Laser focus control system, application thereof and laser cleaning head

A control system and laser cleaning technology, which is applied in the laser field, can solve problems such as the inability to realize cleaning in narrow spaces, and can not meet the cleaning requirements, so as to improve the quality and efficiency of cleaning, facilitate implementation, and ensure accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1 laser cleaning

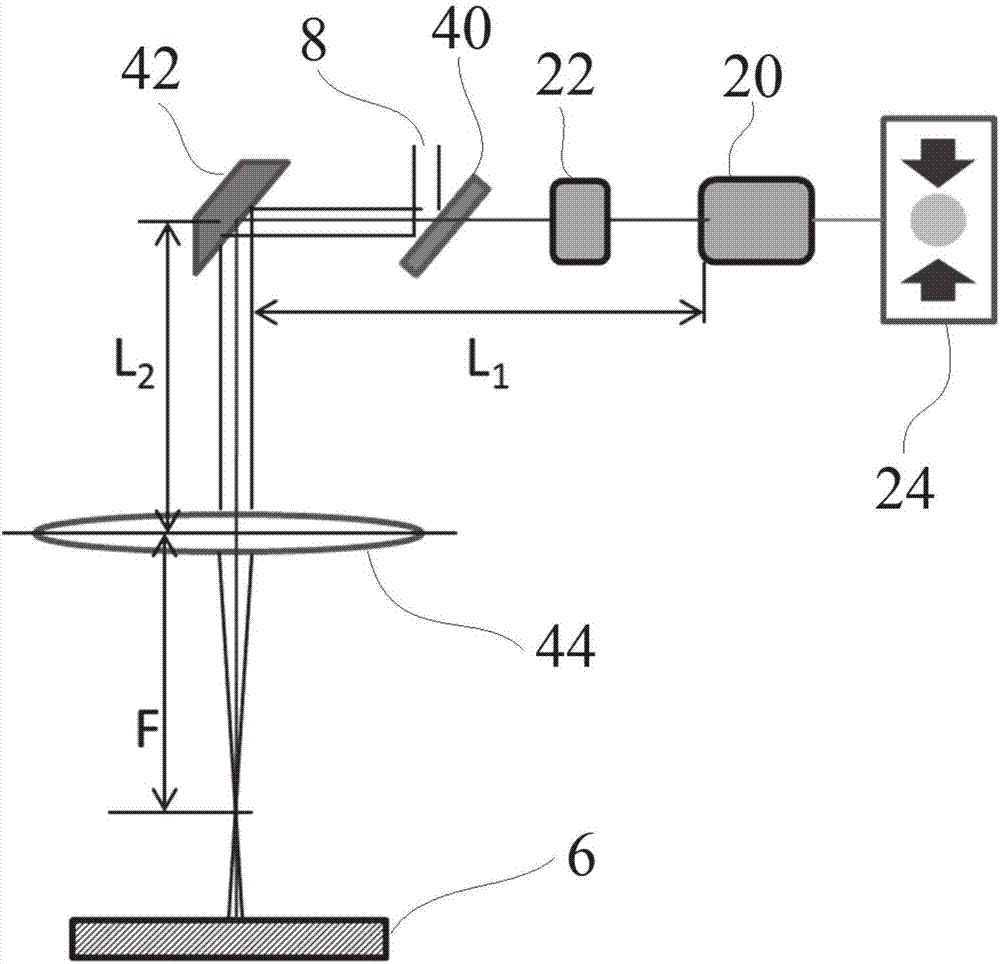

[0070] The laser focus control system in this embodiment is as figure 1 As mentioned in the above, it includes: a laser range finder 20 , a filter 22 , a calculation display unit 24 , a beam splitter 40 , a scanning galvanometer 42 , a field mirror 44 , and a working laser 8 . In this embodiment, the working laser 8 is a cleaning laser.

[0071] Specifically, the ranging laser beam emitted by the laser rangefinder 20 passes through the filter 22, passes through the beam splitter 40 and shoots to the scanning galvanometer 42 on the same optical path as the working laser 8 reflected by the beam splitter 40, and the scanning galvanometer 42 After reflection, it passes through the field lens 44 to irradiate the surface of the workpiece 6 to be processed and measure the distance to obtain the distance measurement result L. In this embodiment, the workpiece 6 to be processed is the workpiece to be cleaned.

[0072] Wherein, the calculation and...

Embodiment 2

[0090] Embodiment 2 laser cleaning

[0091] Use a handheld laser cleaning device to clean the rusty carbon steel material, replace the field lens 44, and reset ΔF according to the focal length F of the new field lens 44 and the material to be cleaned.

[0092] The cleaning head of the handheld laser cleaning device adopts a laser focus control system, and its schematic diagram is as follows figure 1 Shown, its mode of operation is the same as embodiment 1.

Embodiment 3

[0093] Embodiment 3 laser texture

[0094] The laser focus control system in this embodiment is as figure 1 As mentioned in the above, it includes: a laser range finder 20 , a filter 22 , a calculation display unit 24 , a beam splitter 40 , a scanning galvanometer 42 , a field mirror 44 , and a working laser 8 . In this embodiment, the working laser 8 is a processing laser.

[0095] Specifically, the ranging laser beam emitted by the laser rangefinder 20 passes through the filter 22, passes through the beam splitter 40 and shoots to the scanning galvanometer 42 on the same optical path as the working laser 8 reflected by the beam splitter 40, and the scanning galvanometer 42 After reflection, it passes through the field lens 44 to irradiate the surface of the workpiece 6 to be processed and measure the distance to obtain the distance measurement result L. In this embodiment, the workpiece 6 to be processed is the material to be processed.

[0096] Wherein, the calculation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com