Lithium iron phosphate trace mixed ternary cathode material cathode plate, preparation method thereof and power lithium ion battery

A positive electrode material, lithium iron phosphate technology, applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve problems affecting battery power performance, uneven surface coating thickness, poor surface coating effect, etc. Achieve the effect of reducing the risk of loss of control, improving safety performance, and avoiding inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

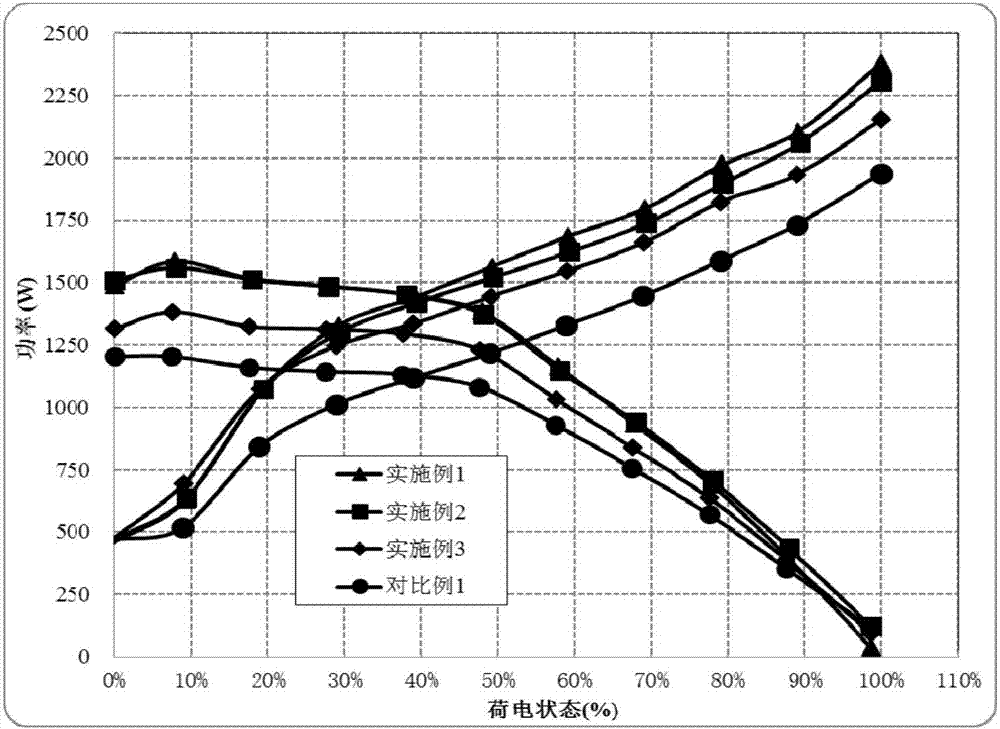

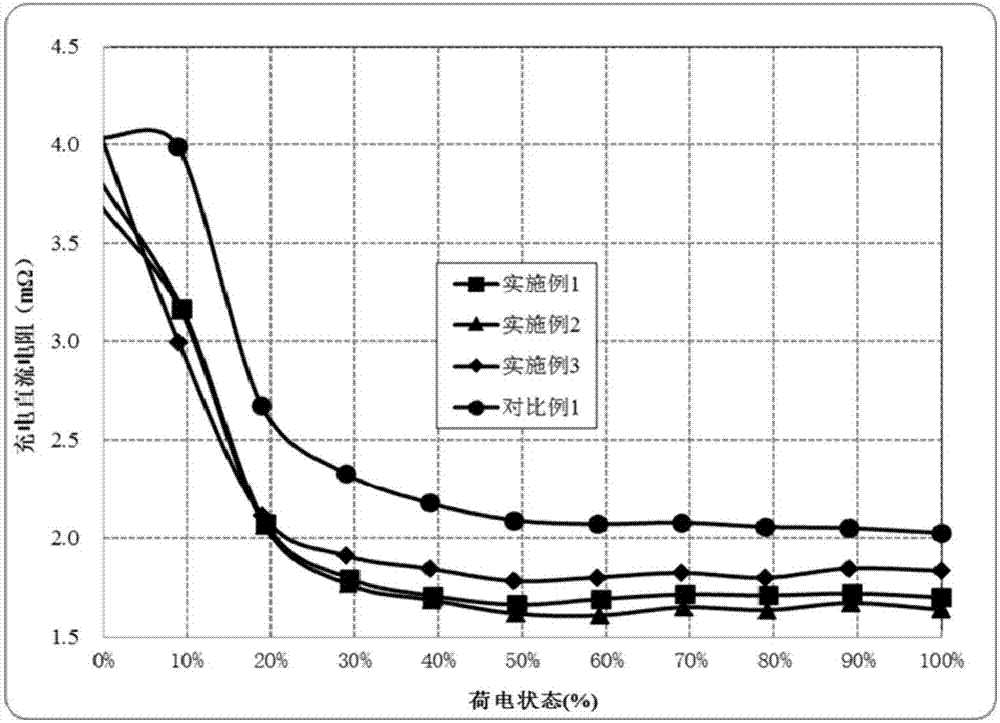

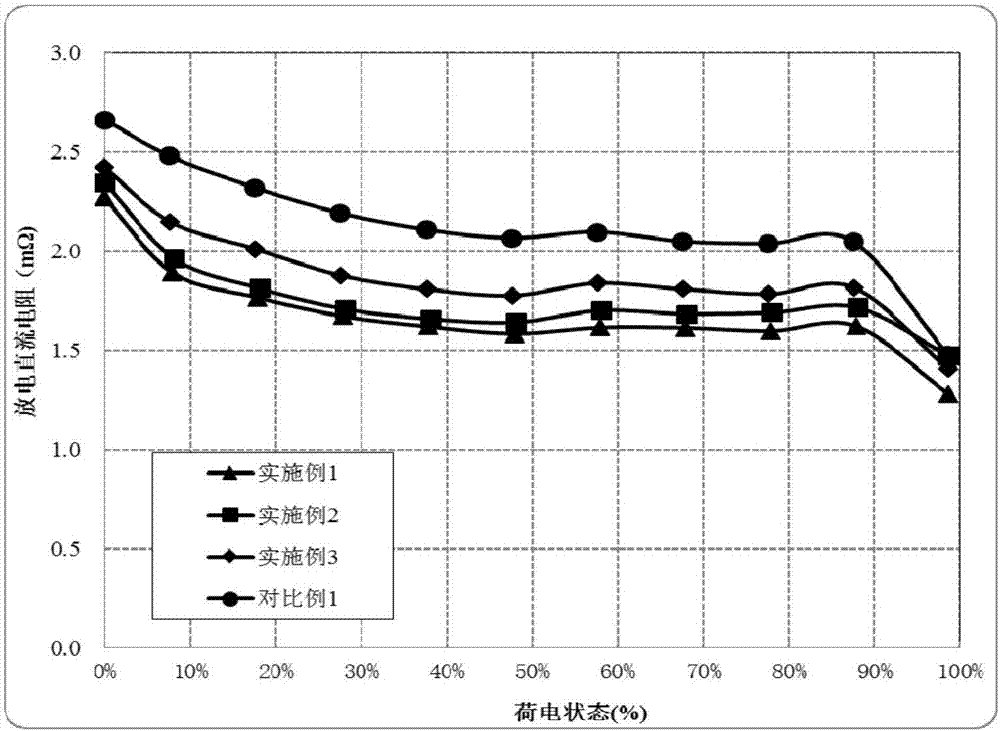

Embodiment 1

[0026] (1) Preparation of positive electrode slurry: LiNi with 96.33% mass ratio 0.5 mn 0.3 co 0.2 o 2 Cathode active material, 1.92% LiFePO 4 The positive electrode material, the carbon nanotube (CNT) conductive agent of 0.6% by mass ratio, and the polyvinylidene fluoride (PVDF) of 1.15% by mass ratio were added in N-methylpyrrolidone (NMP) respectively, and stirred at a rotating speed of 2000r / min Mix evenly to form positive electrode slurry.

[0027] (2) prepare negative electrode slurry: with the artificial graphite of 76.6% mass ratio, the natural graphite of 19.2% mass ratio, the conductive carbon black of 1% mass ratio, the carboxymethyl cellulose (CMC) of 1.5% mass ratio and 1.80% The mass ratio of styrene-butadiene rubber (SBR) was respectively added to the negative electrode solvent deionized water, stirred and mixed evenly at a rotation speed of 2500r / min to form the negative electrode slurry.

[0028] (3) Preparation of positive electrode sheet: The prepared p...

Embodiment 2

[0042] (1) Preparation of positive electrode slurry: LiNi with 92.9% mass ratio 0.6 mn 0.2 co 0.2 o 2 Cathode active material, 2.87% LiFePO 4 The positive electrode material, the carbon nanotube (CNT) conductive agent of 0.6% by mass ratio, and the polyvinylidene fluoride (PVDF) of 1.15% by mass ratio were added in N-methylpyrrolidone (NMP) respectively, and stirred at a rotating speed of 2000r / min Mix evenly to form positive electrode slurry.

[0043] (2) prepare negative electrode slurry: with the artificial graphite of 76.6% mass ratio, the natural graphite of 19.2% mass ratio, the conductive carbon black of 1% mass ratio, the carboxymethyl cellulose (CMC) of 1.5% mass ratio and 1.80% The mass ratio of styrene-butadiene rubber (SBR) was respectively added to the negative electrode solvent deionized water, stirred and mixed evenly at a rotation speed of 2500r / min to form the negative electrode slurry.

[0044] (3) Preparation of positive electrode sheet: The prepared po...

Embodiment 3

[0050] (1) Preparation of positive electrode slurry: LiNi with 91.9% mass ratio 0.8 mn 0.1 co 0.1 o 2 Cathode active material, 3.80% LiFePO 4 Positive electrode material, conductive carbon black and carbon nanotube (CNT) of 2.5% by mass ratio, polyvinylidene fluoride (PVDF) of 1.8% by mass ratio join in N-methylpyrrolidone (NMP) respectively, at rotating speed 3000r / min Stir and mix evenly to form positive electrode slurry;

[0051] (2) Preparation of negative electrode slurry: the primary particle lithium titanate of 9.05% mass ratio of artificial graphite, 81.45% mass ratio of natural graphite, 5% mass ratio of lithium titanate, 1% mass ratio of conductive carbon black, 1.5% mass ratio of Carboxymethyl cellulose (CMC) and 2.0% mass ratio of styrene-butadiene rubber (SBR) were added to the negative electrode solvent deionized water respectively, stirred and mixed evenly at a rotating speed of 2500r / min to form a negative electrode slurry;

[0052] (3) Preparation of posi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com