Industrial wastewater treatment agent based on multi-effect phosphorus removal

A technology for industrial wastewater and treatment agents, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

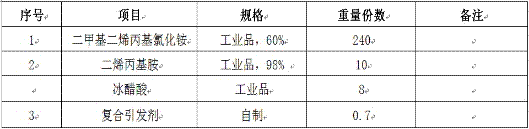

[0015] In a reaction kettle with a reflux condensing device, add 240 kg of dimethyl diallyl ammonium chloride cationic monomer, 10 kg of diallylamine, and 8 kg of glacial acetic acid, heat up to 82°C, and add the composite initiator 0.2kg, control the reaction temperature not to exceed 100°C, when it is naturally cooled to 82°C, then add 0.2kg of composite initiator, after the heating is completed, add 0.3kg of composite initiator, after the heating is completed, heat to 95°C and keep for 2 hours , to obtain cationic monomers. In another reactor, add 60 parts of water, 100 parts of industrial hydrochloric acid, 10 parts of ferric chloride, 60 parts of calcium aluminate, and stir the reaction. When the temperature rises to 80°C, add 10 parts of the cationic poly Raise the temperature to 90~95°C, react for 4 hours, discharge and mature for 24 hours to get the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com