Acidic lactase and zinc compound preparation and preparation method thereof

A technology of acid lactase and compound preparations, applied in the field of medical care, can solve problems such as insufficient intake of galactose, unsuitable for long-term use, impact on brain development, etc., to improve lactose intolerance, improve lactose intolerance, The effect of improving human memory function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

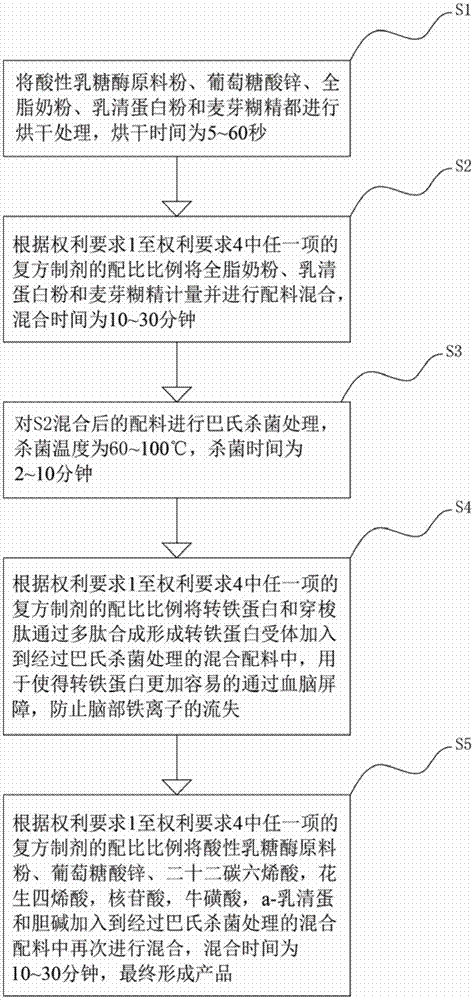

Method used

Image

Examples

Embodiment 1

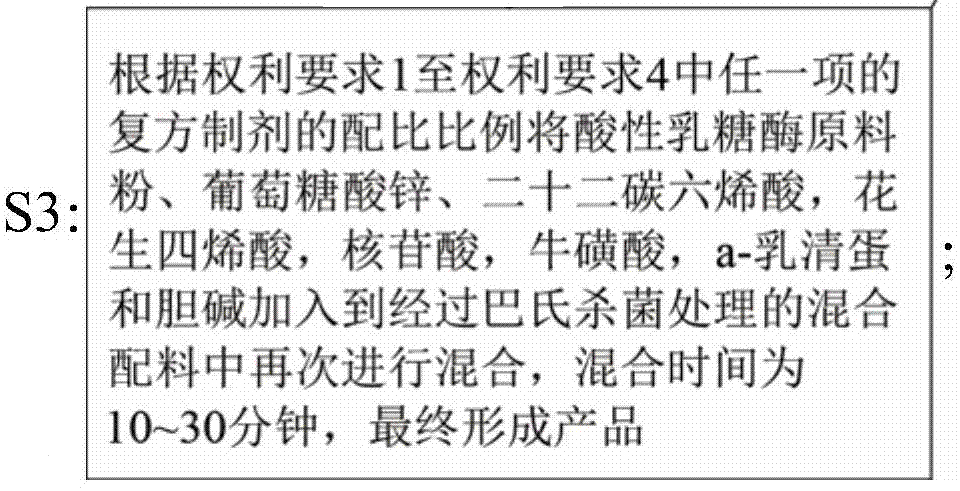

[0030] Embodiment 1: the compound preparation in the present embodiment is made up of following components and the consumption by weight percentage: acid lactase raw material powder 9%, zinc gluconate 0.7%, whole milk powder 55.8%, whey protein powder 10%, Maltodextrin 20.3%, docosahexaenoic acid 0.8%, arachidonic acid 0.7%, nucleotide 0.9%, transferrin 0.5%, shuttle peptide 0.6%, choline 0.7%.

[0031] Preparation method: Dry zinc gluconate, whole milk powder, whey protein powder and maltodextrin with hot air for 15 seconds, dry the raw material powder of acid lactase with cold air for 10 seconds. 15 seconds; then measure whole milk powder, whey protein powder and maltodextrin according to the above ratio and mix the ingredients. The mixing time is 20 minutes; pasteurize the mixed ingredients at a temperature of 85 ℃, and the sterilization time is 5 minutes. According to the ratio of the above-mentioned compound preparation, transferrin and shuttle peptide are synthesized by ...

Embodiment 2

[0032] Embodiment 2: the compound preparation in the present embodiment is made up of following components and the consumption by weight percentage: acid lactase raw material powder 4%, zinc gluconate 1.2%, whole milk powder 61.8%, whey protein powder 5%, Maltodextrin 23.3%, docosahexaenoic acid 0.9%, arachidonic acid 0.8%, nucleotide 0.8%, transferrin 0.6%, shuttle peptide 0.7%, choline 0.9%.

[0033]Preparation method: Dry zinc gluconate, whole milk powder, whey protein powder and maltodextrin with hot air for 5 seconds, dry the acid lactase raw material powder with cold air for 5 seconds 5 seconds; then measure whole milk powder, whey protein powder and maltodextrin according to the above ratio and mix the ingredients. The mixing time is 10 minutes; pasteurize the mixed ingredients at a temperature of 100 ℃, and the sterilization time is 2 minutes. According to the ratio of the above-mentioned compound preparation, transferrin and shuttle peptide are synthesized by polypept...

Embodiment 3

[0034] Embodiment 3: the compound preparation in the present embodiment is made up of following components and the consumption by weight percentage: acid lactase raw material powder 14%, zinc gluconate 1.2%, whole milk powder 38%, whey protein powder 15%, Maltodextrin 27.3%, docosahexaenoic acid 1.1%, arachidonic acid 0.4%, nucleotide 1%, transferrin 0.8%, shuttle peptide 0.2%, choline 1%.

[0035] Preparation method: Dry zinc gluconate, whole milk powder, whey protein powder and maltodextrin with hot air for 20 seconds, dry the acid lactase raw material powder with cold air for 20 seconds 20 seconds; then measure whole milk powder, whey protein powder and maltodextrin according to the above ratio and mix the ingredients. The mixing time is 25 minutes; pasteurize the mixed ingredients at a temperature of 90 ℃, and the sterilization time is 7 minutes. According to the ratio of the above-mentioned compound preparation, transferrin and shuttle peptide are synthesized by polypepti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com