Working method of glass carrying robot with cooling function

A technology for handling robots and working methods, which is applied in the field of mechanical equipment, can solve the problems of no cooling measures, complicated operation process, and low work efficiency, and achieve the effects of good lighting effect, guaranteed accuracy, and small labor workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

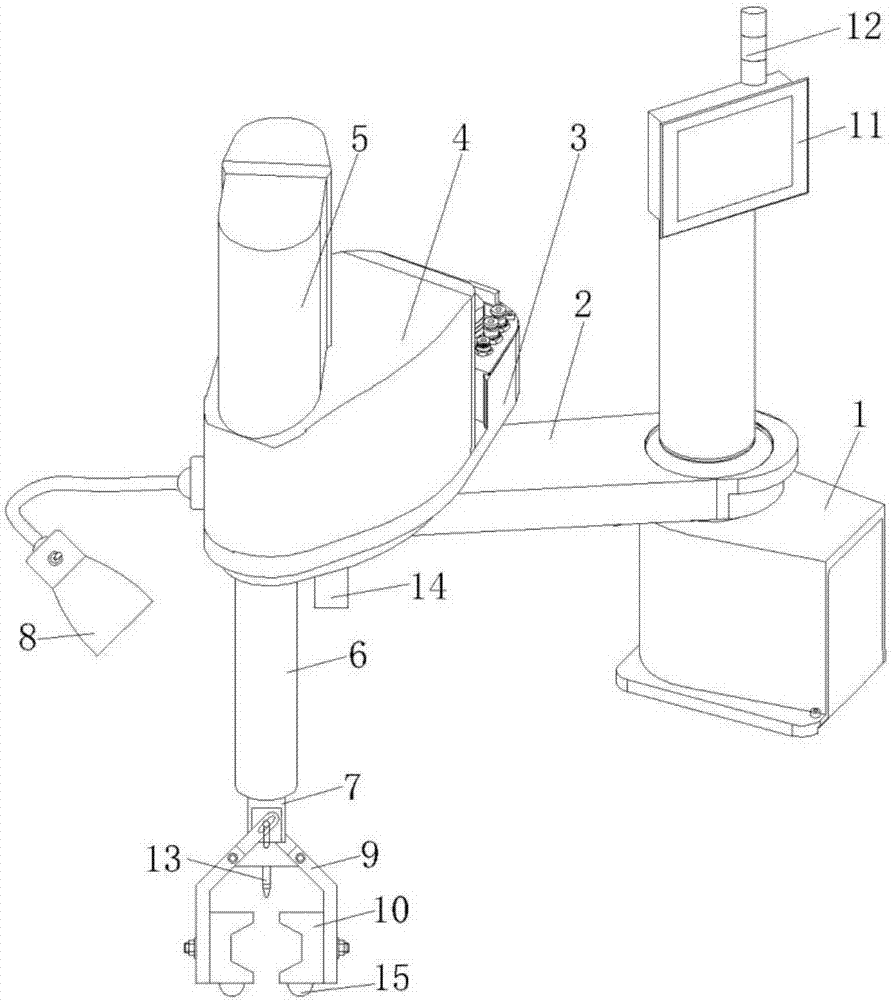

[0030] Such as figure 1 As shown, the working method of a glass handling robot with cooling function in this embodiment, the specific working steps are as follows:

[0031] (1), first start the power supply, and the staff sets the specific operating parameters of the robot through the PLC controller 11;

[0032] (2) The first joint axis 2 and the second joint axis 3 are driven by the servo motor inside the fuselage 1 to move to the predetermined position according to the PLC control program;

[0033] (3) The cylinder 5 drives the telescopic sleeve 6 to move downward;

[0034] (4) The telescopic sleeve 6 drives the clamping mechanism 9 to move downward through the coupling 7, and at the same time, the visual detection mechanism 14 recognizes the outline of the glass, judges the exact position of the glass and sends it to the PLC controller 11;

[0035] (5) According to the feedback information from the visual detection mechanism 14, after the clamping mechanism 9 calibrates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com