Detection and Characterization Methods of Intergranular Fracture and Transgranular Fracture of WC Grain in WC-Co Alloy

A technology of transgranular fracture and intergranular fracture, applied in the direction of testing material strength by applying a stable bending force, measuring device, and testing material strength by using a single impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: 5 cemented carbide samples with grade A and an average grain size of 1.6um were used to test the flexural strength, and the test results of each test strip were recorded according to serial numbers 1-5, as shown in Table 1.

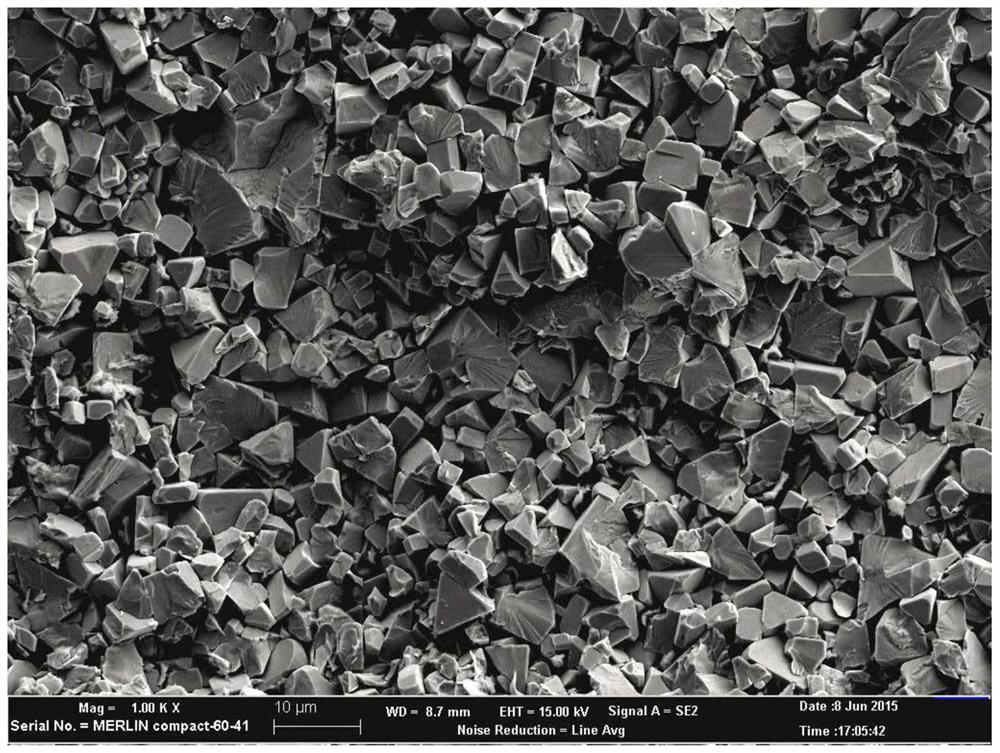

[0034] Then carry out the cohesive phase Co removal treatment on the fractured surface of the sample, that is, put the fractured sample into an HCl solution with a concentration of 5% to 37%, and corrode for 1 to 10 minutes until the cohesive phase is removed. The specific corrosion time is judged by the fact that the bonding phase Co on the fracture surface is completely removed, such as figure 1 Typical morphology of the cemented carbide fracture surface after removal of the binder phase Co. The morphology of the fracture surface of this sample after removing Co is as follows: Figure 4 shown.

[0035] Then the above samples were cleaned and dried, that is, the fractured samples were first rinsed with distilled water, then cleaned wi...

Embodiment 2

[0043] Example 2: 5 cemented carbide samples with brand B and an average grain size of 3.2um were used to test the flexural strength, and the test results of each test strip were recorded according to the serial numbers 1-5, see Table 2.

[0044] Then, the binder phase Co removal treatment on the fracture surface of the sample is carried out, that is, the fracture sample is put into FeCl 3 In an etching solution in which the mass ratio of the solid to the HCl solution with a concentration of 5% to 37% is 1:2, etch for 1 to 10 minutes until the bonding phase is removed. The specific corrosion time is judged by the fact that the bonding phase Co on the fracture surface is completely removed, such as figure 1 Typical morphology of the cemented carbide fracture surface after removal of the binder phase Co. The fracture morphology of the fracture surface of this sample after removal of Co is as follows: Figure 6 shown.

[0045] Then the above samples were cleaned and dried, tha...

Embodiment 3

[0053] Example 3: 5 cemented carbide samples with the grade C and an average grain size of 3.2um were used to test the impact toughness, and the test results of each test strip were recorded according to the serial numbers 1-5, as shown in Table 3.

[0054] Then, the cohesive phase Co removal treatment on the fractured surface of the sample is performed, that is, the fractured sample is put into a 5% to 37% HCl solution, and corroded for 1 to 10 minutes until the cohesive phase is removed. The specific corrosion time is judged by the fact that the bonding phase Co on the fracture surface is completely removed, such as figure 1 Typical morphology of the cemented carbide fracture surface after removal of the binder phase Co. The fracture morphology of the fracture surface of this sample after removal of Co is as follows: Figure 8 shown.

[0055] Then the above samples were cleaned and dried, that is, the fractured samples were first rinsed with distilled water, then cleaned w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com