Composite proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and dry membrane, which is applied in the field of fuel cells, can solve the problems of insufficient flexibility, mechanical properties and thermal stability, etc., and achieve the effects of good proton conductivity, improved proton conductivity, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] A preparation method of a composite proton exchange membrane, comprising:

[0019] According to the mass ratio of sulfurized zirconia-coated carbon nanotubes and chitosan being 0.1-10:100, the sulfurized zirconia-coated carbon nanotubes and chitosan were prepared respectively. Wherein, the prepared chitosan is made into an acidic solution of chitosan.

[0020] Sulfurized zirconia-coated carbon nanotubes can be prepared by the following methods:

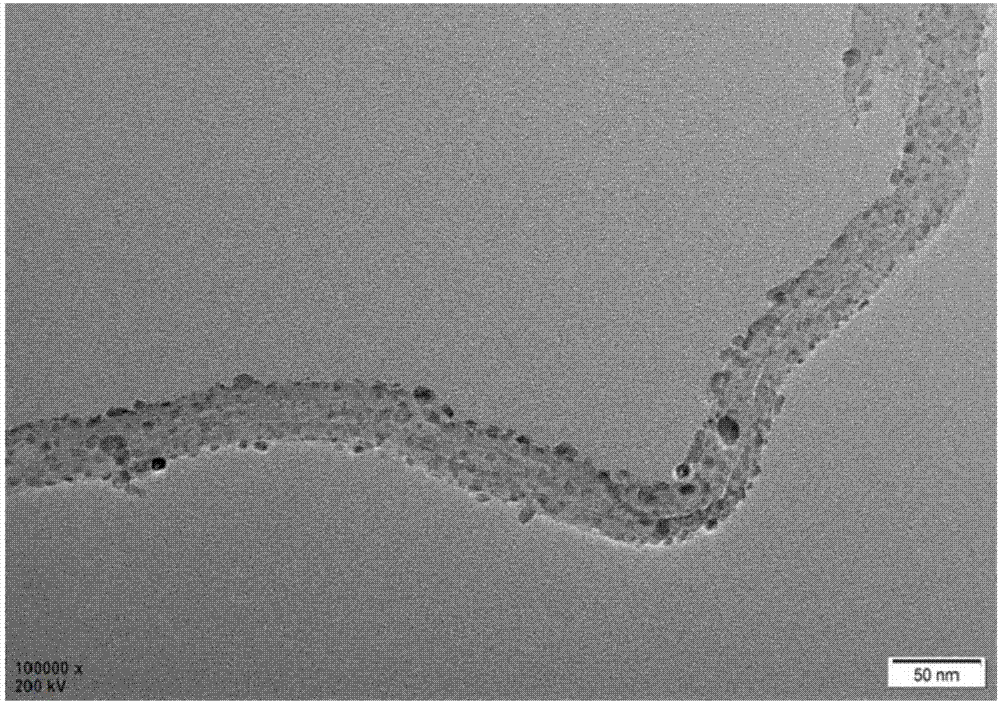

[0021] Add every 1g of carbon nanotubes into every 50-100mL of acid solution and mix evenly, carry out oxidation treatment at 20-120°C for 1-8 hours and then cool, preferably cooling to 20-25°C for the convenience of follow-up deal with. Filtering, washing with water until neutral and drying at a temperature of 60-100° C. are carried out in sequence to obtain acid-oxidized carbon nanotubes. By using acid to oxidize carbon nanotubes, oxygen-containing functional groups are introduced into the surface of carbon nanotubes. Whil...

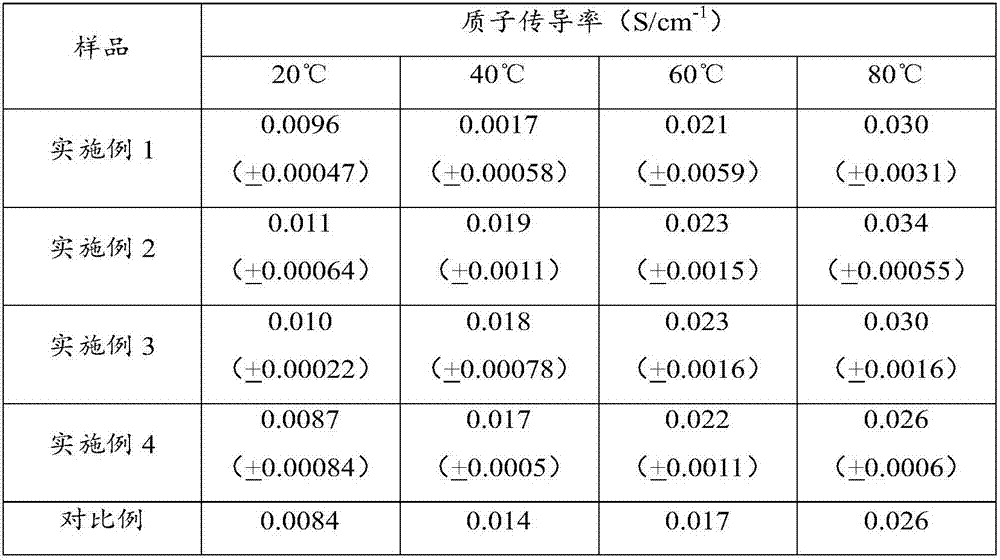

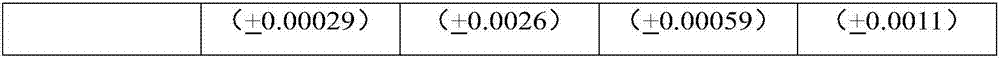

Embodiment 1

[0053] The composite proton exchange membrane was prepared according to the mass ratio of sulfurized zirconia-coated carbon nanotubes and chitosan at 0.1:100.

[0054] Take 1g of carbon nanotubes in 60mL of concentrated nitric acid, oxidize at 30°C for 7h, cool to 20°C, filter, wash with deionized water until neutral, and dry at 60°C to obtain acid oxidation carbon nanotubes. Mix acid-oxidized carbon nanotubes with 0.2 mol / L zirconium oxychloride aqueous solution, add ammonia water dropwise to adjust the pH value between 9 and 10, stir for 24 hours, filter, wash with deionized water until neutral, and Dry at a temperature of 80 °C to obtain the initial sample. The initial sample was added to 0.5mol / L sulfuric acid solution, stirred at 200rpm for 1h, filtered, washed with deionized water until neutral, dried at 80°C, and calcined at 620°C for 1h to obtain Sulfurized zirconia-coated carbon nanotubes.

[0055] Put 0.7g of chitosan with a molecular weight of 1 million into the ...

Embodiment 2

[0059] The composite proton exchange membrane was prepared according to the mass ratio of sulfurized zirconia-coated carbon nanotubes and chitosan at 0.5:100.

[0060] Take 1g of carbon nanotubes in 70mL of concentrated nitric acid and oxidize at 40°C for 6h, cool to 25°C, filter, wash with deionized water until neutral, and dry at 60°C to obtain acid oxidation carbon nanotubes. Mix acid-oxidized carbon nanotubes with 0.2 mol / L zirconium oxychloride aqueous solution, add ammonia water dropwise to adjust the pH value between 9 and 10, stir for 26 hours, filter, wash with deionized water until neutral, and Dry at a temperature of 85°C to obtain the initial sample. The initial sample was added to 0.5mol / L sulfuric acid solution, stirred at 200rpm for 1.5h, filtered, washed with deionized water until neutral, dried at 85°C, and calcined at 600°C for 1.5h , to obtain sulfurized zirconia-coated carbon nanotubes.

[0061] Put 0.7g of chitosan with a molecular weight of 1 million i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com