SNCR (Selective Non-Catalytic Reduction) nozzle device used for pi-type corner tangential boiler

A technology of nozzle device and four-corner tangential circle, applied in injection device, gas treatment, membrane technology, etc., can solve the problems of uneven nitrogen concentration at the outlet, high dust content, low denitrification efficiency, etc., and achieve good coal quality change and load change , Improve denitrification efficiency and facilitate maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

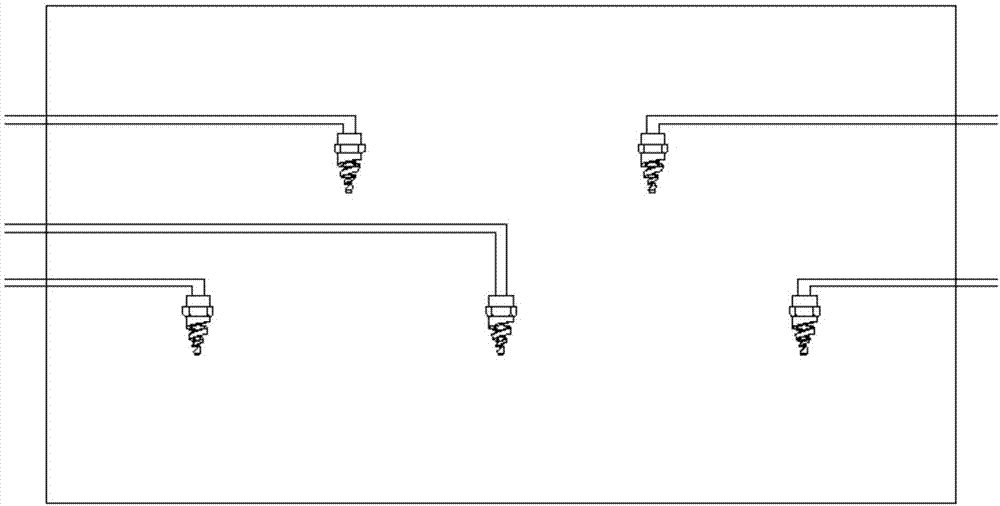

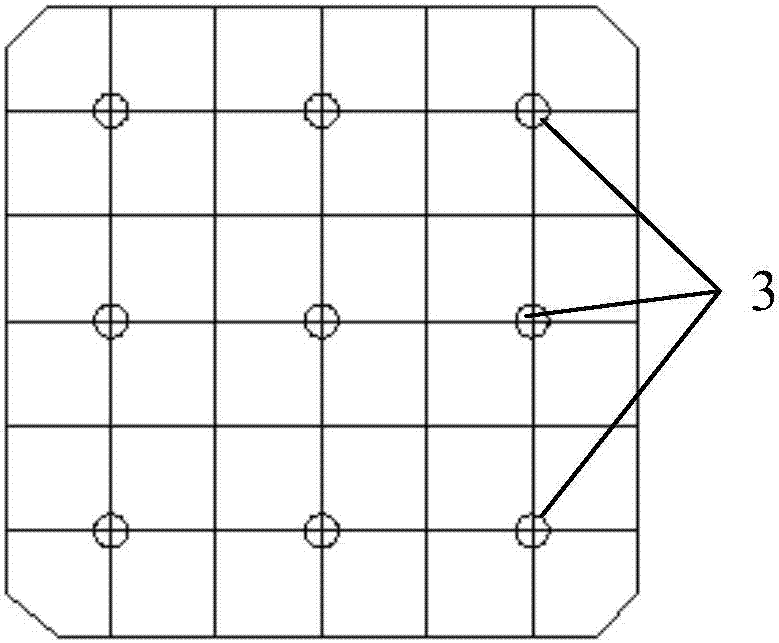

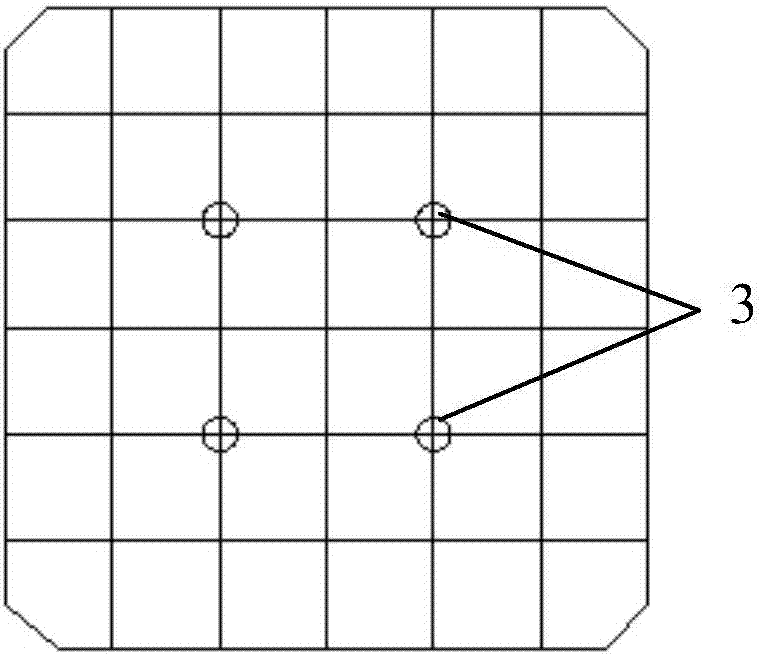

[0025] In order to better understand the purpose, structure and function of the present invention, a SNCR nozzle device for a π-shaped four-corner tangential circle boiler according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] Such as Figure 1 to Figure 4 As shown, it is shown as an SNCR nozzle device for a π-shaped four-corner tangential circle boiler according to the present invention, which includes a plurality of nozzles 3, which are respectively layered and intersected in the furnace, and the nozzles 3 are fixed on the furnace wall through the nozzle 1. The upper main pipe (not shown in the figure) is connected, and the denitrification reducing agent is received through the nozzle 1, and the length of the nozzle 3 extending into the furnace can be adjusted to adjust the height of the nozzle 3 so that the nitrogen oxides (NOx) in the flue gas X ) and ammonia fully contact and mix evenly, improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com