Two-sided heat dissipation power module of laminated substrates

A double-sided heat dissipation, power module technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of hindering power density, chip overvoltage breakdown, parasitic inductance difficulty, etc., to reduce the area of the commutation loop, The effect of increasing the area of the metal layer and reducing the lead resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

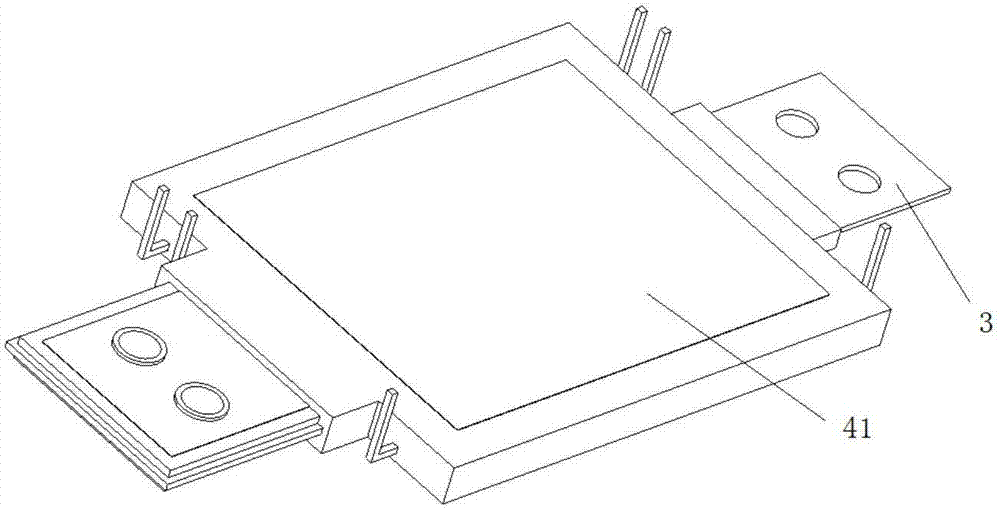

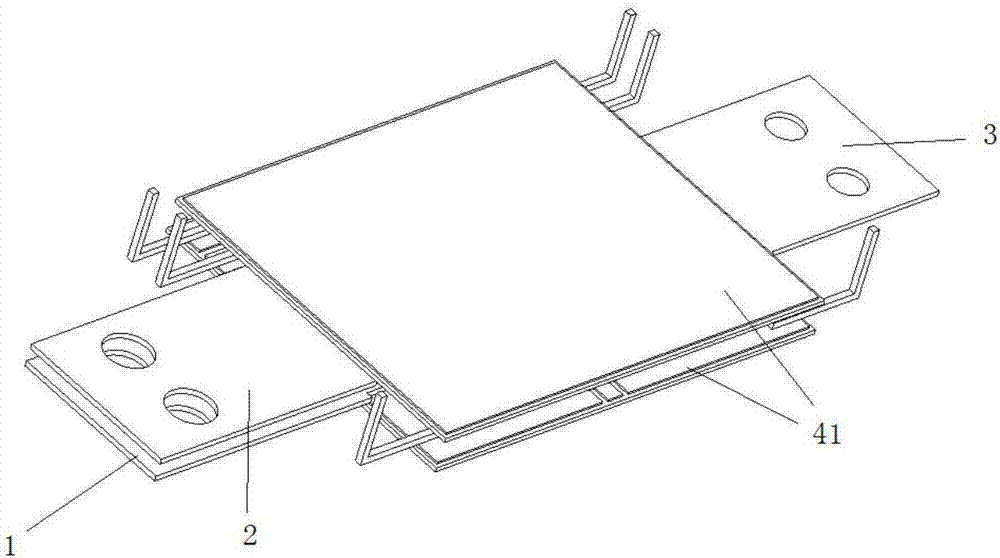

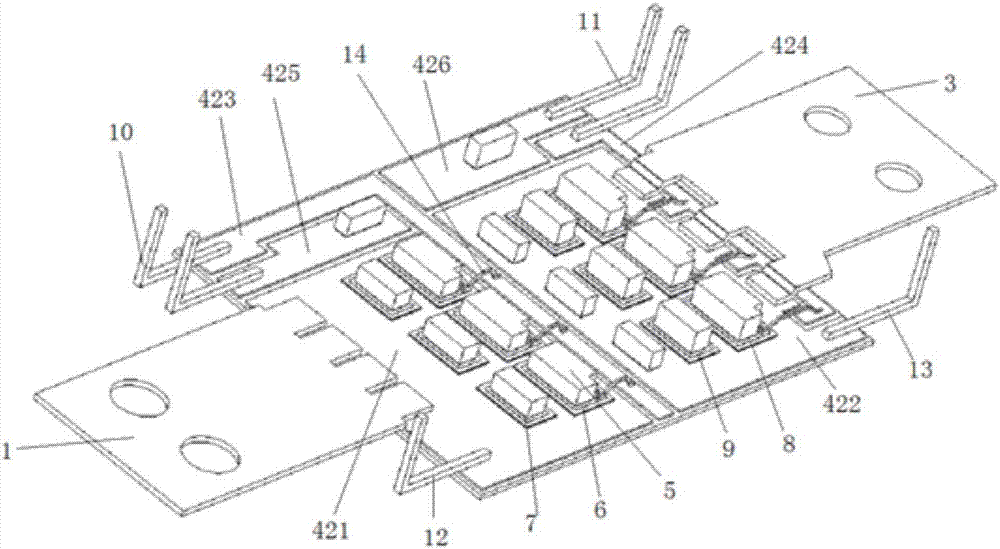

[0030] Such as figure 1 As shown, a double-sided heat dissipation power module with a laminated substrate includes a positive power terminal 1, a negative power terminal 2, and an output power terminal 3. The positive power terminal 1 and the negative power terminal 2 are each connected to an outer metal insulating substrate 41, as shown in FIG. It can be seen that the outer metal insulating substrate 41 at the top is connected to the negative power terminal 2 , and the outer metal insulating substrate 41 at the bottom is connected to the positive power terminal 1 .

[0031] Two outer metal insulating substrates 41 are stacked, and a chip is sintered on the outer metal insulating substrate 41 connected to the positive power terminal 1; the middle metal insulating substrate 42 is arranged on the outer metal insulating substrate 41 connected to the negative power terminal 2; The metal block 5 is sintered with the metal insulating substrate opposite to it.

[0032] The positive ...

Embodiment 2

[0044] Such as Figure 9 , Figure 10 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that in this embodiment, the outer metal insulating substrate 41 connected to the positive power terminal 1 is provided with an intermediate metal insulating substrate 42 and the intermediate metal insulating substrate 42 There are also chips sintered on it, the chips set on the outer metal insulating substrate 41 connected to the positive power terminal 1 are the upper half-bridge switch chip 6 and the upper half-bridge diode chip 7, and the chips set on the middle metal insulating substrate 42 are the lower half-bridge A switch chip 8 and a lower half-bridge diode chip 9 . The specific configuration of the metal layers is shown in the figure, and the specific names and connection methods of each metal layer can be set according to the routine by those skilled in the art with reference to Embodiment 1, and will not be repeated here...

Embodiment 3

[0046] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that the intermediate metal insulating substrate 42 in this embodiment includes an insulating layer and two metal layers respectively arranged on both sides of the insulating layer, and one metal layer is insulated from the outer metal. The substrate 41 is adjacent, and chips or metal blocks are sintered on another metal layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com