Double-surface heat-dissipation and high-reliability power module

A double-sided heat dissipation and power module technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems that the liner area cannot be further reduced, the current path loss increases, and the power module is large in size, so as to reduce the solder layer Risk of cracking, reduction of thermal resistance, effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

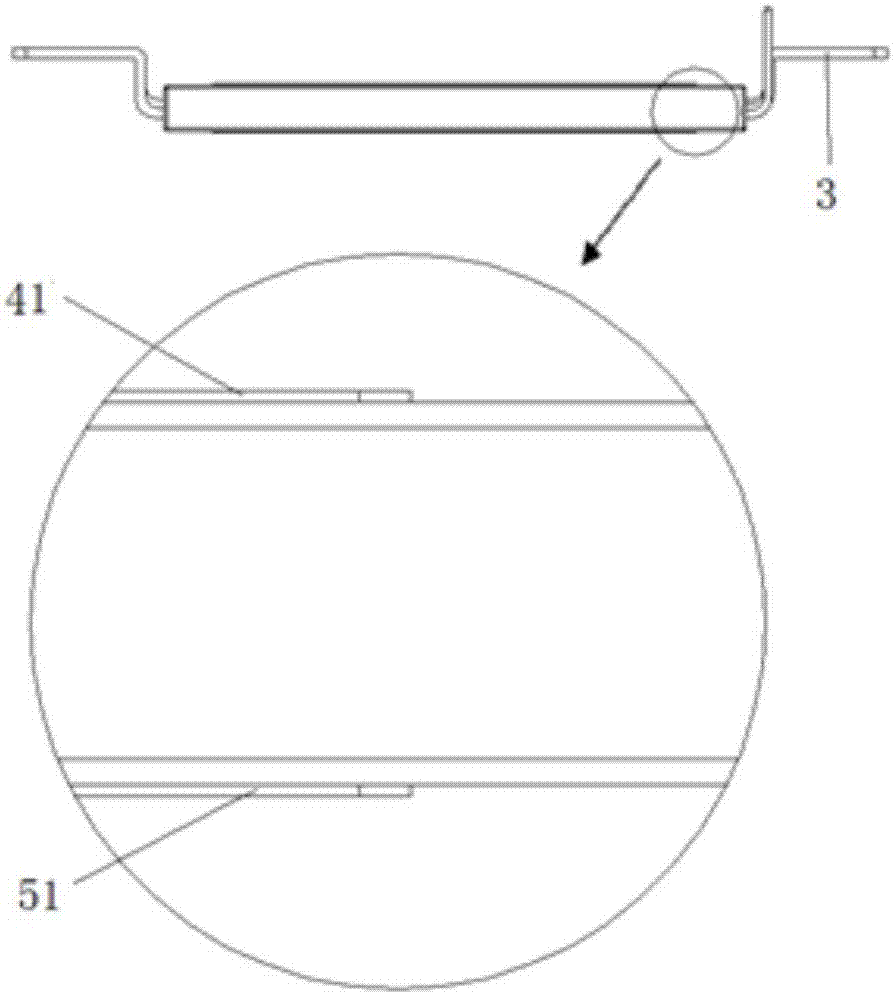

[0031] The technical solution will be described in detail below through embodiments and in conjunction with the accompanying drawings.

[0032] In the present invention, the switch chip and the freewheeling diode chip of the opposite bridge arm are stacked to make the path of the commutation circuit the shortest, thereby greatly reducing the parasitic inductance of the circuit; the surface of the chip is mechanically and electrically connected through a metal material with a matching thermal expansion coefficient, and the power is improved. module reliability.

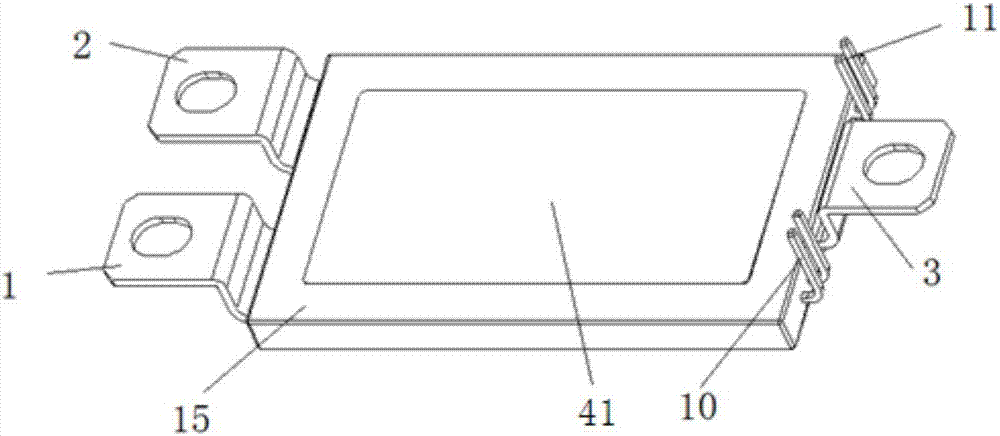

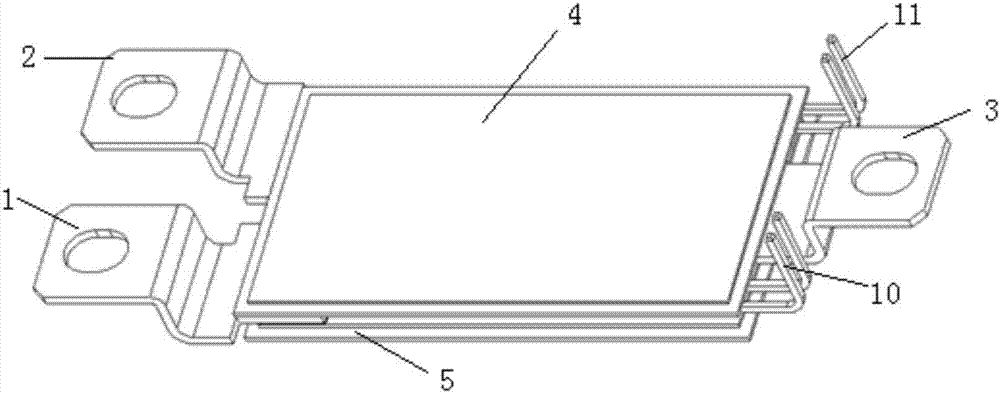

[0033] Such as figure 1 As shown, a high-reliability power module with double-sided heat dissipation includes a positive power terminal 1, a negative power terminal 2, an output power terminal 3, a bottom metal insulating substrate 5, a top metal insulating substrate 4, and a plastic casing 15 for encapsulation.

[0034] In this embodiment, the metal insulating substrates used in the bottom metal insulating substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com