A low-phosphorus, environmentally friendly, corrosion and scale inhibitor applied to boilers and its preparation and use methods

A technology for corrosion and scale inhibition and boiler application in the fields of chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. Water eutrophication and other problems, to achieve the effect of excellent corrosion and scale inhibition performance, fast film forming speed, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Preparation of polyepoxysulfonic acid: Add 30-40 parts of 3-chloro-2-hydroxypropanesulfonic acid sodium and 25-35 parts of epoxy succinic acid into a pressure-bearing reactor, start stirring, and put the The temperature of the reaction kettle is increased to 70°C-120°C, and then 10-20 parts of sodium hydroxide with a mass concentration of 40% and 2-5 parts of alkaline earth metal (Ba) are added, and the reaction pH is controlled at 10-12, and the polymerization reaction time is 2 -4h to obtain polyepoxysulfonate carboxylate, and then react the obtained polyepoxysulfonate carboxylate with H-type cation exchange resin to obtain polyepoxysulfonate carboxylic acid. All the above are parts by mass.

[0026] Polyepoxysulfonic acid contains strong acidic groups, weak acidic groups and non-ionic groups at the same time, so that it has excellent scale inhibition and dispersion properties. Because it does not contain phosphorus and nitrogen, it is a green and environmentally fri...

Embodiment 1

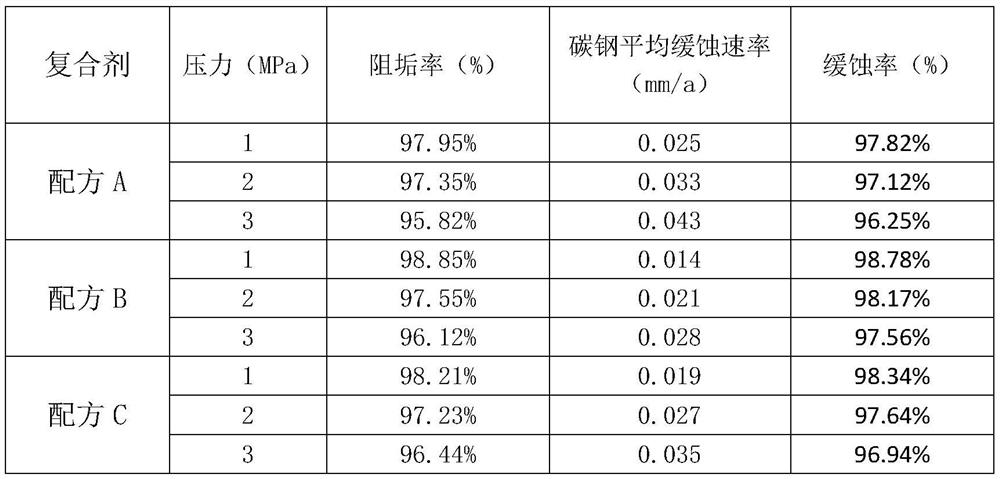

[0057] The above-mentioned formula A, formula B, and formula C were tested according to the "Dynamic Method for Evaluation of Performance of Boiler Water Treatment Chemicals" (HG / T3924-2007). The chemical dosing point is set at the output steam pipeline, the boiler supply water pipeline, and the boiler condensate water pipeline. It is added according to 5mg / L, and the specific dosing ratio is 1:2:2. The test pressure in the boiler is selected as 1MPa, 2MPa, and 3MPa for the test respectively, and the time is 12 days. The test water quality parameter is the total hardness (3 / 4Ca 2+ +1 / 4Mg 2+ ) 6mmol / L, alkalinity (HCO 3 - ) 2mmol / L, chloride ion (Cl - ) 10mmol / L, the results of scale and corrosion inhibition rate are shown in Table 1.

[0058] Table 1:

[0059]

[0060] It can be seen from Table 1 that formula A, formula B and formula C have better scale inhibition rate and corrosion inhibition rate, and formula B has the best performance.

Embodiment 2

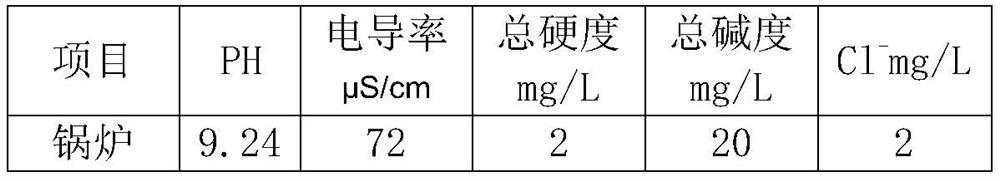

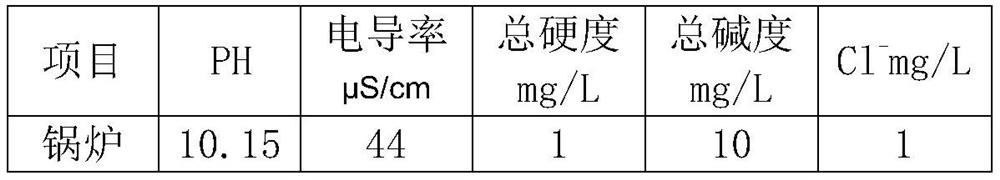

[0062] The water quality parameters of a boiler are shown in Table 2:

[0063] Table 2:

[0064]

[0065] Under the water quality conditions in Table 2, the boiler pressure was 2.4MPa, and the industrial simulation online test was carried out for 1 month. The corrosion and scale inhibitor of the invention was applied. Pipeline, dosing according to 2mg / L, the specific dosing ratio is 0.5:1.5:2. The test results show that the average corrosion inhibition rate of carbon steel is 0.026mm / a, the heating heat loss of the boiler is small, the scale inhibition performance is excellent, the boiler operation is stable, and the use effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com