A kind of chemical warfare agent sensor and preparation method thereof

A chemical warfare agent and sensor technology, applied in the field of sensors, can solve the problems of unsatisfactory large-scale, multi-point delivery, expensive instruments, heavy weight, etc., to achieve easy mass production and large-scale delivery, and improve linearity and repeatability , High miniaturization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

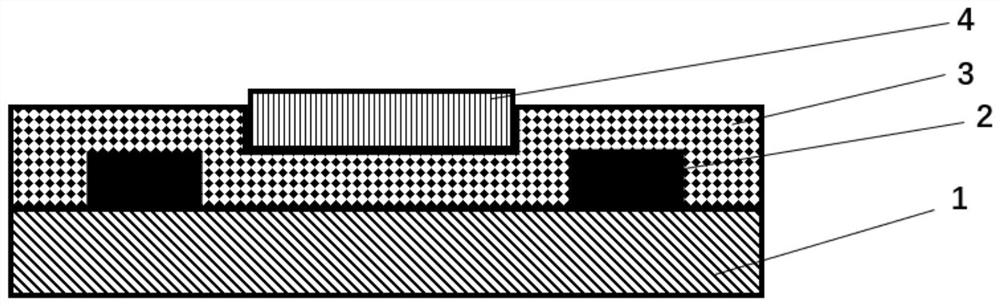

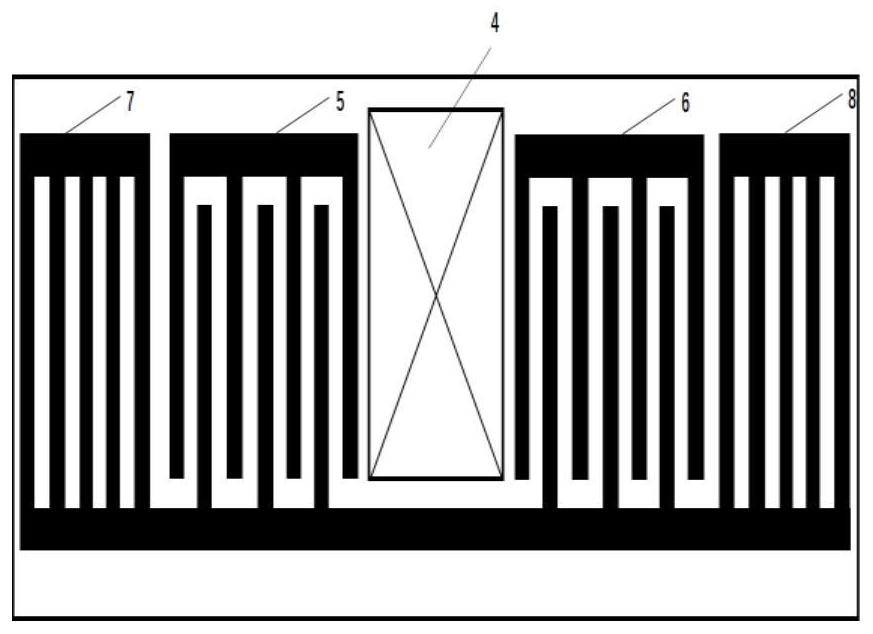

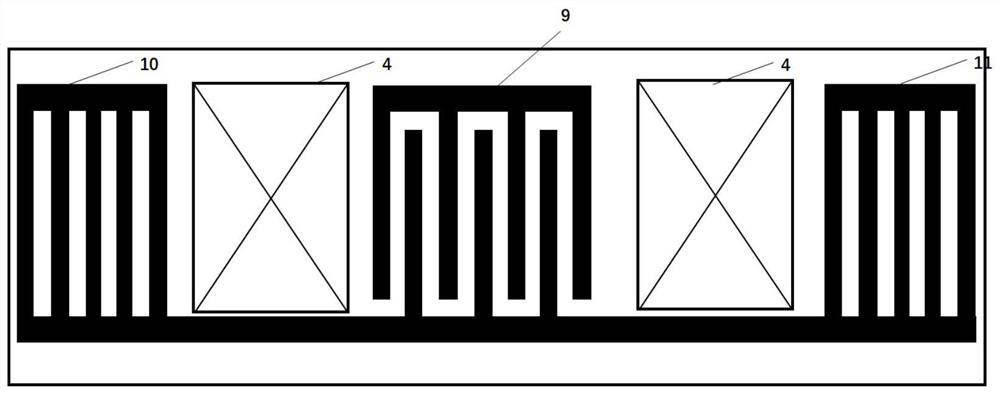

Method used

Image

Examples

Embodiment 1

[0045] 1) Pretreatment of the piezoelectric substrate layer: take a 500 μm thick ST-quartz piezoelectric substrate and cut it into a geometric size of 35 cm×10 cm. Ultrasonic cleaning with anhydrous ethanol for 20 minutes; ultrasonic cleaning in dilute ammonia water for 10 minutes at a cleaning temperature of 80°C; ultrasonic cleaning in dilute hydrochloric acid for 10 minutes at a cleaning temperature of 80°C, and finally the ST-quartz piezoelectric substrate in deionized water for 20 minutes , blow dry with nitrogen gas for later use. Described dilute ammonia water is that 27wt% ammonia water and deionized water are ammonia water by volume fraction: deionized water=1:50 is formulated; Described dilute hydrochloric acid solution is 37wt% hydrochloric acid and deionized water is hydrochloric acid by volume fraction: Deionized water = 1:8 prepared.

[0046] 2) Preparation of interdigitated electrodes and / or reflective grid layer: use a vacuum coating machine to vapor-deposit a...

Embodiment 2

[0053] 1) Pretreatment of the piezoelectric substrate layer: take a 300 μm thick 128° Y-X piezoelectric substrate and cut it into a geometric size of 25 cm×10 cm. Ultrasonic cleaning with anhydrous ethanol for 20 minutes; ultrasonic cleaning in dilute ammonia water for 5 minutes at a cleaning temperature of 80°C; ultrasonic cleaning in dilute hydrochloric acid for 5 minutes at a cleaning temperature of 80°C, and finally cleaning the 128°Y-X piezoelectric substrate in deionized water for 20 minutes , blow dry with nitrogen gas for later use. Described dilute ammonia water is that 27wt% ammonia water and deionized water are ammonia water by volume fraction: deionized water=1:50 is formulated; Described dilute hydrochloric acid solution is 37wt% hydrochloric acid and deionized water is hydrochloric acid by volume fraction: Deionized water = 1:8 prepared.

[0054] 2) Preparation of interdigitated electrodes and / or reflective gate layer: Deposit a layer of Cu film with a thickness...

Embodiment 3

[0060] 1) Pretreatment of the piezoelectric substrate layer: take a 550 μm thick PVDF-TrFE piezoelectric substrate and cut it into a geometric size of 50 cm×40 cm. Ultrasonic cleaning with absolute ethanol for 30 minutes; ultrasonic cleaning in dilute ammonia water for 3 minutes at a cleaning temperature of 50°C; ultrasonic cleaning in dilute hydrochloric acid for 3 minutes at a cleaning temperature of 50°C, and finally the PVDF-TrFE piezoelectric substrate was cleaned in deionized water for 20 minutes , blow dry with nitrogen gas for later use. Described dilute ammonia water is that 27wt% ammonia water and deionized water are ammonia water by volume fraction: deionized water=1:50 is formulated; Described dilute hydrochloric acid solution is 37wt% hydrochloric acid and deionized water is hydrochloric acid by volume fraction: Deionized water = 1:8 prepared.

[0061] 2) Preparation of interdigitated electrodes and / or reflective grid layer: use screen printing technology to prin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com