Dimethyl isophthalate and its production method

A technology of dimethyl isophthalate and a production method, which is applied to the field of dimethyl isophthalate and its production, can solve the problems of low product yield, high equipment requirements and high production cost, and achieves low reaction temperature , The effect of short esterification time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

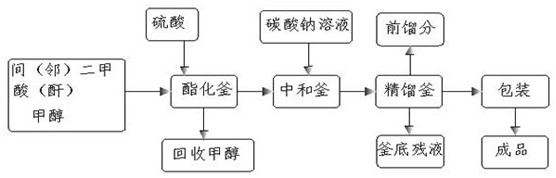

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of dimethyl isophthalate and production method thereof

[0030] Include the following steps:

[0031] 1) Reaction: Weigh isophthalic acid, methanol and catalyst in the reaction kettle for reaction;

[0032] The reaction is heated by steam, the temperature is 100-130°C, the pressure is 0.2-0.6MPa, and the reaction time is 3 hours;

[0033] The mass ratio of the isophthalic acid, methanol and concentrated sulfuric acid is 1:3-4:0.001-0.003;

[0034] The catalyst is concentrated sulfuric acid.

[0035] 2) Dealcoholization: Slowly open the alcohol steaming valve, gradually reduce the pressure and temperature in the reactor, and at a temperature of 100-130°C and a pressure of normal pressure, dealcoholize the product obtained in step 1) to obtain esterification feedstock and methanol;

[0036] The methanol is condensed by a condenser and recovered for future use.

[0037] 3) Alkali washing: Put the crude product obtained in step 2) into a neutralizat...

Embodiment 2

[0043] Embodiment 2 A kind of production method of dimethyl isophthalate

[0044] Include the following steps:

[0045] 1) Reaction: Weigh isophthalic acid, methanol and catalyst in the reaction kettle for reaction;

[0046] The reaction is heated by steam, the temperature is 100-102°C, the pressure is 0.2-0.25MPa, and the reaction time is 3 hours;

[0047] The mass ratio of the isophthalic acid, methanol and concentrated sulfuric acid is 1:3:0.001;

[0048] The catalyst is concentrated sulfuric acid.

[0049] 2) Dealcoholization: Slowly open the alcohol steaming valve, gradually reduce the pressure and temperature in the reactor, and at a temperature of 100-105°C and a pressure of normal pressure, dealcoholize the product obtained in step 1) to obtain esterification feedstock and methanol;

[0050] The methanol is condensed by a condenser and recovered for future use.

[0051] 3) Alkali washing: Put the crude product obtained in step 2) into a neutralization kettle, add ...

Embodiment 3

[0057] Embodiment 3 A kind of dimethyl isophthalate and production method thereof

[0058] Include the following steps:

[0059] 1) Reaction: Weigh isophthalic acid, methanol and catalyst in the reaction kettle for reaction;

[0060] The reaction is heated by steam, the temperature is 125-130°C, the pressure is 0.55-0.6MPa, and the reaction time is 3 hours;

[0061] The mass ratio of the isophthalic acid, methanol and concentrated sulfuric acid is 1:4:0.003;

[0062] The catalyst is concentrated sulfuric acid.

[0063] 2) Dealcoholization: Slowly open the alcohol steaming valve, gradually reduce the pressure and temperature in the reactor, and at a temperature of 125-129.5°C and normal pressure, dealcoholize the product obtained in step 1) to obtain esterification feedstock and methanol;

[0064]The methanol is condensed by a condenser and recovered for future use.

[0065] 3) Alkali washing: Put the crude product obtained in step 2) into a neutralization kettle, add 5-8%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com