High-temperature lubricants

A high-temperature, high-temperature oil technology, used in high-temperature greases for continuous use temperatures up to 250 ° C, in the field of oils and greases, can solve problems such as long functional duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 2

[0067] Preparation of high temperature oil according to the invention

[0068] The long-chain ester or aliphatically substituted naphthalene is preset in a stirred boiler. At 100° C., polyisobutene and optionally another oil are added thereto under stirring. Subsequently, the mixture was stirred for 1 h in order to obtain a homogeneous mixture. The antiwear additives and antioxidants were added to the boiler at 60°C with stirring. After about 1 hour, the finished oil can be filled into the provided containers.

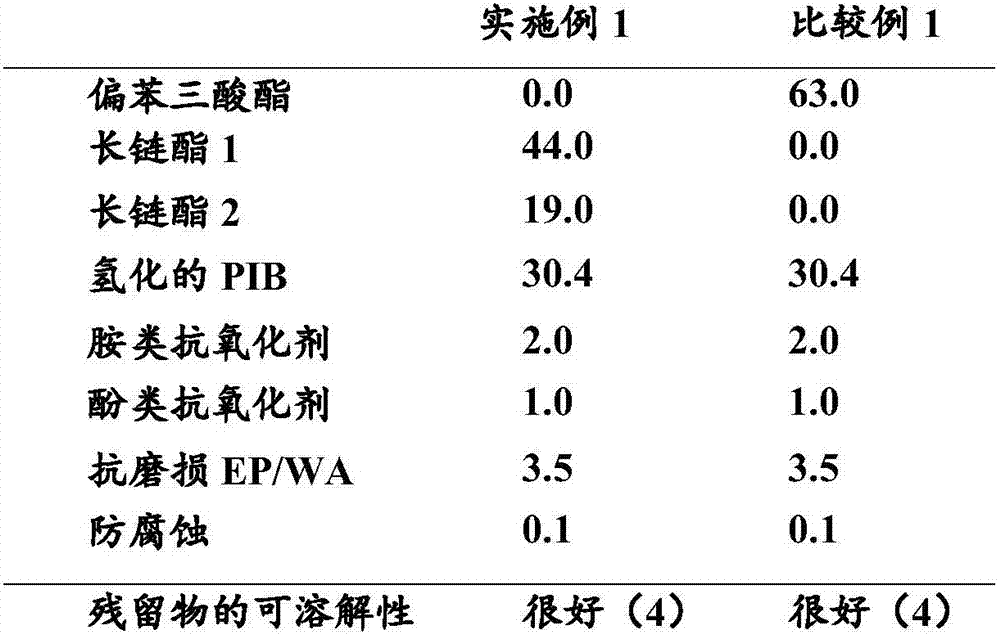

[0069] Composition of high temperature oil:

[0070] Table 1

[0071]

[0072] Table 2

[0073]

[0074] Base data for the oil examples can be derived from Table 3.

[0075] table 3

[0076]

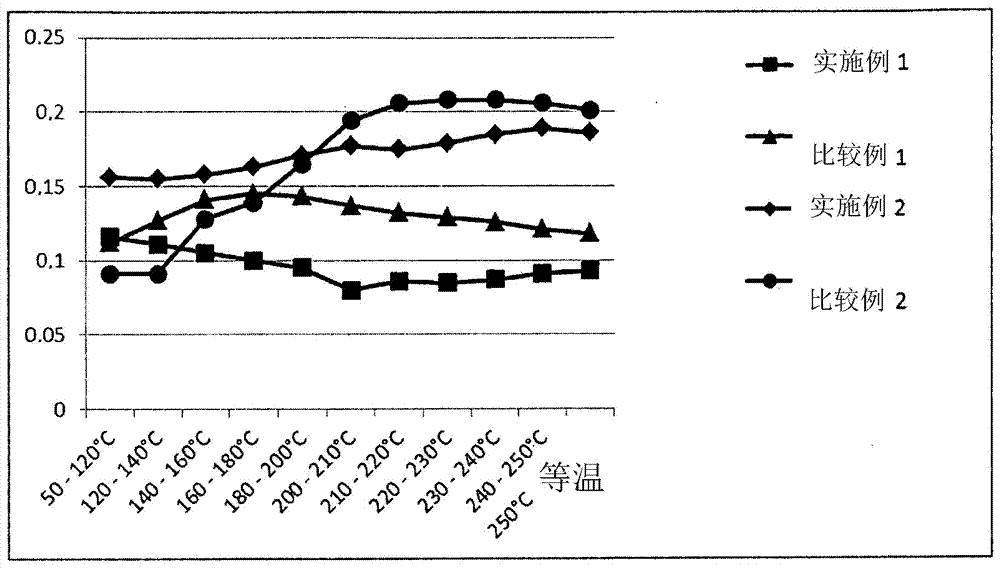

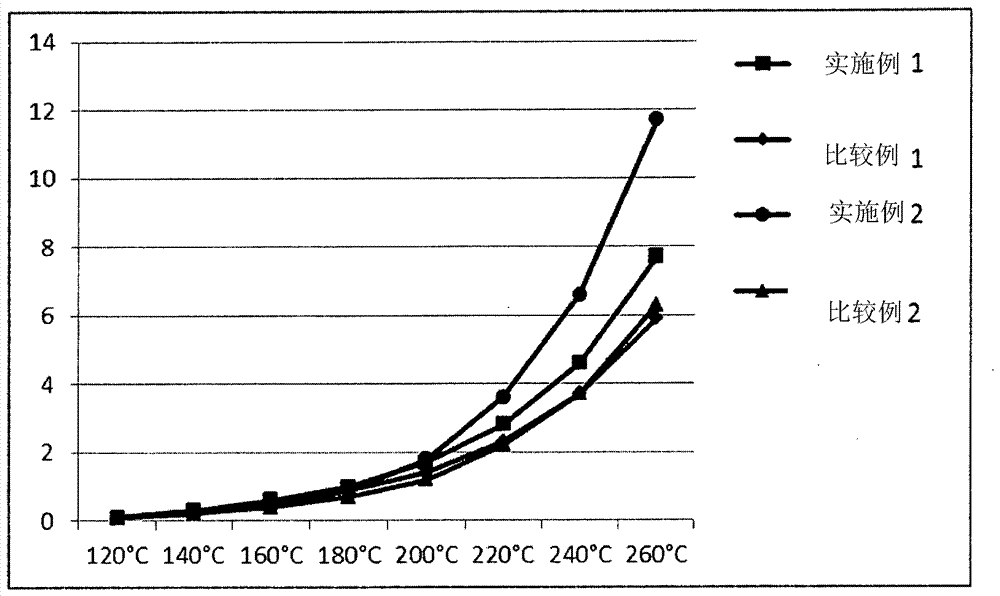

[0077] In addition, the friction properties of the oil were measured in SRV and the evaporative losses in dynamic TGA according to DIN 51834-2. The results are shown in Tables 4 and 5 and in figure 1 and 2 shown in the graph.

[0078] Table 4

[0079]

[008...

Embodiment 3 to 8

[0084] Preparation of high temperature grease according to the invention

[0085] The base oil is preset in the stirred boiler. Polyisobutene and optionally another oil and thickener are added thereto with stirring at 100°C.

[0086] The thickener is produced by in situ reaction of the reactants employed in the base oil. Subsequently, the mixture was heated to 150°C to 210°C, stirred for several hours and cooled again. During cooling, at about 60°C, the required antiwear additives, antioxidants and anticorrosion additives are added thereto. A homogeneous mixture of greases is obtained by a final homogenization step via rollers, colloid mill or Gaulin.

[0087] The composition of the high temperature grease is shown in Table 6.

[0088] Table 6

[0089]

[0090]

Embodiment 3

[0092] Example 3: LiOH, 12-hydroxystearic acid, azelaic acid

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com