Thermoplastic film winding device for quantified cutting

A winding device and thermoplastic film technology, which is applied in the direction of winding strips, transportation and packaging, and sending objects, can solve the problems of troublesome operation, large errors, and easy retraction of thermoplastic films, etc., to achieve simple and convenient operation, The effect of saving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail through specific embodiments below.

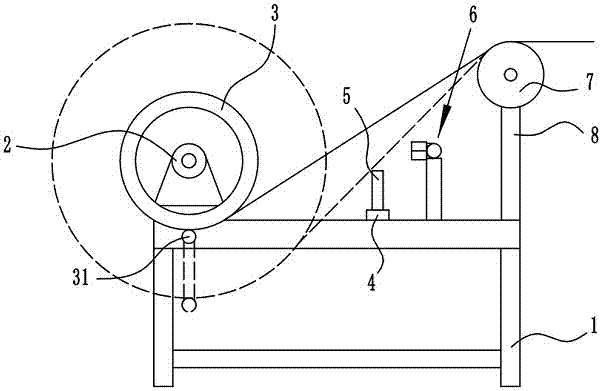

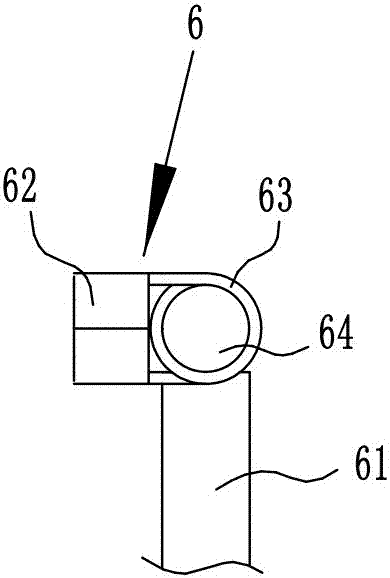

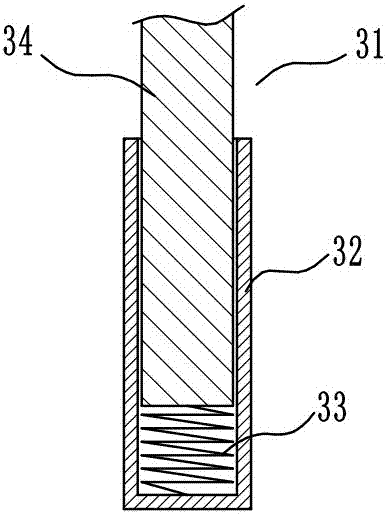

[0023] The reference signs in the accompanying drawings of the description include: bracket 1, motor 2, reel 3, support 4, cutter 5, positioning mechanism 6, transition roller 7, support rod 8, telescopic arm 31, outer sleeve 32, pull Spring 33, inner bar 34, spring seat 61, block 62, torsion spring 63, cross bar 64.

[0024] Thermoplastic film rewinding device for quantitative cutting, such as figure 1 with figure 2 As shown, the motor 2 for providing power is installed on the left side of the support 1, and the coil material reel 3 is installed on the output shaft of the motor 2. The plastic film is wound on the nostalgia plate, welding the support rod 8 on the right side of the bracket 1, and rotating the transition roller 7 on the support rod 8. When winding the thermoplastic film, first let the thermoplastic film bypass the transition roller 7 Cut in from the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com