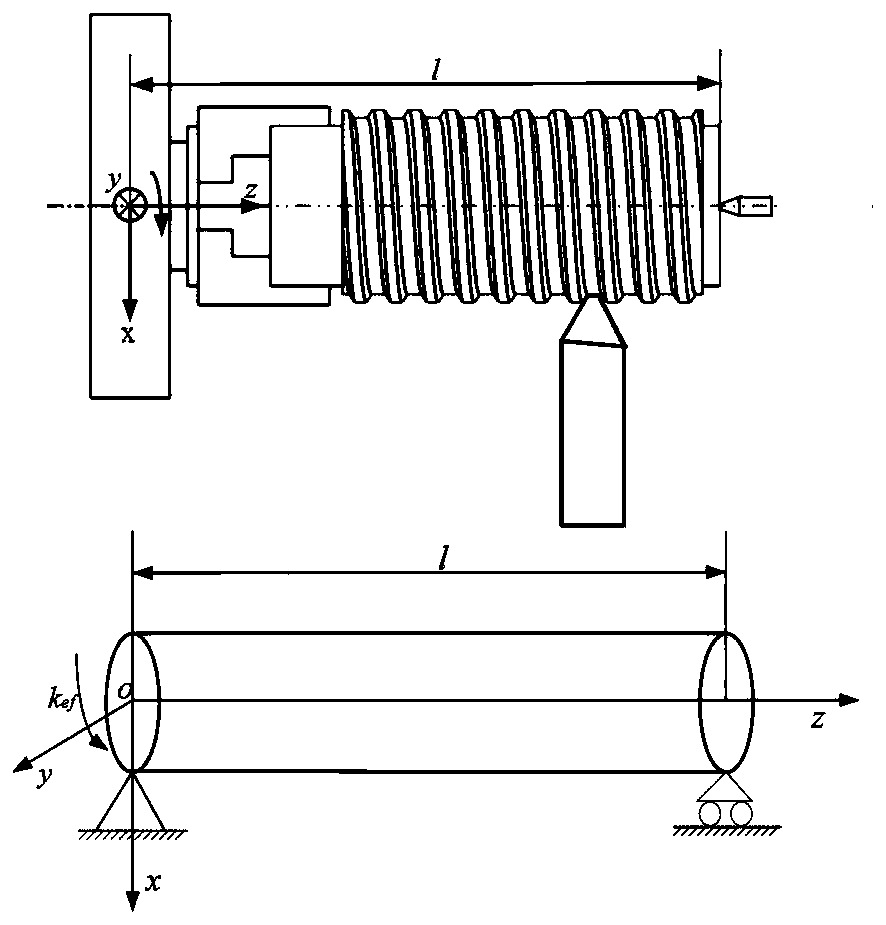

[0092] See Figure 1-6 , a method for establishing a time-varying dynamic model for high-feed turning external threaded parts, the steps are:

[0093] (1) On the basis of the Rayleigh beam vibration theory, the strain energy and kinetic energy of large-pitch external threaded parts are solved when the tool is cutting radially along the helical trajectory;

[0094] (2) Considering the "regeneration-like effect" on the surface of the workpiece to modify the existing instantaneous cutting force model and solve it numerically;

[0095] (3) Describe and solve the boundary conditions when turning threaded parts through the mode shape function;

[0096] (4) Establish and solve the vibration model of the workpiece according to the principle of virt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com