Production device for aerated brick slurry

A production device and technology for aerated bricks, which are applied in the direction of selling raw material supply devices, clay preparation devices, cement mixing devices, etc., can solve the problems of uneven stress and easy cracking of aerated bricks, and achieve uniform internal pore size The effect of low production costs, low manufacturing and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

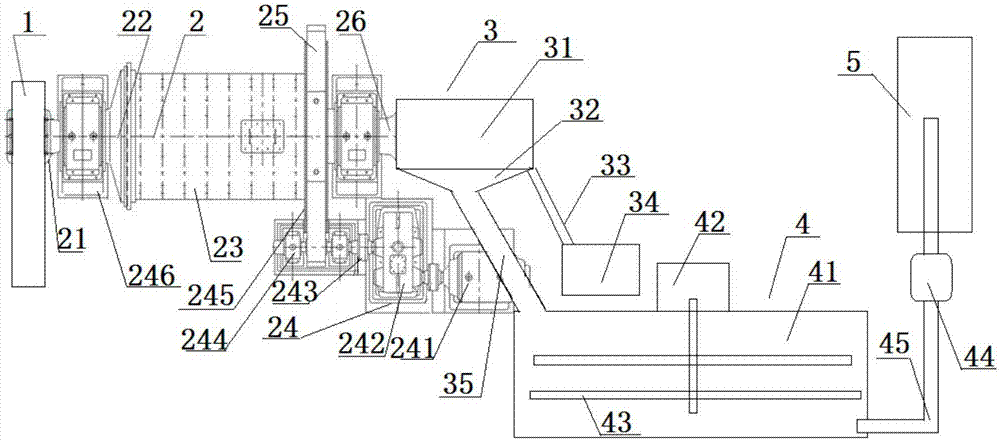

[0034] The production device of the aerated brick slurry of the present embodiment, such as figure 1 As shown, it includes a feeding mechanism 1, a wet milling mechanism 2, a temporary storage mechanism 4 and a filtering mechanism 3, wherein: the feeding mechanism 1 can be a hoist or a belt conveyor, the wet grinding mechanism 2 can be a wet ball mill, and the filtering mechanism 3 can be It is a filter screen, and the temporary storage mechanism 4 can be a temporary storage tank. The feeding mechanism 1 feeds materials to the wet grinding mechanism 2, and the wet grinding mechanism 2 communicates with the filtering mechanism 3; the slurry filtered by the filtering mechanism 3 is directly passed into Inside the temporary storage mechanism 4 .

[0035] The production device of the aerated brick slurry in this embodiment, through the setting of the filter mechanism 3, the large particles in the slurry after wet grinding are filtered, and then passed into the temporary storage me...

Embodiment 2

[0037] The production device of aerated brick slurry in this embodiment has the same basic structure as that of Embodiment 1, the difference and improvement are that: the wet grinding mechanism 2 includes a material receiving port 21, a feeding port 22, a ball mill cylinder 23 and The discharge port 26 also includes a power part 24 that provides the rotational power of the ball mill cylinder 23; the discharge port 21 is externally connected to the blanking port of the feeding mechanism 1; the discharge port 26 is externally connected to the feed port of the filter mechanism 3, A unified integral structure is formed, the production process is smooth and the efficiency is high. The filter mechanism 3 is a rotary drum filter, including a net cylinder 31, a material receiving port 32, a slag discharge pipe 33 and a slag collection box 34; the net cylinder 31 is directly fixedly connected with the discharge port 26, and synchronized with the ball mill cylinder Rotate; the receiving...

Embodiment 3

[0039] The production device of aerated brick slurry in this embodiment has the same basic structure as that of Embodiment 2, the difference and improvement are that: the power part 24 includes a transmission-type connected motor 241, a reducer 242, a shaft coupling 243, and a belt bearing 244 , belt 245, main bearing 246 and driving and passive belt pulley, driving belt pulley is fixed on the transmission shaft of speed reducer 242, and driven belt pulley is fixed on the ball mill barrel 23. Belt-type transmission, the rotation of the net cylinder 31 and the ball mill cylinder 23 is seamless, and the stability of abrasive and filtration is strong. Main bearings 246 can be set to two, arranged on both sides of the ball mill cylinder 23, to improve the stability of the wet grinding of the ball mill cylinder 23; said belt bearings 244 are also two, arranged on both sides of the driving pulley, can Improve the stability of pulley rotation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com