A Quantitative Nano Heating Stage for Electron Microscopy

A technology of electron microscope and heating stage, which is applied in the direction of material analysis by using wave/particle radiation, material analysis by measuring secondary emissions, circuits, etc. It can solve the problems of sample deviation, influence on in-situ imaging, and high price, and achieve Avoid height changes, facilitate temperature control, and reduce the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below in conjunction with accompanying drawing:

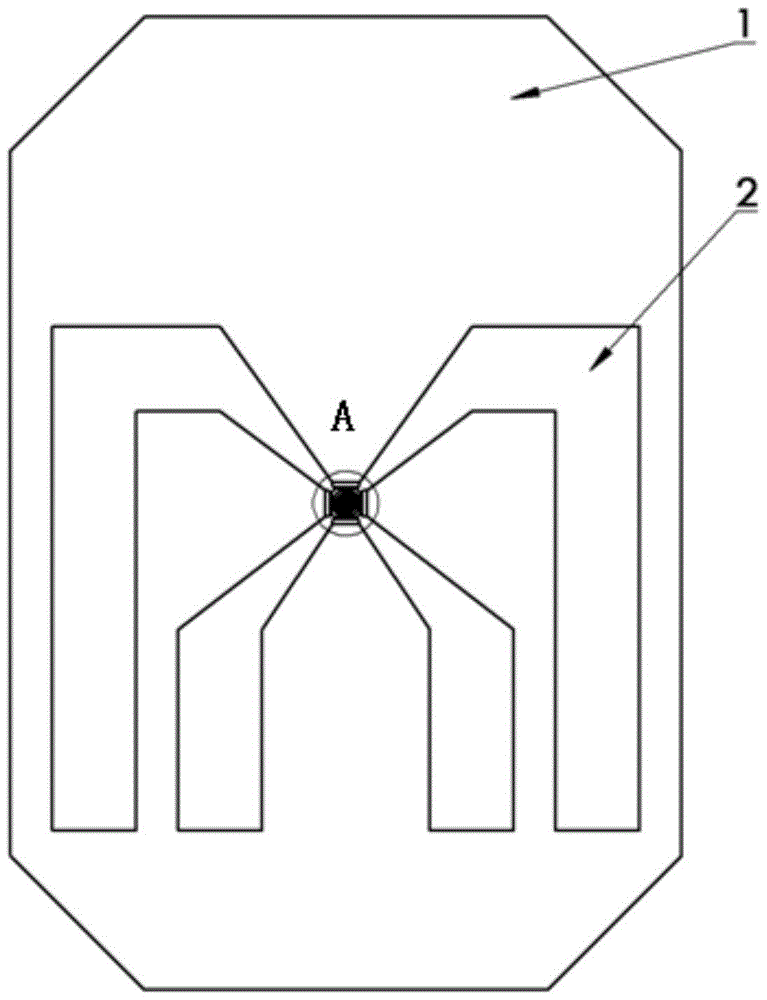

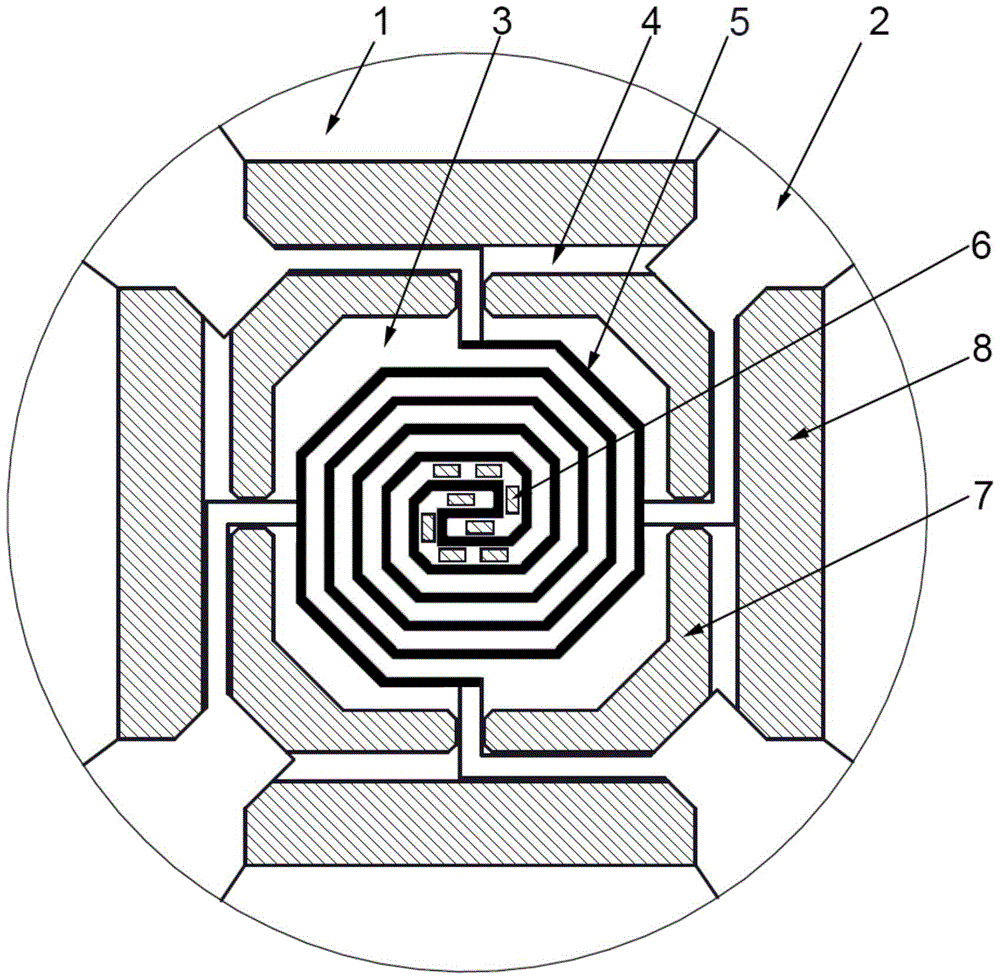

[0030] refer to figure 1 , figure 2 , image 3 , The quantitative nano-heating stage for electron microscope of the present invention includes a substrate 1, a nano-heating stage 3, a flexible connector 4, a heating test resistor 5, a wire 2, and a sample observation hole 6.

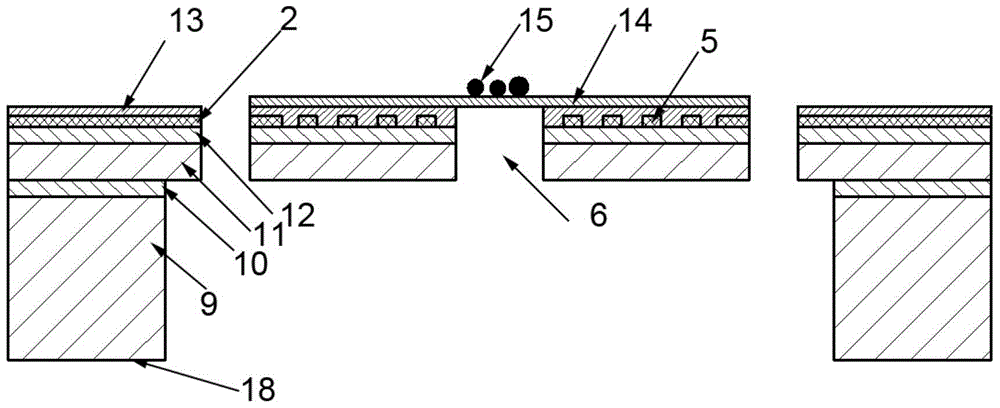

[0031] The quantitative nano-heating table for electron microscope of the present invention is processed by MEMS technology, with the outer surface of the substrate layer 9 as the base surface 18, from bottom to top is divided into substrate layer 9, silicon dioxide intermediate layer 10, top Silicon layer 11, insulating layer 12, wire layer 2 / heating test resistance layer 5, surface protection layer 13, sample supporting film layer 14. The substrate 1 is a chamfered rectangle with a square through hole in the center, which is composed of a substrate layer 9, a silicon dioxide intermediate la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com