Mixing device for desulfurization of flue gas generated by thermal power generation

A thermal power generation and mixing device technology, which is applied to mixers, mixers with rotating stirring devices, gas treatment, etc., can solve the problems of polluting the environment, increasing the failure rate of stirring devices, and accelerating the use loss of stirring devices, so as to reduce damage degree, smooth operation, and the effect of avoiding hard collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

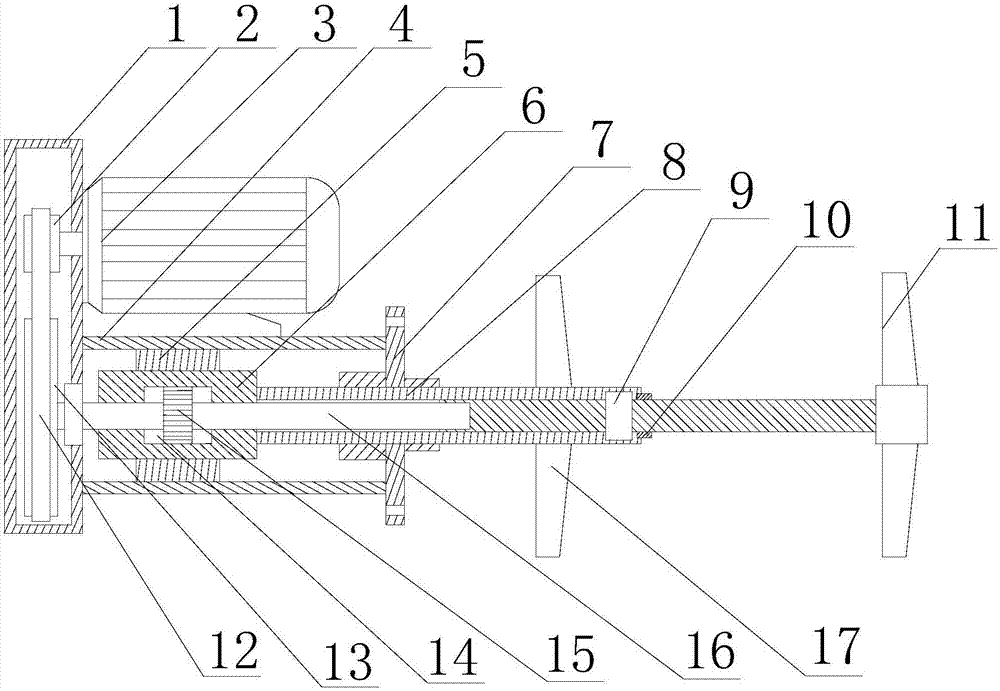

[0021] Such as figure 1 As shown, this embodiment includes a box body 1, a motor 3 and a fixed cylinder 4 arranged on the side wall of the box body 1, the motor 3 is arranged on the fixed cylinder 4, and the output end of the motor 3 runs through the side wall of the box body 1 Then continue to extend, the driving wheel 2 is installed on the extension section of the output end of the motor 3, and the end of the fixed cylinder 4 away from the box body 1 is equipped with a flange 7, and also includes a linkage shaft 16 arranged in the fixed cylinder 4 And the bearing 5 arranged on the inner peripheral wall of the fixed cylinder 4, the sleeve 8 is sleeved on the outer peripheral wall of the linkage shaft 16, the inner peripheral wall of the bearing 5 is in contact with the outer peripheral wall of the sleeve 8, One end of the sleeve 8 extends outwards after penetrating the flange 7, and an auxiliary vane 17 is fixed on the outer peripheral wall of the extension section of the sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com