Device and method for decreasing recast layer caused by laser micropore processing

A technology of microhole processing and processing equipment, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of easy damage to the matrix structure of the inner wall of the hole, reduce the efficiency of laser microhole processing, and damage the structure of the inner wall of the microhole, etc. Achieve the effects of reducing the probability of recasting layer and microcracks, increasing the processing speed of microholes, and accelerating the drilling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The details and working conditions of the method and device proposed by the present invention will be described in detail below in conjunction with the accompanying drawings and through specific implementation methods. It should be understood that the specific embodiments described here are only used to explain the present invention and are not intended to limit the present invention.

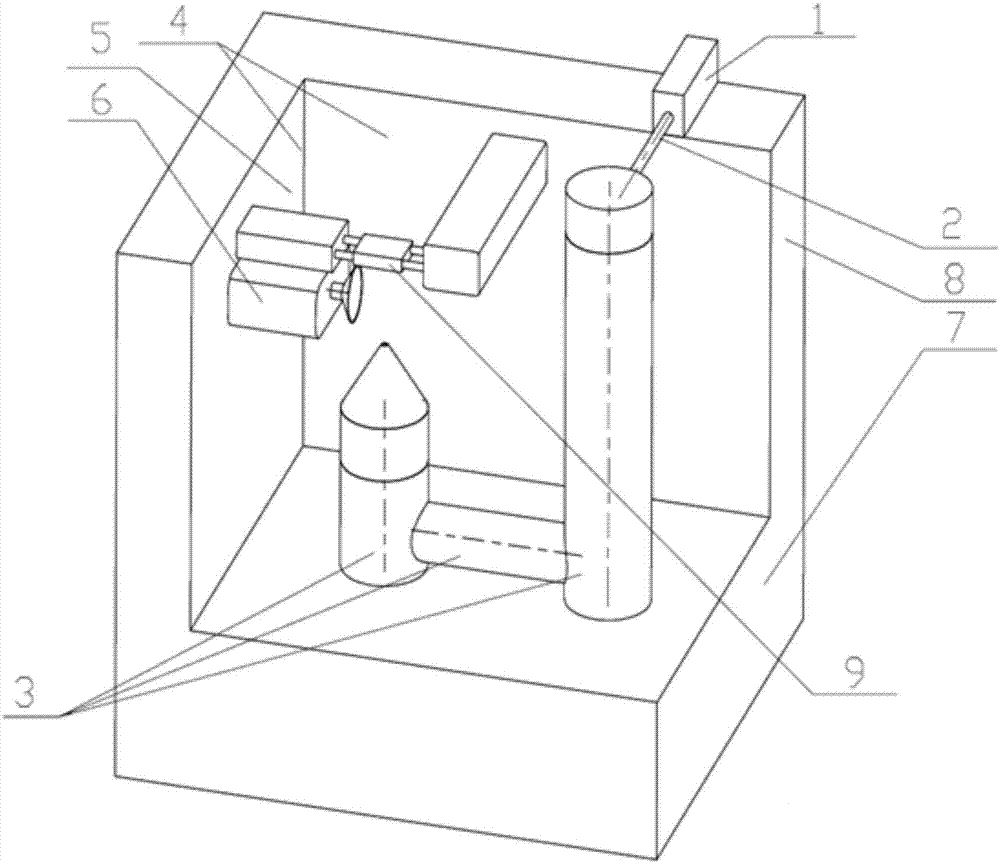

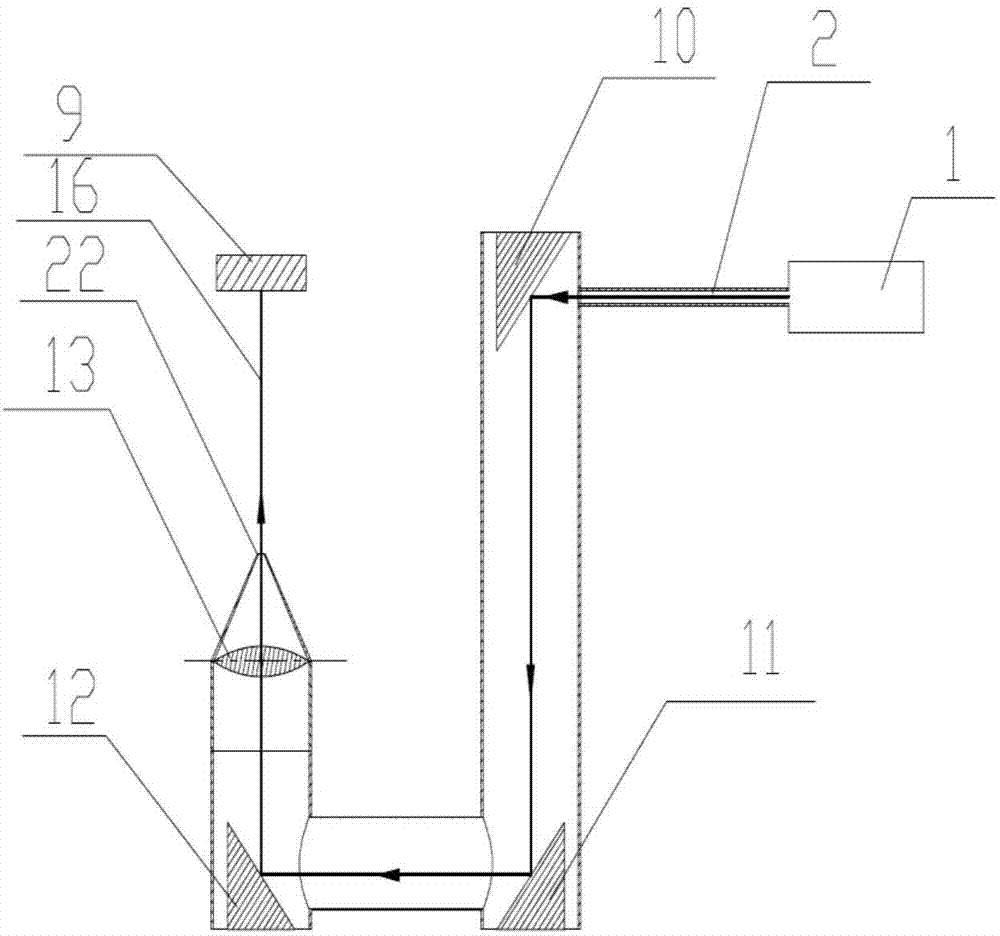

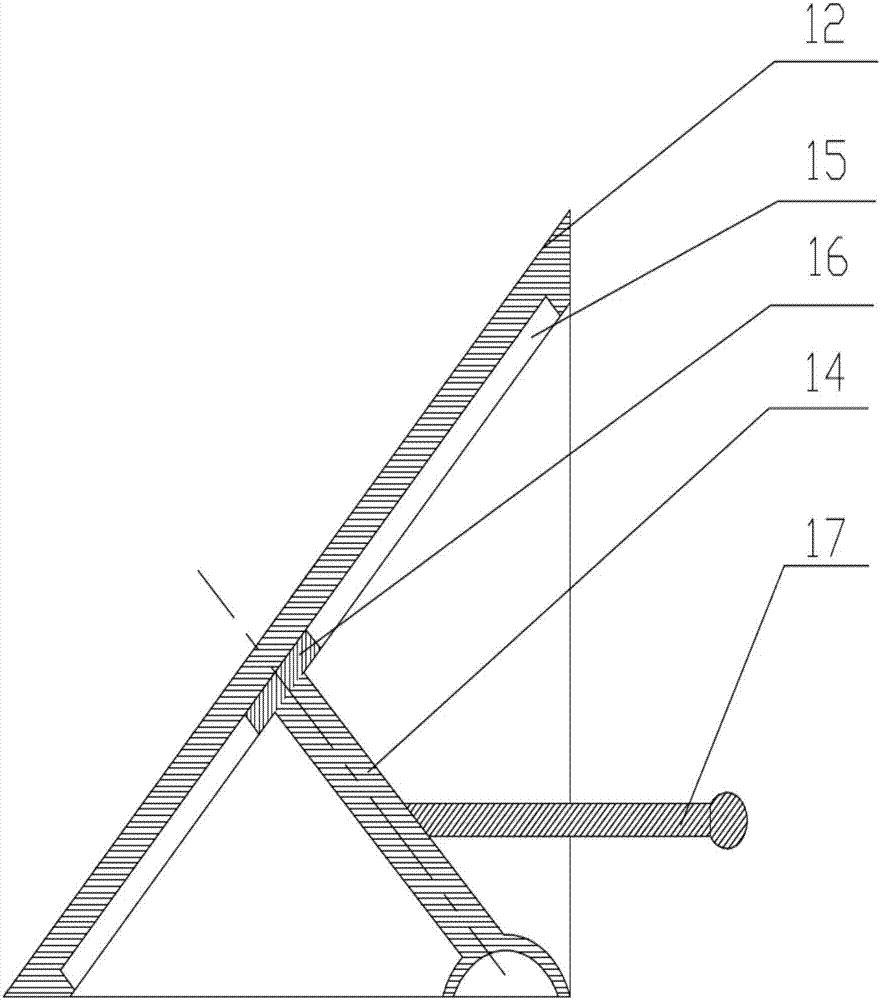

[0042] combined with Figure 1-5 As shown, the processing device for reducing the recast layer caused by laser microhole processing provided by the present invention includes a laser generator 1, an optical path reflection mechanism 3, an object loading mechanism 4, a spatter recovery device 5, a power supply box 6, and a machine tool base 7. The bed 8 of the machine tool, wherein the laser generator 1 is connected with the optical path reflection mechanism 3 through the conduit 2 .

[0043] The laser generator 1 is relatively fixedly arranged on the upper side of the workpiece 9 , the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap