PE micro-porous filter

A microporous filter and microporous filtration technology, which is applied in the direction of membrane filter, fixed filter element filter, filtration separation, etc., can solve the problem of increasing the radial compressive strength, reducing the easy damage value of the tube, reducing the wall thickness, etc. problems, to achieve the effect of increasing the radial compressive strength, reducing the easy damage value of the tube, and improving the durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

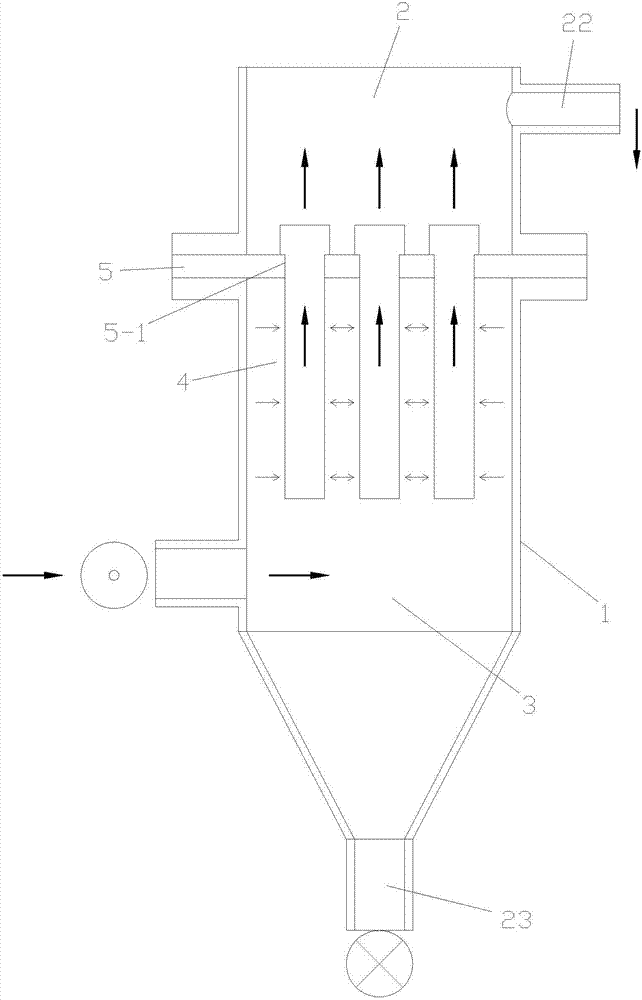

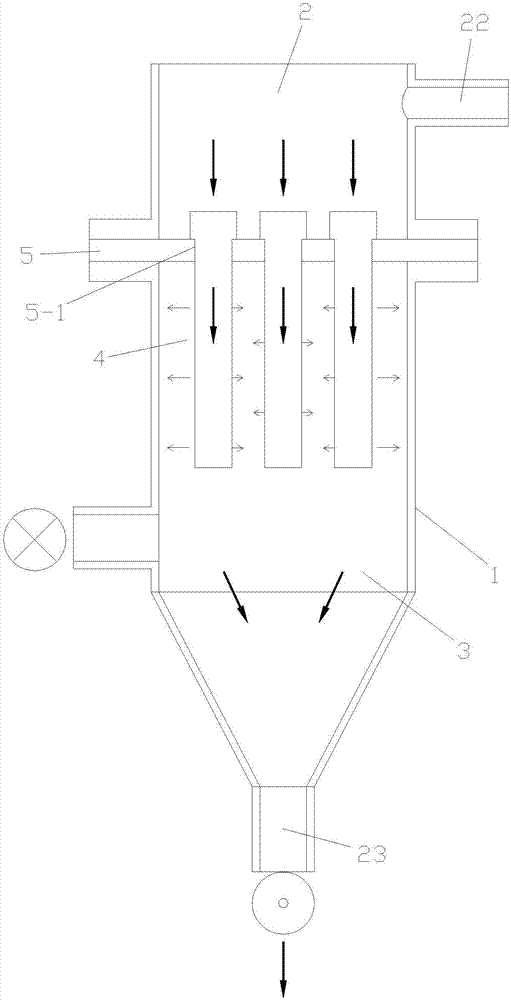

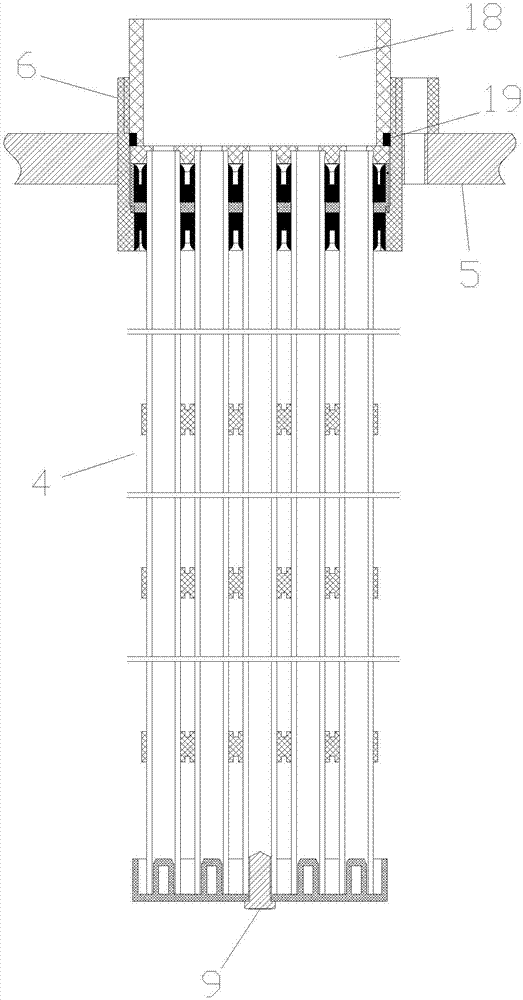

[0030] The present invention will be further described below in conjunction with accompanying drawing:

[0031] Referring to the accompanying drawings: this PE microporous filter includes a filter container 1, and the filter container 1 is provided with a clear liquid tank 2, a filter tank 3, a group of filter parts 4, and locking coils installed outside these filter parts 4 6 and the fixed plate 5 installed in the filter container 1, the fixed plate 5 is provided with an installation port 5-1 for the lock coil 6 to be installed in, the clear liquid tank 2 is located above the filter tank 3, between the two Separated by the fixed plate 5, the filter part 4 is provided with several groups of bundle tube groups 7, the bundle tube groups 7 are composed of several microporous filter tubes 7-1 made of PE material, inserted in a group of intervals outside the several groups of bundle tube groups 7 Distributed bundle tube fixing ring 8, the lower end of the bundle tube group 7 is equ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com