AC/DC three-degree-of-freedom axial monobrid magnetic bearing for vehicle-mounted flywheel battery

A hybrid magnetic bearing and flywheel battery technology, applied in the direction of shafts and bearings, bearings, engine components, etc., can solve the problems of increasing the volume and quality of magnetic bearings, and achieve the effects of improving equipment efficiency, simplifying the magnetic circuit, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

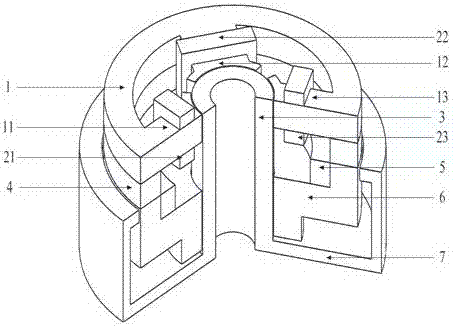

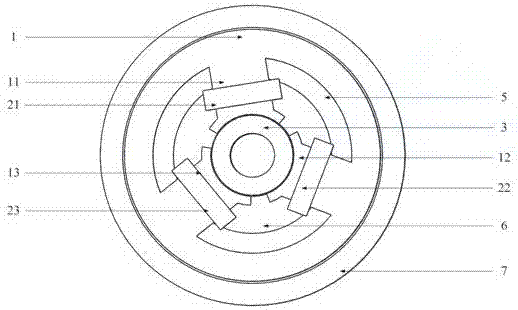

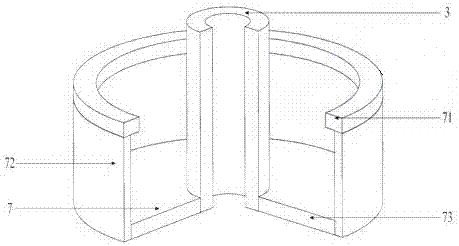

[0024] see figure 1 and figure 2 , in the middle of the present invention is the rotor 3, and outside the rotor 3, a radial stator 1, a permanent magnet 4, and a single-piece axial stator 6 are coaxially sleeved in sequence from top to bottom, and the axial stator 6 is covered with a tension disc 7, and the tension disc 7 is fixedly connected with the rotor 3 coaxially. The yoke of the radial stator 1 is a hollow cylinder, and the yoke of the radial stator 1 is uniformly arranged with three radial stator poles along the circumferential direction, which are respectively radial stator poles 11 , 12 , and 13 . The upper and lower end faces of the three radial stator poles 11 , 12 , and 13 are respectively flush with the upper and lower end faces of the yoke of the radial stator 1 . A radial control coil is wound on each radial stator pole, which are respectively radial control coils 21, 22, and 23. Three identical radial control coils are wound on the radial portion of the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com