Meta-material loaded low cross-coupling antenna array

A technology of metamaterials and antenna arrays, applied in the field of antenna arrays loaded with metamaterials, can solve the problems of antenna pattern deterioration, affecting the efficiency of antenna arrays, affecting the matching of feeding networks, etc., to achieve broadband characteristics, ensure performance, and reduce processing effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

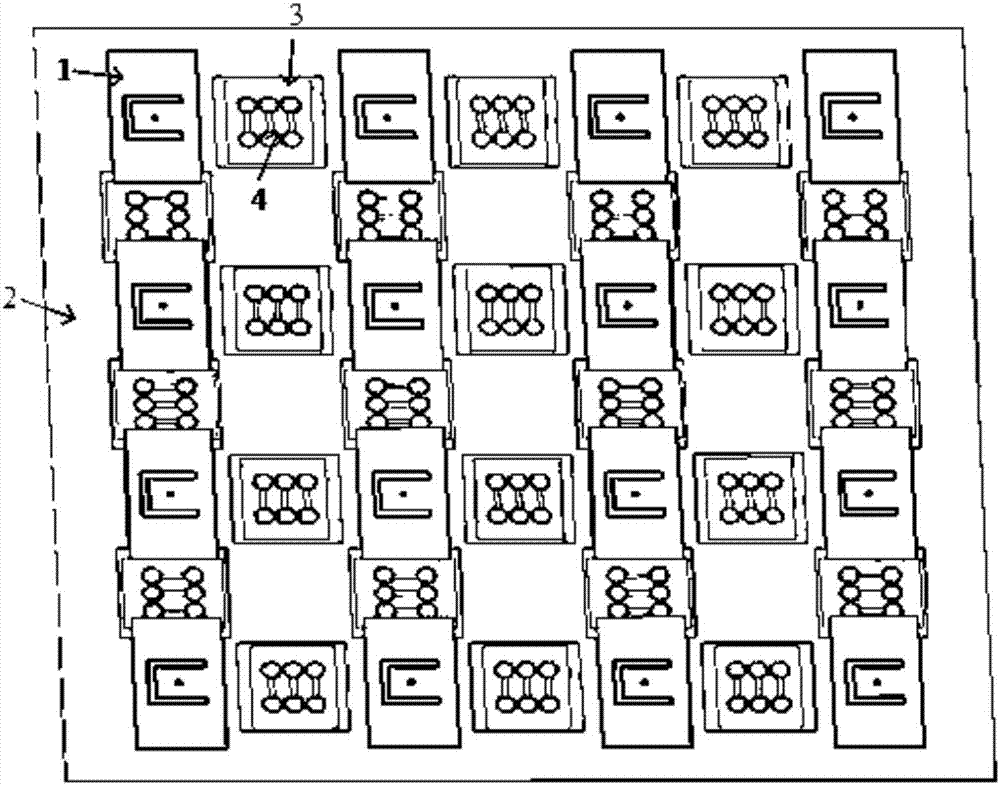

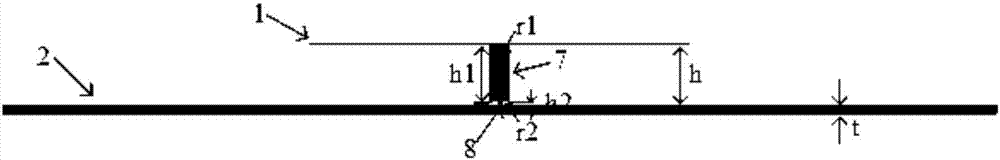

[0054] A metamaterial-loaded low-coupling antenna array, such as figure 1 As shown, it mainly includes metal patch 1, ground plane 2, metal connecting rod 7 and feeding probe 8. Metal patch 1 is connected to ground plane 2 through metal connecting rod 7 and feeding probe 8 in turn; ground plane 1 A dielectric substrate 3 is fixed on it, and the dielectric substrate 3 is distributed between two adjacent metal patches 1 .

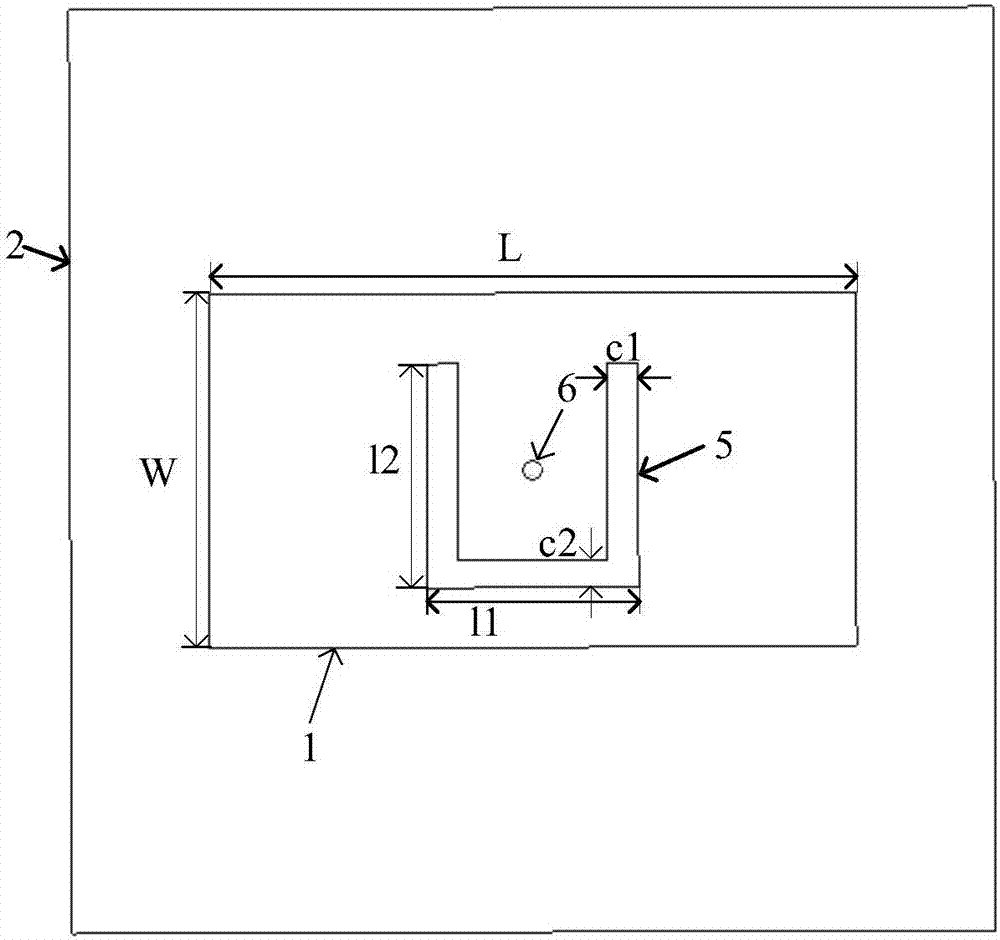

[0055] The metal patch 1 is a rectangular metal plate, but not limited to a rectangle. In this embodiment, there are metal patches 1 with an array number of 4×4=16, such as figure 2 As shown, the long side L=210mm of the metal patch 1, the wide side W=115mm, and the thickness is 2mm; the material of the metal patch 1 is copper, and a U-shaped groove 5 is opened in the middle of the upper surface of the metal patch 1, The opening direction of the U-shaped groove 5 is perpendicular to the long side of the metal patch 1. The U-shaped groove 5 includes two long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com