Mechanical transmission type material charger

A technology of mechanical transmission and packing machine, which is applied in solid separation, loading/unloading, sieving and other directions, can solve the problems such as the lack of screening effect of materials, the inability to achieve high-efficiency improvement of packing purity, and the inability to effectively filter impurities, etc., to achieve high efficiency and convenience. Intuitive control of the effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

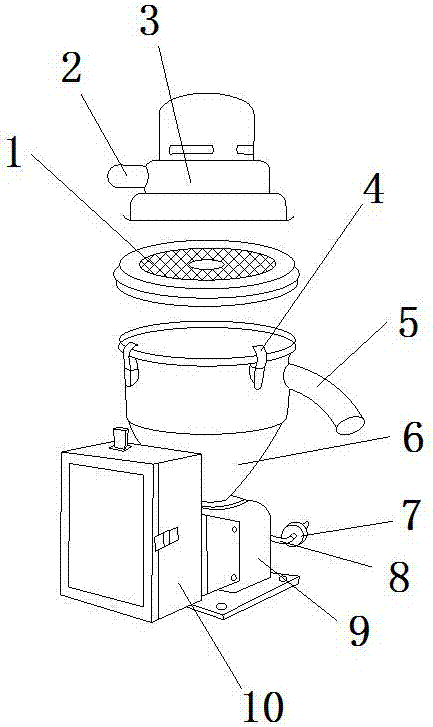

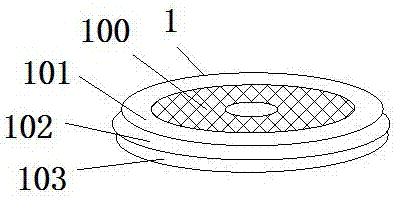

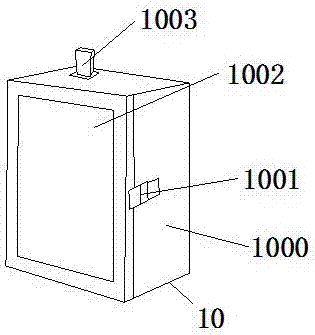

[0021] see Figure 1-Figure 3 , the present invention provides a mechanical transmission type filling machine: its structure includes: shaft-rotating filter screen 1, air outlet 2, air pump 3, spring buckle 4, material suction port 5, storage hopper 6, balance weight 7, balance bar 8. Filling machine base 9, distribution box 10, the air outlet 2 is welded horizontally on the left side of the air pump 3, the air pump 3 is vertically installed on the storage hopper 6 and mechanically connected by a spring buckle 4, the The material suction port 5 is horizontally welded on the right side of the storage hopper 6, and the axes of the shaft-rotating filter screen 1, the air pump 3, and the storage hopper 6 are collinear;

[0022] The shaft-rotating fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com