A kind of printing method of jet photosensitive polymer 3D printer

A photopolymer, 3D printer technology, applied in the field of 3D printing, can solve the problems of affecting the printing effect and the mismatch of the distance between the photopolymer and the downward movement of the table, and achieve high accuracy of calculation, prevention of height changes, and reliable data. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

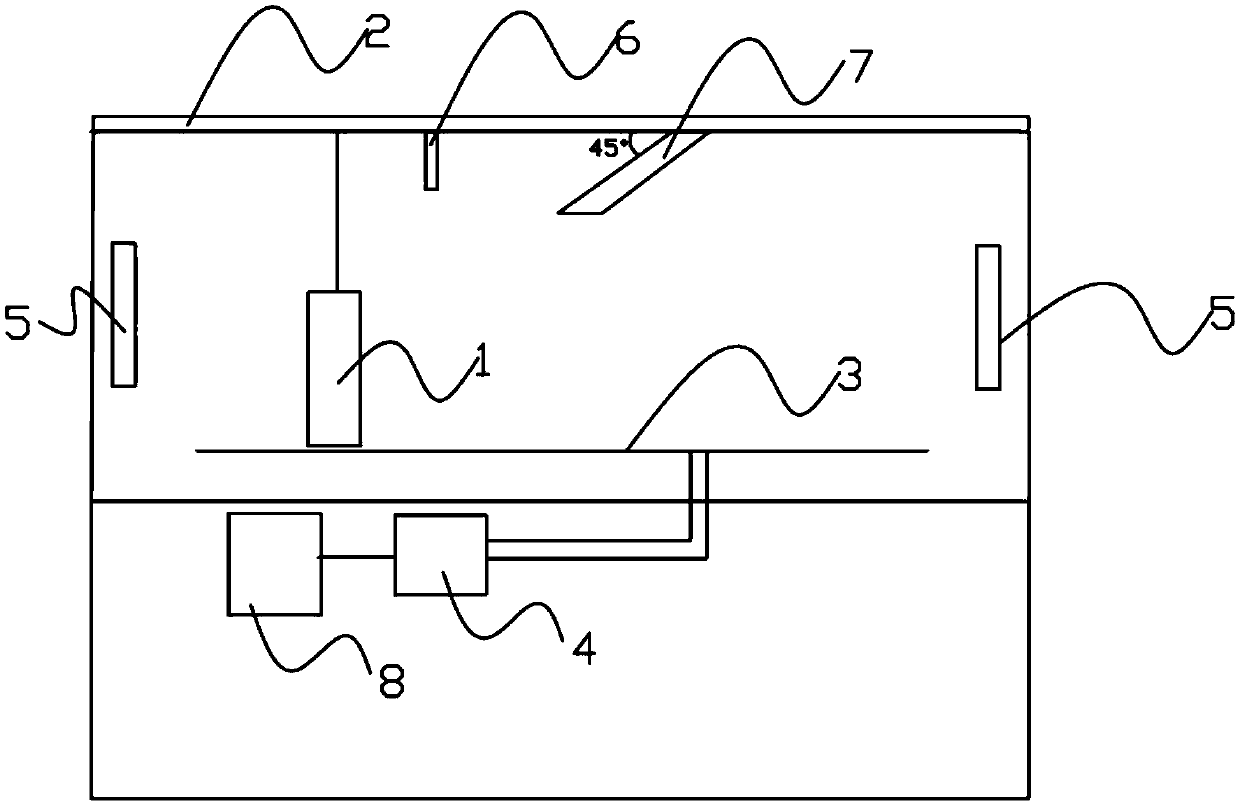

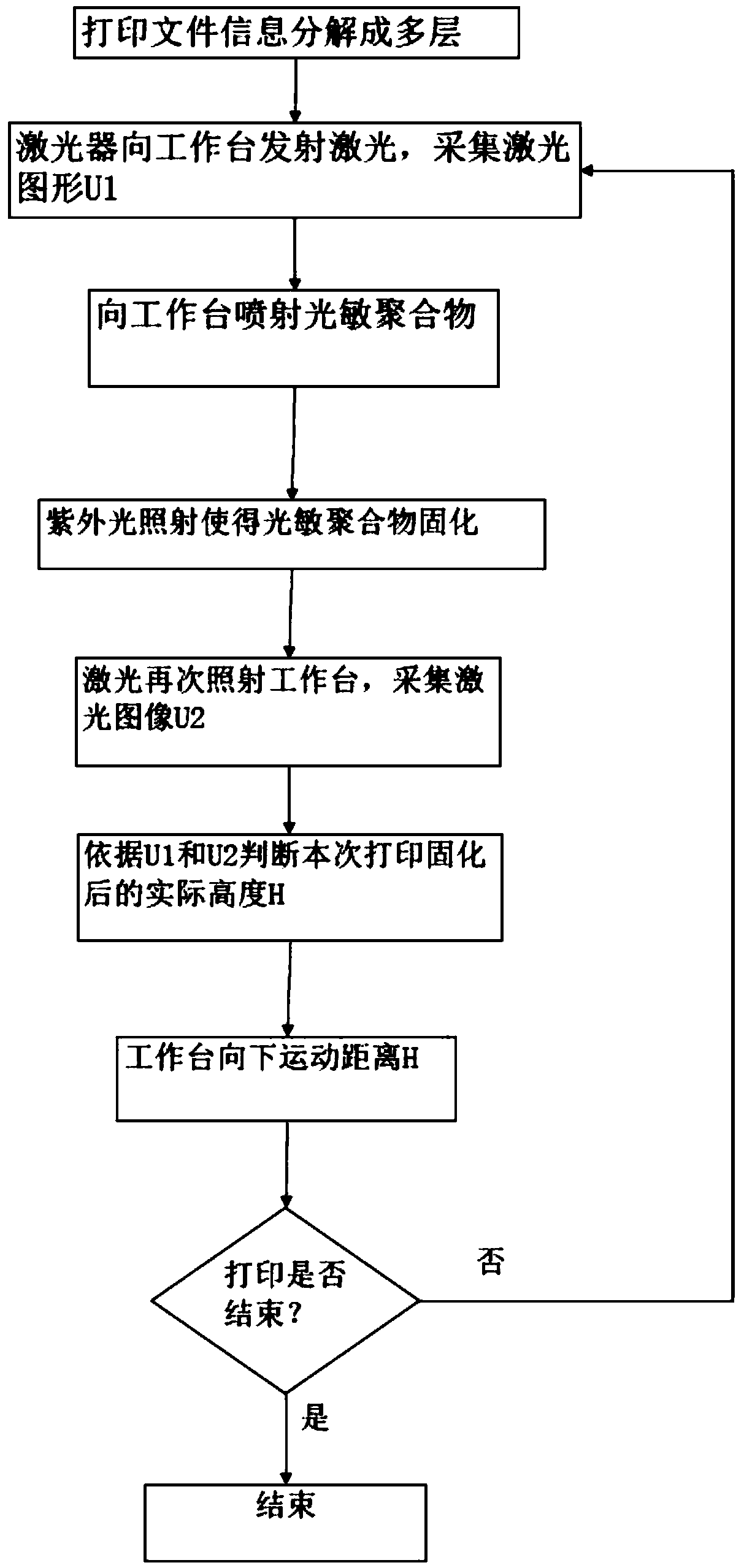

[0026] see Figure 1-2 As shown, the 3D printer includes a nozzle 1, a guide rail 2, a workbench 3, a driving device 4, a UV lamp 5, a laser generator 6, an image detection device 7, and a main control board 8; the nozzle 1 and the guide rail 2 Located above the workbench 3, the spray head 1 can move above the workbench 3 along the guide rail 2. The first driving device 4 includes a first motor 41 and a transmission device 42. One end of the transmission device is connected to the first motor, and the other end is connected to the The workbench 3, the transmission device 42 drives the workbench 3 to move up and down, the laser generator 6 is located above the workbench 3 and the laser light emitted by the laser generator 6 is perpendicular to the workbench, the laser generator can move along the horizontal direction, and the imaging device 7 is located on the Above the workbench 3, and forming an included angle of 45 degrees with the workbench, the UV ultraviolet lamp 5 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com