Low-temperature tolerance automobile belt anti-skidding agent and preparation method thereof

A technology of low temperature resistance and anti-slip agent, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of reduced belt anti-slip performance, reduced belt transmission efficiency, and belt slippage, so as to improve anti-slip ability and belt transmission rate , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A kind of anti-skid agent for automobile belts with low temperature resistance, prepared from the following raw materials in parts by weight: 70g purified water, 2.2g ammonium bifluoride, 2.2g citric acid, 0.1g sterilant dodecyl dimethyl benzyl ammonium chloride , 4g antifreeze propylene glycol, 0.1g brightening agent, wherein the brightening agent is configured with a ratio of 1:1 by methyl polysiloxane and KH560 silane coupling agent;

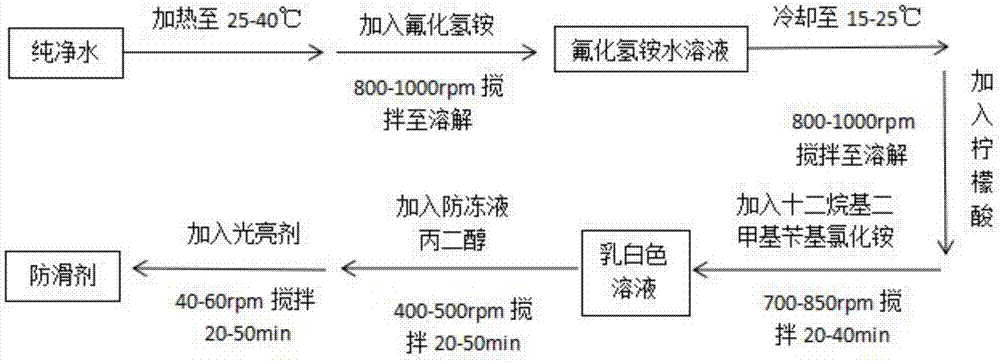

[0029] Described anti-skid agent is obtained by following preparation steps:

[0030] (1) Take the above-mentioned pure water by weight, heat it to 30°C in the reactor, add ammonium bifluoride to it, adjust the stirring speed of the reactor to 800-1000rpm, and stir evenly until the ammonium hydrogen fluoride is completely dissolved to obtain an aqueous solution of ammonium hydrogen fluoride ;

[0031] (2) Cool the ammonium bifluoride aqueous solution prepared in step 1 to 20° C., then add citric acid therein, and stir at a speed of 80...

Embodiment 2

[0036] A kind of anti-slip agent for automobile belts with low temperature resistance, prepared from the following raw materials in parts by weight: 68g purified water, 2.1g ammonium bifluoride, 2g citric acid, 0.08g sterilant dodecyl dimethyl benzyl ammonium chloride, 3g antifreeze propylene glycol, 0.08g brightening agent, wherein the brightening agent is configured by methyl polysiloxane and KH560 silane coupling agent in a ratio of 1:1;

[0037] Described anti-skid agent is obtained by following preparation steps:

[0038] (1) Take the pure water in the above parts by weight, heat it to 25°C in the reactor, add ammonium hydrogen fluoride to it, adjust the stirring speed of the reactor to 800-1000rpm, and stir evenly until the ammonium hydrogen fluoride is completely dissolved to obtain an aqueous solution of ammonium hydrogen fluoride ;

[0039] (2) Cool the ammonium bifluoride aqueous solution prepared in step 1 to 15° C., then add citric acid therein, and stir at a spee...

Embodiment 3

[0044] A kind of anti-slip agent for automobile belts with low temperature resistance, prepared from the following raw materials in parts by weight: 73g purified water, 2.5g ammonium bifluoride, 2.7g citric acid, 0.23g sterilant dodecyl dimethyl benzyl ammonium chloride , 6g antifreeze propylene glycol, 0.15g brightener, wherein the brightener is configured with a ratio of 1:1 by methyl polysiloxane and KH560 silane coupling agent;

[0045] Described anti-skid agent is obtained by following preparation steps:

[0046] (1) Take the pure water in the above parts by weight, heat it to 40°C in the reactor, add ammonium bifluoride to it, adjust the stirring speed of the reactor to 800-1000rpm, and stir evenly until the ammonium hydrogen fluoride is completely dissolved to obtain an aqueous solution of ammonium hydrogen fluoride ;

[0047] (2) Cool the ammonium bifluoride aqueous solution prepared in step 1 to 25° C., then add citric acid therein, and stir at a speed of 800-1000 rp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com