Tail gas treatment system and apparatus for continuously preparing nanometer carbon material

A nano-carbon material and tail gas treatment technology, which is applied in the direction of nano-carbon, gas treatment, climate sustainability, etc., can solve problems such as tail gas treatment, achieve safe and reliable use, reduce energy consumption, reduce labor costs and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

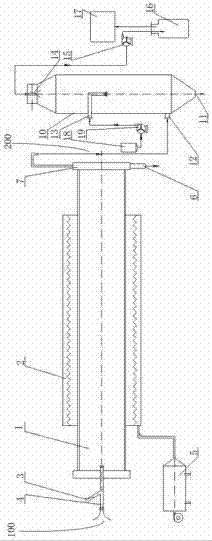

Image

Examples

Embodiment 1

[0030] The continuous preparation of carbon nanotubes by catalytic cracking of methane comprises the following steps:

[0031] Step 1, close the feed pipe 3 and the discharge pipe 6, open the exhaust pipe 7, and the inlet pipe 4 is connected to nitrogen, and passed into the reactor 1 for 10 minutes; repeat 3 times, to remove the air in the reactor 1;

[0032] Step 2, adjust the inclination angle of reactor 1 to 0 degrees, rotate at a speed of 8~20r / min, heat the heating furnace 2 to 500~600°C, replace the gas in the inlet pipe 4 with hydrogen, and replace the La2NiO4 in the feed pipe 3 Catalyst powder enters reactor 1 with hydrogen, and the catalyst is reduced for 20-30 minutes;

[0033] Step 3, adjust the temperature of the heating furnace 2 to 700°C~900°C, adjust the inclination angle of the reactor 1 to -5~-8 degrees, and reverse the rotation at a speed of 10~15r / min for 10~20min; replace the gas in the inlet pipe 4 For methane, adjust the inclination angle of reactor 1 to...

Embodiment 2

[0038] The continuous preparation of nano-onion carbon by catalytic cracking of coalbed gas includes the following steps:

[0039] Step 1, close the feed pipe 3 and the discharge pipe 6, open the exhaust pipe 7, and the inlet pipe 4 is connected to nitrogen, and passed into the reactor 1 for 10 minutes; repeat 3 times, to remove the air in the reactor 1;

[0040] Step 2, adjust the inclination angle of reactor 1 to 0 degrees, rotate at a speed of 5~15r / min, heat the heating furnace 2 to 500~600°C, replace the gas in the inlet pipe 4 with hydrogen, and replace the Ni in the feed pipe 3 - Fe alloy catalyst powder enters reactor 1 with hydrogen, and reduces the catalyst for 20-30 minutes;

[0041] Step 3, adjust the temperature of the heating furnace 2 to 700°C~900°C, adjust the inclination angle of the reactor 1 to -3~-6 degrees, and reverse the rotation at a speed of 8~12r / min for 10~20min; replace the gas in the inlet pipe 4 For coalbed methane, adjust the inclination angle o...

Embodiment 3

[0046] The continuous preparation of graphene by catalytic cracking of natural gas comprises the following steps:

[0047] Step 1, close the feed pipe 3 and the discharge pipe 6, open the exhaust pipe 7, and the inlet pipe 4 is connected to nitrogen, and passed into the reactor 1 for 10 minutes; repeat 3 times, to remove the air in the reactor 1;

[0048] Step 2, adjust the inclination angle of reactor 1 to 0 degrees, rotate at a speed of 5~15r / min, heat the heating furnace 2 to 600~700°C, replace the gas in the inlet pipe 4 with natural gas, and replace the catalyst in the feed pipe 3 Cu powder enters reactor 1 with hydrogen, and reduces the catalyst for 20-30 minutes;

[0049] Step 3, adjust the temperature of the heating furnace 2 to 900°C~1000°C, adjust the inclination angle of the reactor 1 to -3~-5 degrees, and reverse the rotation at a speed of 10~12r / min for 15~25min; replace the gas in the inlet pipe 4 For natural gas, adjust the inclination angle of reactor 1 to 6~8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com