Polyethylene composite tubular product and manufacturing method thereof

The invention relates to a polyethylene composite pipe and a manufacturing method technology, which can be applied to building structures, building thermal insulation materials, building components, etc., and can solve problems such as poor low temperature resistance, low strength, and maximum operating pressure, and meet the requirements of non-toxic materials and requirements. Low, easy-to-move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

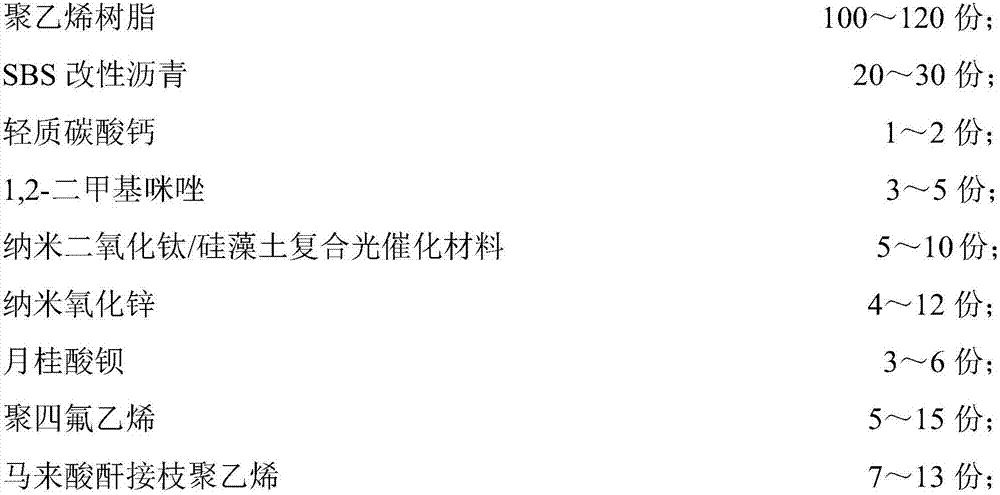

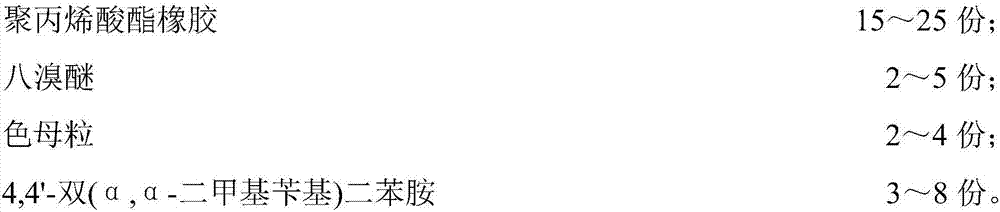

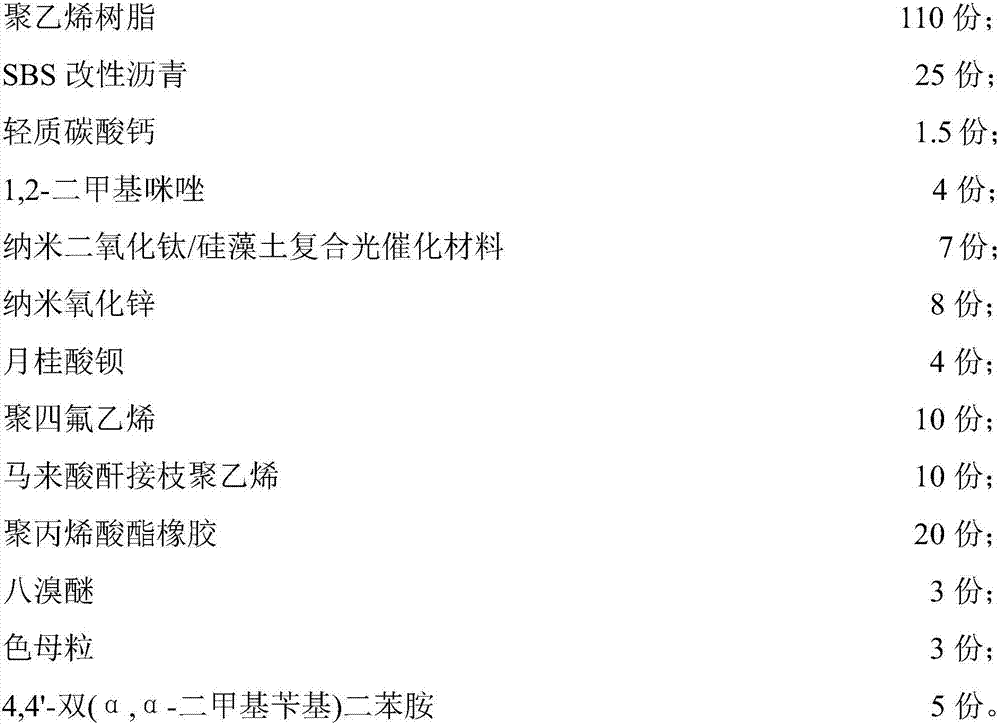

[0100] formula:

[0101] A polyethylene composite pipe of the present invention is mainly composed of the following components in parts by weight: 110 parts of polyethylene resin; 25 parts of SBS modified asphalt; 1.5 parts of light calcium carbonate; 1,2-dimethylimidazole 4 parts; 7 parts of nano-titanium dioxide / diatomite composite photocatalytic material; 8 parts of nano-zinc oxide; 4 parts of barium laurate; 10 parts of polytetrafluoroethylene; 10 parts of maleic anhydride grafted polyethylene; 20 parts of polyacrylate rubber 3 parts of octabromoether; 3 parts of masterbatch; 5 parts of 4,4'-bis(α,α-dimethylbenzyl)diphenylamine.

[0102] Manufacturing process:

[0103] Step 1. Preheat the SBS modified asphalt to 183°C, and preheat the polyethylene resin to 138°C at the same time, and then mix the two evenly.

[0104] Step 2: Add maleic anhydride-grafted polyethylene to the mixture obtained above, stir evenly, and knead in a vacuum kneader for 5 minutes at a kneading temp...

Embodiment 2

[0119] formula:

[0120] A polyethylene composite pipe of the present invention mainly consists of the following components in parts by weight: 100 parts of polyethylene resin; 30 parts of SBS modified asphalt; 2 parts of light calcium carbonate; 1,2-dimethylimidazole 3 parts; 5 parts of nano-titanium dioxide / diatomite composite photocatalytic material; 12 parts of nano-zinc oxide; 3 parts of barium laurate; 5 parts of polytetrafluoroethylene; 13 parts of maleic anhydride grafted polyethylene; 25 parts of polyacrylate rubber 5 parts; 5 parts of octabromoether; 2 parts of masterbatch; 3 parts of 4,4'-bis(α,α-dimethylbenzyl)diphenylamine.

[0121] Manufacturing process:

[0122] Step 1. Preheat the SBS modified asphalt to 180°C, and preheat the polyethylene resin to 145°C at the same time, and then mix the two evenly.

[0123] Step 2: Add maleic anhydride-grafted polyethylene to the mixture obtained above, stir evenly, and knead in a vacuum kneader for 5 minutes at a kneading ...

Embodiment 3

[0138] formula:

[0139]A polyethylene composite pipe of the present invention is mainly composed of the following components in parts by weight: 120 parts of polyethylene resin; 20 parts of SBS modified asphalt; 1 part of light calcium carbonate; 1,2-dimethylimidazole 5 parts; 10 parts of nano-titanium dioxide / diatomite composite photocatalytic material; 4 parts of nano-zinc oxide; 6 parts of barium laurate; 5 parts of polytetrafluoroethylene; 7 parts of maleic anhydride grafted polyethylene; 15 parts of polyacrylate rubber 2 parts of octabromoether; 4 parts of masterbatch; 8 parts of 4,4'-bis(α,α-dimethylbenzyl)diphenylamine.

[0140] Manufacturing process:

[0141] Step 1. Preheat the SBS modified bitumen to 185°C, and preheat the polyethylene resin to 130°C at the same time, and then mix the two evenly.

[0142] Step 2: Add maleic anhydride-grafted polyethylene to the mixture obtained above, stir evenly, and knead in a vacuum kneader for 8 minutes. The kneading temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com