Small brick kiln smoke waste heat utilization device based on Stirling engine

A Stirling engine and flue gas waste heat technology, which is applied to hot gas variable displacement engine devices, machines/engines, waste heat treatment, etc., can solve problems such as cost reduction, flue gas waste heat waste, and heat source pollution, so as to reduce heat source pollution , reduce energy waste, reduce the effect of exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

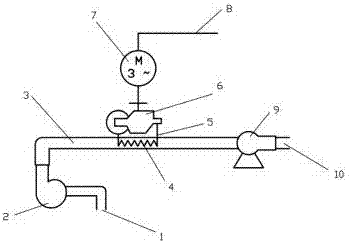

[0012] The patent of the present invention will be described in detail below in conjunction with the embodiments shown in the accompanying drawings.

[0013] The labels in the figure are: 1. Kiln waste heat source 2. Induced fan 1 3. Flue gas pipe 4. Fin 5. Heat exchanger 6. Stirling engine 7. Generator 8. Electric energy output 9. Induced fan 2 10. Lack of steam.

[0014] Its structure consists of: flue, induced draft fan, Stirling engine (main body), heat exchanger, heat exchanger fins, generator. The high-temperature flue gas is sucked into the flue gas pipe (3) by the induced draft fan 1 (2) from the waste heat source (1) of the kiln, and the working fluid in the heat exchanger (5) is in the flue gas duct (3) and the high-temperature flue gas At the same time, the fins (4) on the heat exchanger (5) play a role in improving the heat transfer efficiency, and the temperature of the flue gas drives the Stirling engine (6) to run, thereby driving the generator (7) to generate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com