Monitoring method for corrosive damage of hole edge of aluminum alloy porous structure

A technology for porous structure and damage monitoring, which can be used in measurement devices, analysis of solids using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves. It can solve problems such as difficult real-time and effective monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] A method for monitoring corrosion damage of aluminum alloy structures based on an algebraic iterative reconstruction algorithm of the present invention, see Figure 8 As shown, its specific implementation steps are as follows:

[0063] step one:

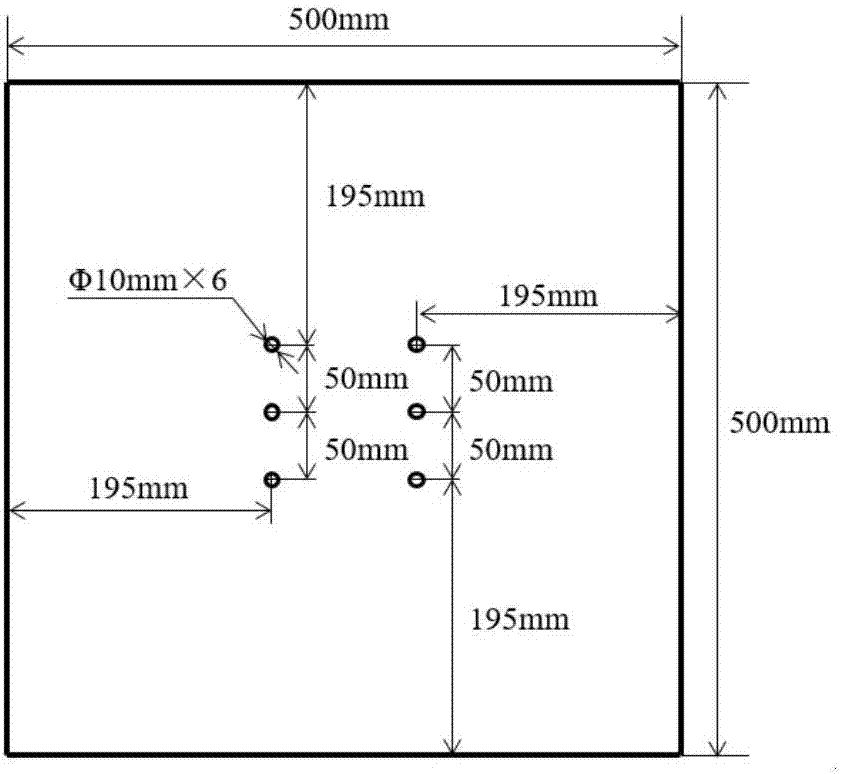

[0064] This patent selects material Al-2024-T3, and its density, Young's modulus and Poisson's ratio are respectively 2.78g / cm3, 73.1GPa, 0.33. Its size is designed to be 500mm*500mm*2mm. There are 6 holes with a diameter of 10mm in the middle of the aluminum alloy plate, the size of which is as follows figure 2 shown.

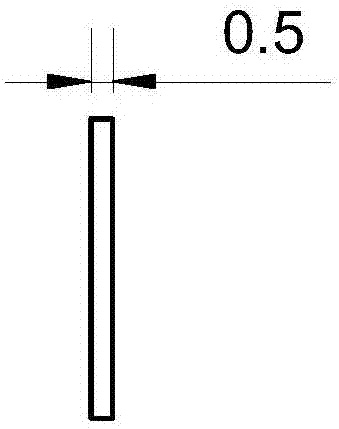

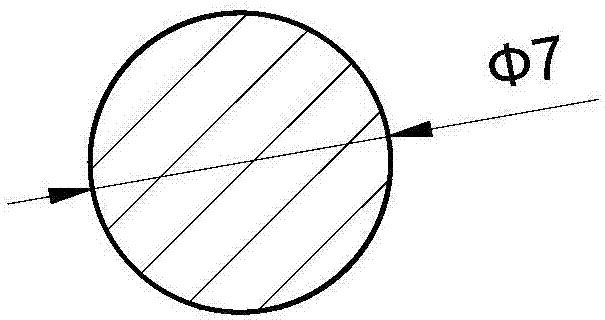

[0065] This patent selects the piezoelectric sensor of American Steminc Company for use. The size and appearance of the piezoelectric sensor are shown in Figure 1.

[0066] In this patent, the rectangular array is selected from linear array, rectangular array, circular array and parallel array according to the aluminum alloy material to be tested and the geometric characteristics of the piezoelectric sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com