Polyethylene glycol oleic acid imidazoline corrosion inhibitor and preparation method thereof

A technology of polyethylene glycol oleic acid imidazoline and oleic acid imidazoline, applied in the field of polyethylene glycol oleic acid imidazoline corrosion inhibitor and its preparation, can solve poor stability, strong pungent smell, unsuitable for long-term storage, etc. problems, to achieve the effects of increasing polarity, improving water solubility, and facilitating large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

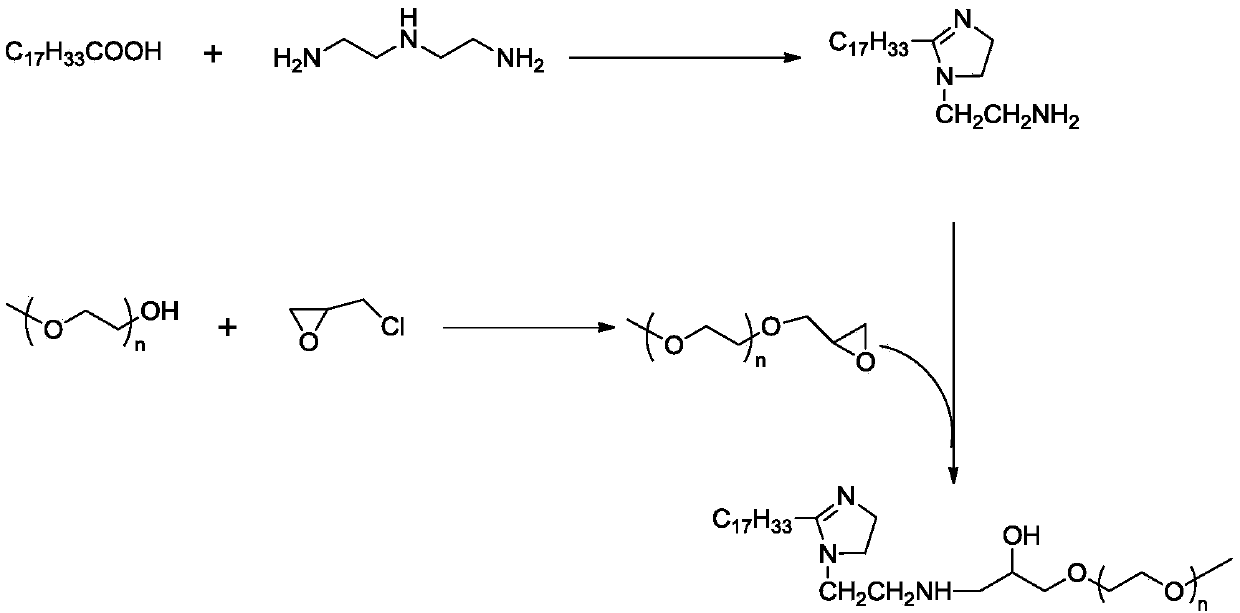

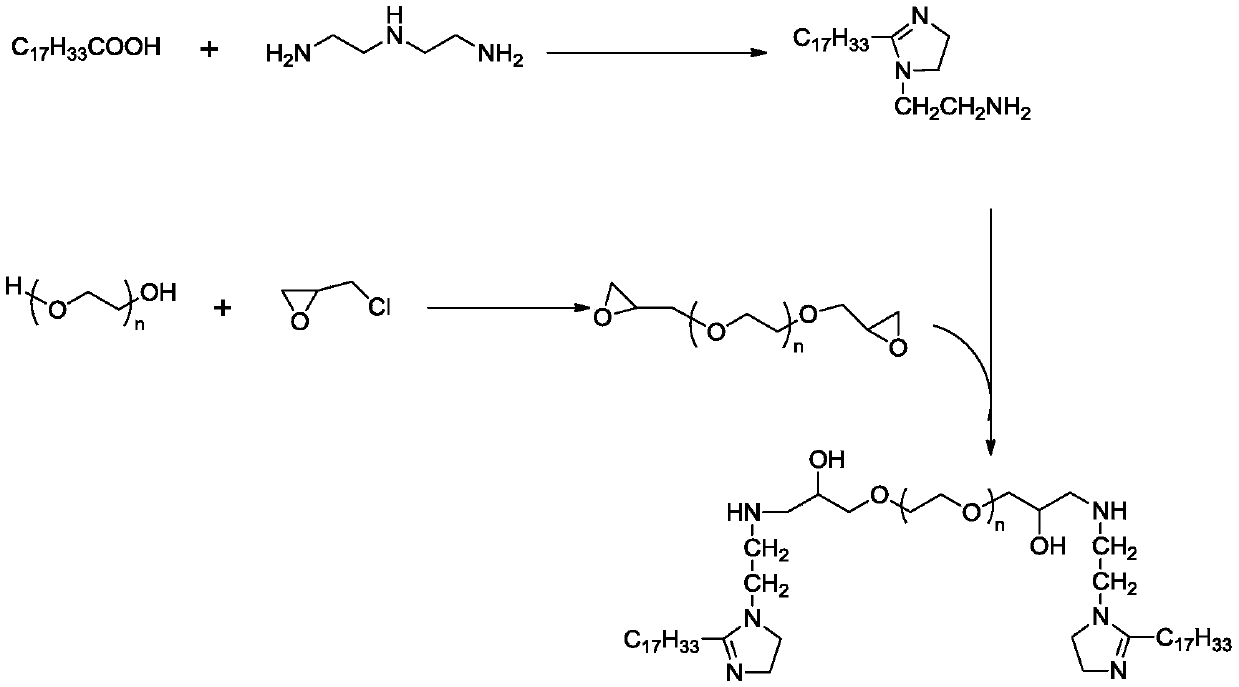

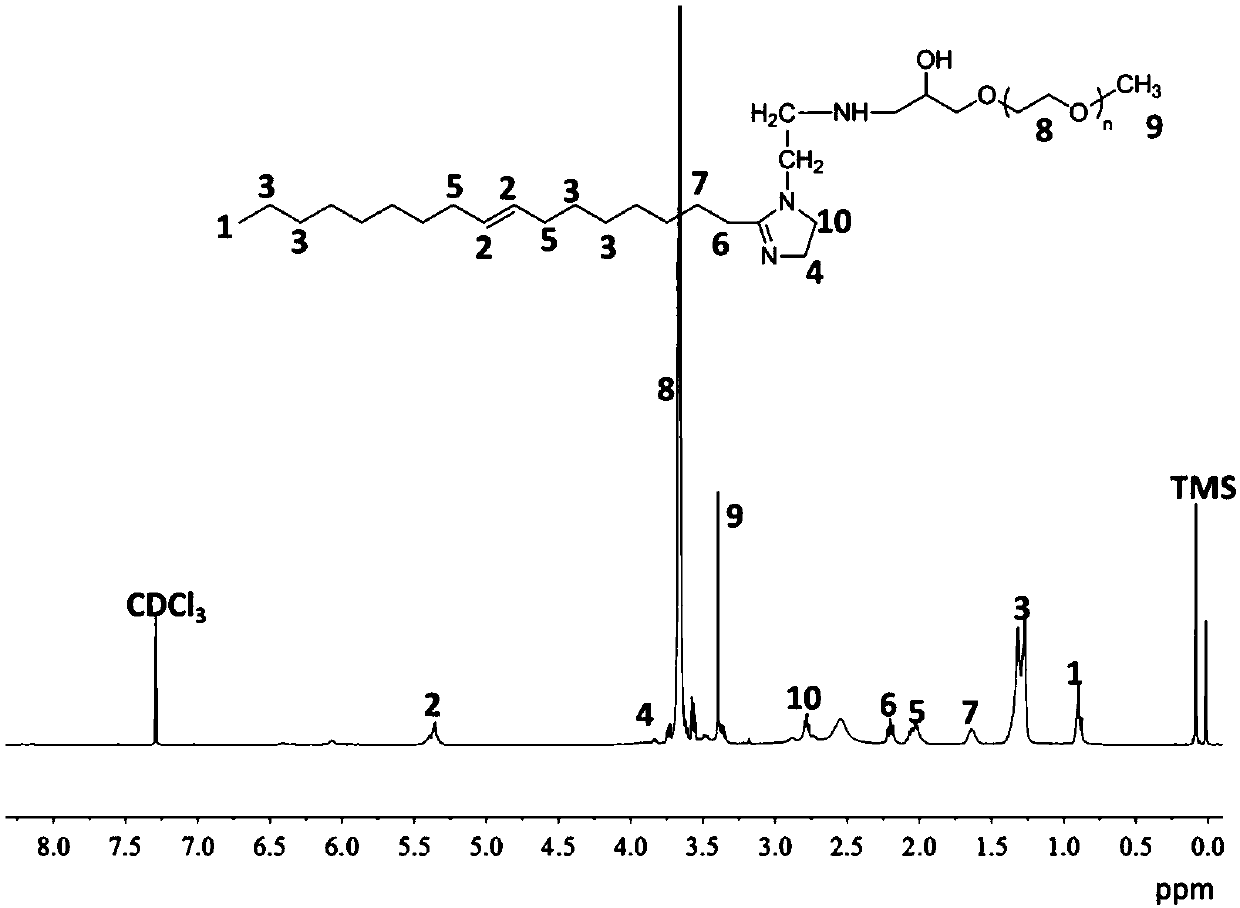

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 28.3 g of oleic acid (100 mmol), 12.38 g of diethylenetriamine (120 mmol) and 50 ml of water-carrying agent xylene into a round bottom flask equipped with a water separator and a condenser. Raise the temperature to 150°C and react for 3 hours. Continue to heat up to 210°C for 6 hours. After the reaction, excess xylene and unreacted diethylenetriamine were distilled off under reduced pressure at 150°C. Obtain oleic acid imidazoline (OIM);

[0030] (2) Mix 3 g of polyethylene glycol monomethyl ether (4 mmol) with a molecular weight of 750 g / mol and 70% sodium hydroxide (0.48 g, 12 mmol) in a round-bottomed flask, and heat up to 40° C. Alcohol monomethyl ether was melted, and 0.94 mL of epichlorohydrin (12 mmol) was added dropwise, and the reaction was continued at 40° C. for 0.5 hours after the dropwise addition. After the sodium hydroxide particles were removed by suction filtration, unreacted epichlorohydrin was removed by rotary evaporation. Epoxy-terminate...

Embodiment 2

[0033] (1) Add 28.3 g of oleic acid (100 mmol), 20.63 g of diethylenetriamine (200 mmol) and 50 ml of water-carrying agent xylene into a round bottom flask equipped with a water separator and a condenser. Raise the temperature to 150°C and react for 3 hours. Continue to heat up to 210°C for 10 hours of reaction. After the reaction, excess xylene and unreacted diethylenetriamine were distilled off under reduced pressure at 150°C. Obtain oleic acid imidazoline (OIM);

[0034] (2) Mix 3 g of polyethylene glycol monomethyl ether (3 mmol) with a molecular weight of 1000 g / mol and 90% sodium hydroxide (0.36 g, 9 mmol) in a round bottom flask, and heat up to 40° C. The alcohol monomethyl ether was melted, and 0.71 mL of epichlorohydrin (9 mmol) was added dropwise, and the reaction was continued at 40° C. for 1 hour after the dropwise addition. After the sodium hydroxide particles were removed by suction filtration, unreacted epichlorohydrin was removed by rotary evaporation. Epox...

Embodiment 3

[0037] (1) Add 28.3g of oleic acid (100mmol), 12.38g of diethylenetriamine (120mmol) and 50ml of water-carrying agent xylene into a round bottom flask equipped with a water separator and a condenser. Raise the temperature to 150°C and react for 3 hours. Continue to heat up to 210°C for 10 hours of reaction. After the reaction, excess xylene and unreacted diethylenetriamine were distilled off under reduced pressure at 150°C. Obtain oleic acid imidazoline (OIM);

[0038] (2) Mix 3.9 g of polyethylene glycol monomethyl ether (3 mmol) and 90% sodium hydroxide (0.48 g, 12 mmol) in a round-bottomed flask with a molecular weight of 1300 g / mol, and heat up to 45° C. Glycol monomethyl ether was melted, and 2.35 mL of epichlorohydrin (30 mmol) was added dropwise. After the dropwise addition, the reaction was continued at 40° C. for 1 hour. After the sodium hydroxide particles were removed by suction filtration, unreacted epichlorohydrin was removed by rotary evaporation. Epoxy-termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com