Composite thermal-insulation mortar and preparation method thereof

A thermal insulation mortar and composite technology, applied in the field of construction mortar, can solve the problem that thermal insulation mortar cannot have both fireproof performance and thermal insulation performance, and achieve the effect of excellent thermal insulation performance and fireproof performance, improved strength, strength and fireproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

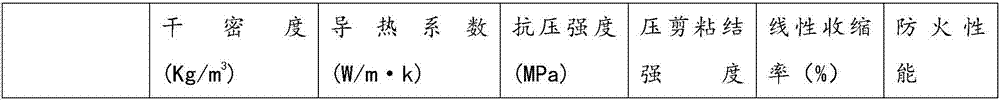

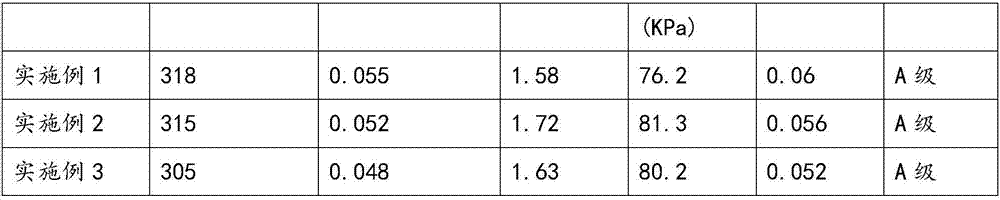

Embodiment 1

[0021] A preparation method of composite thermal insulation mortar, comprising the following steps:

[0022] (1) Weigh raw materials by weight: 150 parts of ordinary Portland cement, 80 parts of polystyrene particles, 60 parts of expanded perlite, 40 parts of nano ceramics, 18 parts of polypropylene fiber, 3 parts of air-entraining agent, fluorine 6 parts of leveling agent, 10 parts of redispersible latex powder;

[0023] (2) After the expanded perlite is dried, it is evenly mixed with nano-ceramic, and then coated with a coating machine to obtain expanded perlite whose surface is coated with nano-ceramic, and the redundant nano-ceramic is collected for subsequent use;

[0024] (3) Add polypropylene fiber, air-entraining agent, fluorine-based leveling agent, redispersible latex powder, and excess nano-ceramics in step (2) to ordinary Portland cement and stir, then add polyphenylene particles, and stir homogeneous, to obtain a premix;

[0025] (4) Add the expanded perlite who...

Embodiment 2

[0028] A preparation method of composite thermal insulation mortar, comprising the following steps:

[0029] (1) Weigh raw materials by weight: 100 parts of ordinary Portland cement, 80 parts of polystyrene particles, 60 parts of expanded perlite, 35 parts of nano ceramics, 15 parts of polypropylene fiber, 2 parts of air-entraining agent, fluorine 6 parts of leveling agent, 8 parts of redispersible latex powder;

[0030] (2) After the expanded perlite is dried, it is evenly mixed with nano-ceramic, and then coated with a coating machine to obtain expanded perlite whose surface is coated with nano-ceramic, and the redundant nano-ceramic is collected for subsequent use;

[0031] (3) Add polypropylene fiber, air-entraining agent, fluorine-based leveling agent, redispersible latex powder, and excess nano-ceramics in step (2) to ordinary Portland cement and stir, then add polyphenylene particles, and stir homogeneous, to obtain a premix;

[0032] (4) Add the expanded perlite whos...

Embodiment 3

[0035] A preparation method of composite thermal insulation mortar, comprising the following steps:

[0036] (1) Weigh raw materials by weight: 200 parts of ordinary Portland cement, 100 parts of polystyrene particles, 80 parts of expanded perlite, 50 parts of nano ceramics, 25 parts of polypropylene fiber, 5 parts of air-entraining agent, fluorine 8 parts of leveling agent, 15 parts of redispersible latex powder;

[0037] (2) After the expanded perlite is dried, it is evenly mixed with nano-ceramic, and then coated with a coating machine to obtain expanded perlite whose surface is coated with nano-ceramic, and the redundant nano-ceramic is collected for subsequent use;

[0038] (3) Add polypropylene fiber, air-entraining agent, fluorine-based leveling agent, redispersible latex powder, and excess nano-ceramics in step (2) to ordinary Portland cement and stir, then add polyphenylene particles, and stir homogeneous, to obtain a premix;

[0039] (4) Add the expanded perlite wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com