Mining conveyer carrier roller fault monitoring, positioning and warning device

A fault monitoring and alarm device technology, applied in measuring devices, using wave/particle radiation, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of poor stability of the optical fiber monitoring system, and achieve the effect of overcoming poor stability and easy system control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following describes specific implementations of the content of the invention with reference to the drawings.

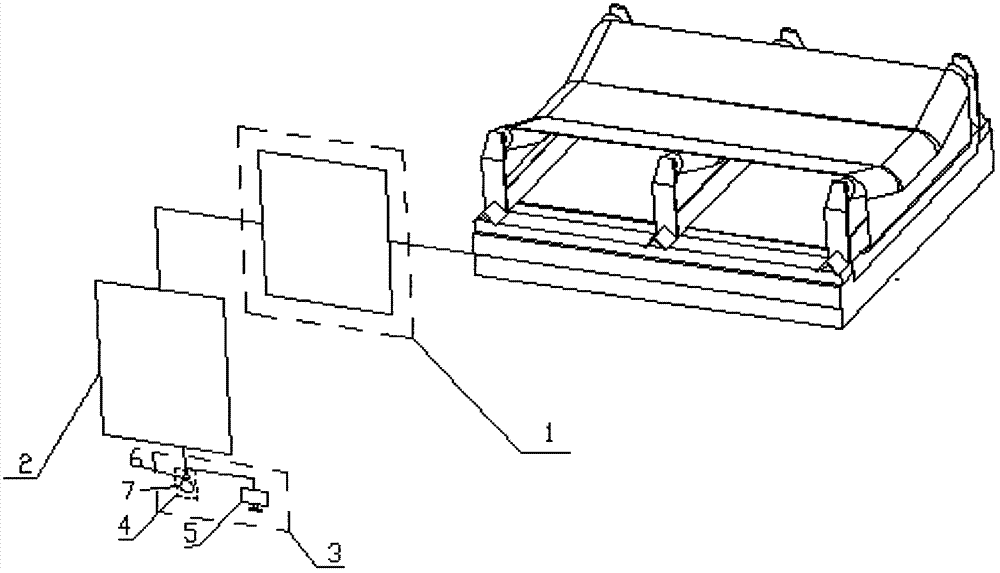

[0012] Such as figure 1 The shown a kind of mine conveyor roller failure monitoring and positioning and alarm device, including three parts: information acquisition module 1, information analysis and processing module 2, real-time monitoring module 3; information acquisition module 1 is located in the mining conveyor In the working environment, it is connected to the information analysis and processing module 2, and the information analysis and processing module is connected to the real-time monitoring module 3. The information acquisition module 1 includes sensing fiber, drive power, semiconductor laser, coupler, amplifier, photoelectric converter, and signal acquisition card ; Use the sensing optical fiber laid along both sides of the roller (conveyor belt) for sensing, capture the two-dimensional distribution of vibration information along the time and space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com