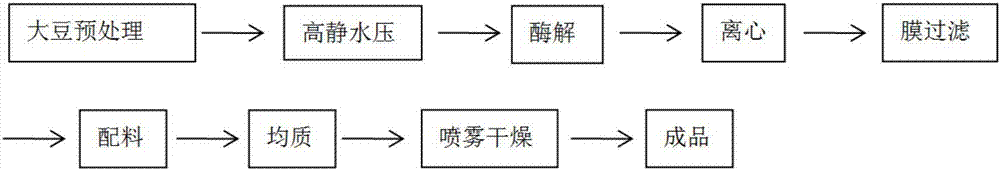

Method for preparing hypoallergenic bean powder by combining high hydrostatic pressure, enzymolysis and membrane filtering

A technology of high hydrostatic pressure and combined preparation, applied in the field of soy product production, can solve the problems of poor sensitization reduction effect, unsatisfactory sensitization effect, incomplete enzymatic hydrolysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Dry the dehulled soybeans at 80°C for 20 minutes, and then grind them into soybean powder for use; dissolve the soybean powder in water at a concentration of 1%, adjust the pH of the mixture to 6.8 with 1M HCl, and maintain the temperature of the water in the reactor at 20°C , soy flour was treated with high hydrostatic pressure at 300MPa for 15 minutes, and the treated sample was freeze-dried; the treated soybean flour was subjected to enzymatic hydrolysis, and the enzymatic hydrolysis conditions: the mixing ratio of soybean flour and water was 1:6, and the enzymatic hydrolysis temperature was 55 ℃, the pH of enzymolysis is 6, the selected enzyme is papain, the amount of papain added is 0.05% of the total mass of soybean flour obtained in step (1), the enzymolysis time is 10min, and the enzyme is deactivated at 80°C after enzymolysis is completed For 3 minutes, use a horizontal centrifuge to centrifuge the enzymatic solution at 4500r / min, room temperature, 10 minutes, d...

Embodiment 2

[0033] Dry the dehulled soybeans at 80°C for 20 minutes, and then grind them into soybean powder for use; dissolve the soybean powder in water at a concentration of 1%, adjust the pH of the mixture to 6.8 with 1M HCl, and maintain the temperature of the water in the reactor at 20°C , soy flour was treated with high hydrostatic pressure at 200MPa for 20 minutes, and the treated sample was freeze-dried; the treated soybean flour was subjected to enzymolysis, and the enzymatic hydrolysis conditions: the mixing ratio of soybean flour and water was 1:6, and the enzymatic hydrolysis temperature was 55 ℃, the enzymolysis pH is 7, the selected enzyme is papain, the amount of papain added is 0.05% of the total mass of soybean flour obtained in step (1), the enzymolysis time is 10min, and the enzyme is deactivated at 80°C after the enzymolysis is completed For 3 minutes, use a horizontal centrifuge to centrifuge the enzymatic solution at 4500r / min, room temperature, 10 minutes, discard t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com