Grafted polyethylene hot melt adhesive for steel wire net framework PE (Polyethylene) tube and preparation method

A technology of grafting polyethylene and steel mesh, applied in the direction of grafting polymer adhesives, adhesives, adhesive types, etc., can solve the problem of persistent decline in peel strength of hot melt adhesives, inability to achieve high shear strength, Problems such as reduced product fluidity, to achieve excellent composite effects, excellent product fluidity, and strong adhesive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

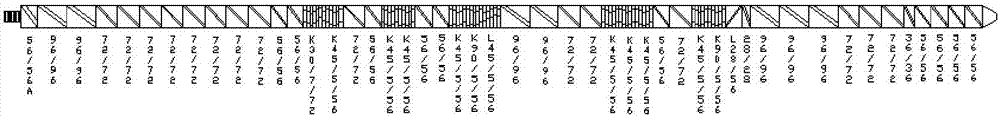

Image

Examples

Embodiment 1

[0027] The grafted polyethylene hot-melt adhesive used for the steel mesh skeleton PE pipe, in parts by mass, its components include:

[0028] 100 parts of compound carrier (50 parts of HDPE; 10 parts of POE; 10 parts of LDPE: 30 parts of LLDPE);

[0029] 0.3 parts of composite initiator (0.1 part of dicumyl peroxide; 0.2 part of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane);

[0030] 3 parts of maleic anhydride;

[0031] Prepare according to the above preparation method, and apply the prepared product to the steel mesh skeleton PE pipe, and test the related properties, see Table 1.

Embodiment 2

[0033] The grafted polyethylene hot-melt adhesive used for the steel mesh skeleton PE pipe, in parts by mass, its components include:

[0034] 100 parts of compound carrier (50 parts of HDPE; 10 parts of POE; 10 parts of LDPE: 30 parts of LLDPE);

[0035] 0.23 parts of composite initiator (0.09 parts of dicumyl peroxide; 0.14 parts of 2,5-dimethyl-2,5-bis(tert-butyl peroxide) hexane);

[0036] 2.3 parts of maleic anhydride;

[0037] Prepare according to the above preparation method, and apply the prepared product to the steel mesh skeleton PE pipe, and test the related properties, see Table 1.

Embodiment 3

[0039] The grafted polyethylene hot-melt adhesive used for the steel mesh skeleton PE pipe, in parts by mass, its components include:

[0040] 100 parts of compound carrier (50 parts of HDPE; 10 parts of POE; 10 parts of LDPE: 30 parts of LLDPE);

[0041] 0.16 parts of composite initiator (0.06 parts of dicumyl peroxide; 0.1 part of 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane);

[0042] 1.6 parts of maleic anhydride;

[0043] Prepare according to the above preparation method, and apply the prepared product to the steel mesh skeleton PE pipe, and test the related properties, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com