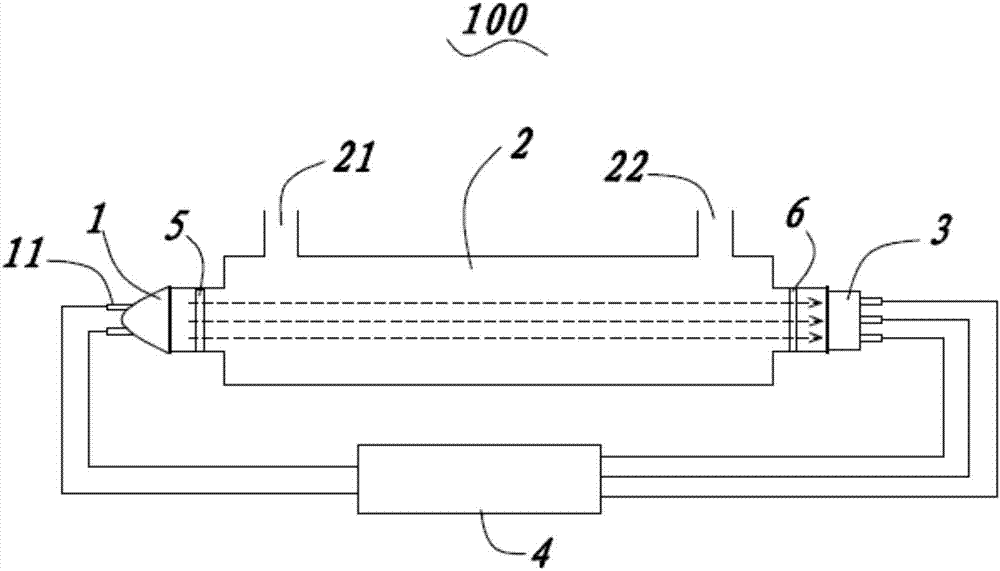

Non-chromatic-dispersion infrared gas sensor capable of lowering detection lower limit and detection method thereof

A non-dispersive infrared and gas sensor technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems that the length of the optical path cannot be increased infinitely, the detection accuracy is not high, and the cost of the optical path is increased, so as to reduce the standard deviation stdev, The effect of increasing the number of collections and reducing the lower limit of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

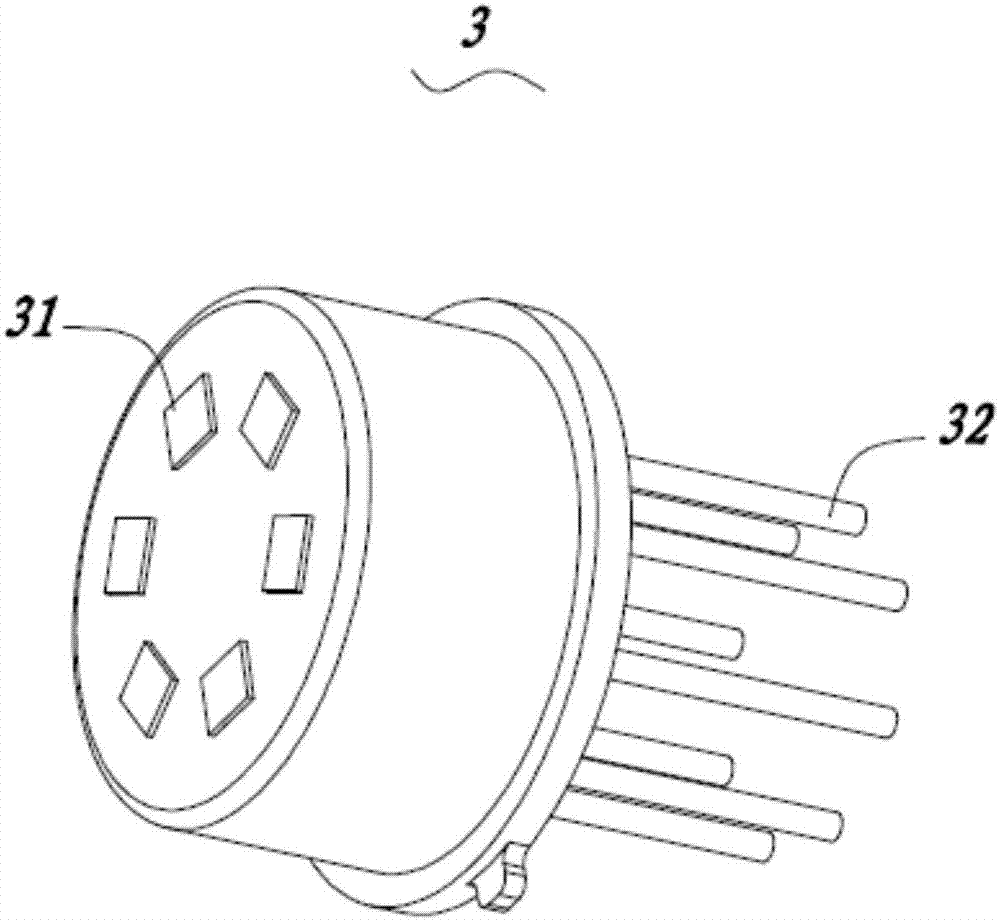

[0044] The number of channels 31 of the infrared detector 3 is set to four: one reference channel, configured with a 3.9 μm filter; three for detecting CO 2 The gas measurement channel is equipped with a 4.26μm filter. The sampling period (scanning rate) of each channel 31 is consistent, which can reduce the CO in the gas to be measured 2 lower limit of detection.

Embodiment 2

[0046] The number of channels 31 of the infrared detector 3 is set to six: one reference channel, configured with a 3.9 μm filter; five for detecting CO 2 The gas measurement channel is equipped with a 4.26μm filter. The sampling period (scanning rate) of each channel 31 is consistent, which can further effectively reduce the CO in the gas to be measured 2 lower limit of detection.

Embodiment 3

[0048] The number of channels 31 of the infrared detector 3 is set to six: one reference channel, configured with a 3.9 μm filter; three for detecting CO 2 The gas measurement channel is configured with a 4.26μm filter; two are used to detect CH 4 The gas measurement channel is equipped with a 3.3μm filter. The sampling period (scanning rate) of each channel 31 is consistent, which can reduce the CO in the gas to be measured 2 、CH 4 lower limit of detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com