A kind of composite corrosion inhibitor for cold water hollow copper wire in generator and its application

A composite corrosion inhibitor and generator technology, applied in the field of electrical engineering, can solve the problems of high investment cost and difficult operation and maintenance of water quality control methods, and achieve the effect of significant synergy, cheap raw materials, and guaranteed corrosion inhibition effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

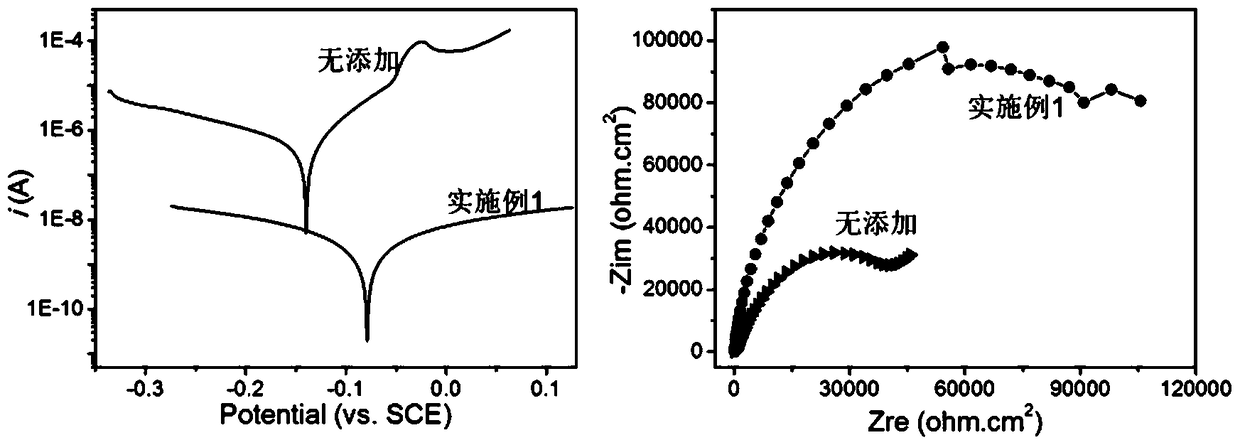

Embodiment 1

[0033] The generator internal cooling water hollow copper wire composite corrosion inhibitor is mixed with the following raw materials in parts by weight:

[0034]

Embodiment 2

[0036] The generator internal cooling water hollow copper wire composite corrosion inhibitor is mixed with the following raw materials in parts by weight:

[0037]

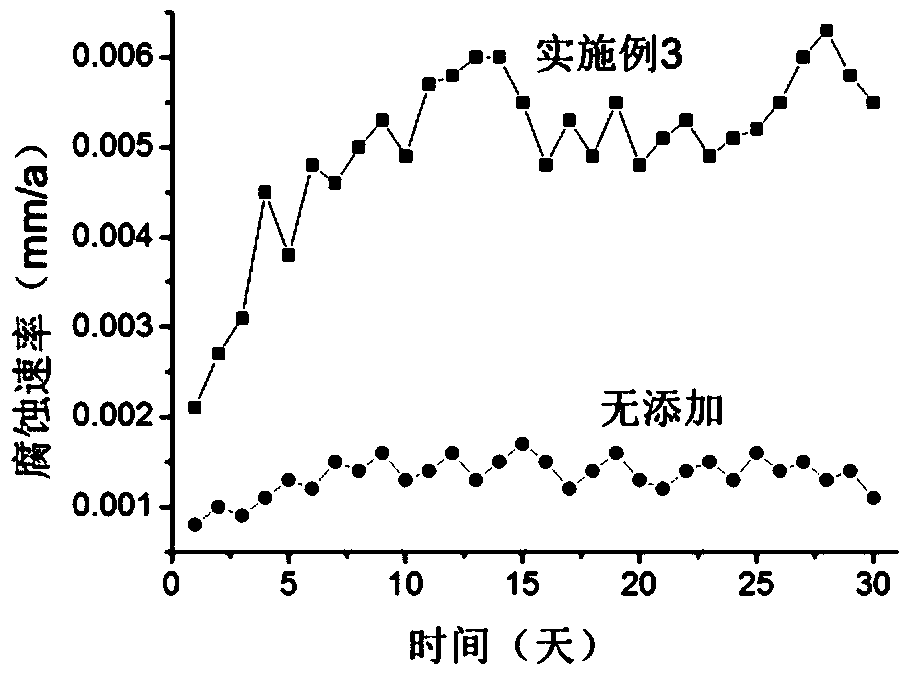

Embodiment 3

[0039] The generator internal cooling water hollow copper wire composite corrosion inhibitor is mixed with the following raw materials in parts by weight:

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com