Organic light emitting diode display panel and manufacturing method thereof, and display device

A technology of light-emitting diodes and display panels, which is applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, and electric solid-state devices. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

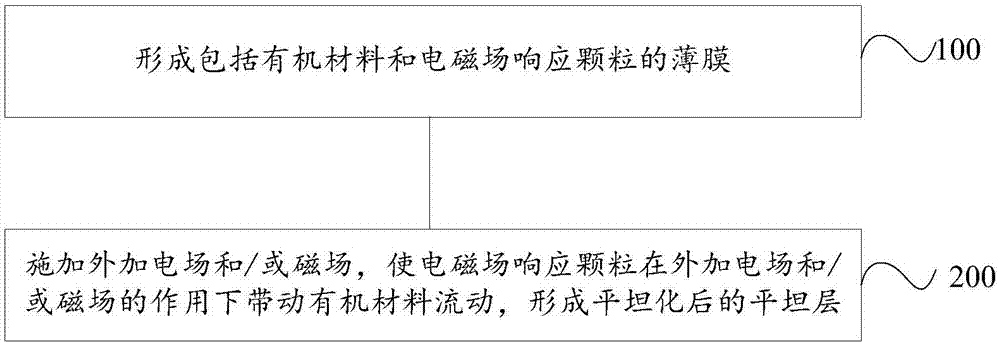

[0044] figure 1 The flow chart of the OLED display panel manufacturing method provided by Embodiment 1 of the present invention, as shown in figure 1 As shown, the OLED display panel manufacturing method provided by Embodiment 1 of the present invention specifically includes the following steps:

[0045] Step 100, forming a thin film including organic materials and electromagnetic field responsive particles.

[0046] Among them, the organic material is polymethyl methacrylate, polyimide, silicone material, etc., and the electromagnetic field responsive particle is a particle that can respond to both an electric field and a magnetic field, and has a nanometer-scale diameter. It should be noted that the response to an electric field Specifically, it means that particles can move under the action of an electric field. Similarly, responding to a magnetic field means that particles can move under the action of a magnetic field.

[0047] Specifically, the electric field responsive...

Embodiment 2

[0074] Based on the above inventive concept, Embodiment 2 of the present invention provides another OLED display panel manufacturing method, which is different from the OLED display panel manufacturing method provided in Embodiment 1 of the present invention in that:

[0075] Step 100 specifically includes: coating a thin film comprising an organic material on the thin film transistor; and doping the organic material with electromagnetic field responsive particles.

[0076] Specifically, the thin film transistor in this embodiment has a top-gate structure, which includes: an active layer, a gate insulating layer disposed on the active layer and covering the entire substrate, a gate electrode disposed on the gate insulating layer, and a gate electrode disposed on the gate An interlayer insulating layer on the electrodes and covering the entire substrate, and a source-drain electrode arranged on the interlayer insulating layer and electrically connected to the active layer.

[0...

Embodiment 3

[0101] Based on the inventive concepts of the foregoing embodiments, Figure 4 A schematic structural diagram of the OLED display panel provided in Embodiment 3 of the present invention, as shown in Figure 4 As shown, the OLED display panel provided by the embodiment of the present invention is manufactured by using the OLED display panel manufacturing method of Embodiment 1 or Embodiment 2, and its realization principle and effect are similar, and will not be repeated here.

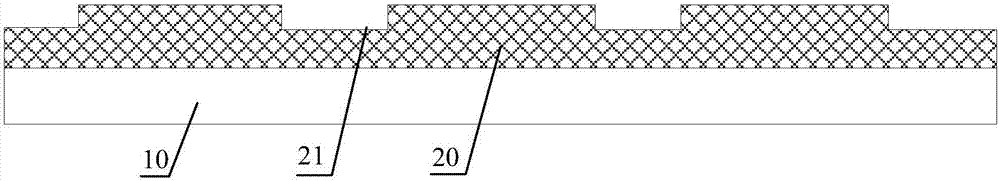

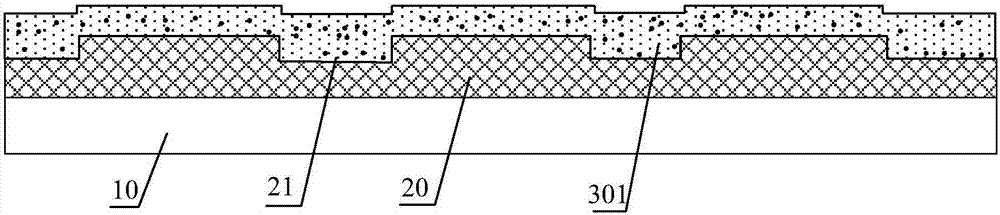

[0102] Specifically, the OLED display panel provided in this embodiment includes: a substrate 10 , a thin film transistor 20 with a plurality of recessed regions 21 disposed on the upper surface of the substrate 10 , and a flat layer 30 disposed on the side of the thin film transistor 20 away from the substrate 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com