Quantitative detection method for low-concentration urea in ultrapure water

A quantitative detection method and low-concentration technology, applied in the field of quantitative detection of low-concentration urea, can solve problems such as failure to meet urea detection requirements, and achieve the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

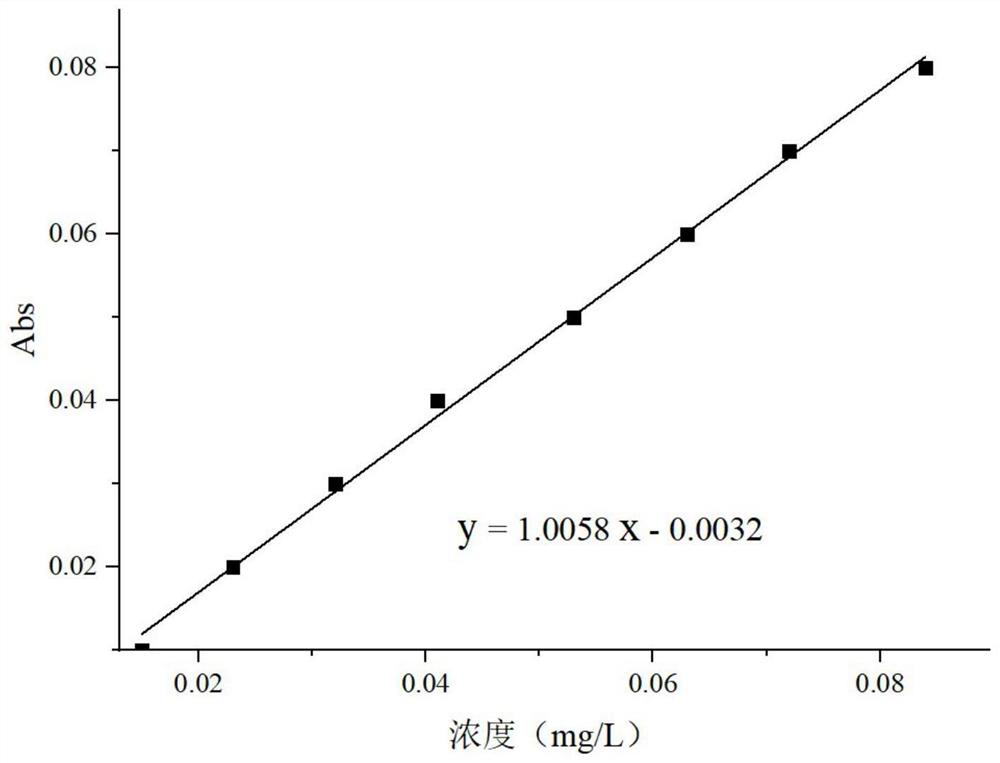

Image

Examples

Embodiment 1

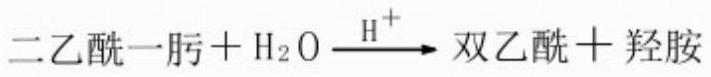

[0025] The quantitative detection method of low-concentration urea in ultrapure water of the present invention specifically comprises the following steps:

[0026] Step (1), take 250mL of the initial water sample and put it into a PTFE plastic bottle, tighten the bottle cap, then pre-freeze it in a -80°C freezer for 24 hours, take it out, unscrew the bottle cap, and put the PTFE plastic bottle. The bottle was placed in a vacuum freeze dryer and dried for 24 hours. After drying, the polytetrafluoroethylene plastic bottle was taken out and placed at room temperature until the ice cubes in it were completely dissolved; at this time, water (same as the initial water sample) was added to the liquid by constant volume. water with the same composition), until the liquid volume is 1 / 10 of the initial water sample volume (ie 25mL); the vacuum degree of the dryer is 0.05MPa, and the temperature is -50℃; the urea concentration in the initial water sample is 0.3ug / L; the vacuum After free...

Embodiment 2

[0071] The quantitative detection method of low-concentration urea in ultrapure water of the present invention specifically comprises the following steps:

[0072] Step (1), take 250mL of the initial water sample and put it into a PTFE plastic bottle, tighten the bottle cap, then pre-freeze it in a -80°C freezer for 24 hours, take it out, unscrew the bottle cap, and put the PTFE plastic The bottle was placed in a vacuum freeze dryer and dried for 24 hours. After drying, the polytetrafluoroethylene plastic bottle was taken out and placed at room temperature until the ice cubes in it were completely dissolved; at this time, water (same as the initial water sample) was added to the liquid by constant volume. water with the same composition), until the liquid volume is 1 / 10 of the initial water sample volume (ie 25mL); the vacuum degree of the dryer is 0.05MPa, and the temperature is -50℃; the urea concentration in the initial water sample is 0.4ug / L; the vacuum After freeze-dryin...

Embodiment 3

[0080] The quantitative detection method of low-concentration urea in ultrapure water of the present invention specifically comprises the following steps:

[0081] Step (1), take 250mL of the initial water sample and put it into a PTFE plastic bottle, tighten the bottle cap, then pre-freeze it in a -80°C freezer for 24 hours, take it out, unscrew the bottle cap, and put the PTFE plastic The bottle was placed in a vacuum freeze dryer and dried for 24 hours. After drying, the polytetrafluoroethylene plastic bottle was taken out and placed at room temperature until the ice cubes in it were completely dissolved; at this time, water (same as the initial water sample) was added to the liquid by constant volume. water with the same composition), until the liquid volume is 1 / 10 of the initial water sample volume (ie 25mL); the vacuum degree of the dryer is 0.05MPa, and the temperature is -50℃; the urea concentration in the initial water sample is 0.5ug / L; the vacuum After freeze-dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com