Injectable hydrogel as well as preparation method and application thereof

A technology for injecting water and gel, applied in the fields of pharmaceutical formulation, medical science, surgery, etc., can solve the problems of high price of fibrin glue and poor resistance to enzymatic hydrolysis, and achieve the effect of remarkable anti-enzymatic hydrolysis ability and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

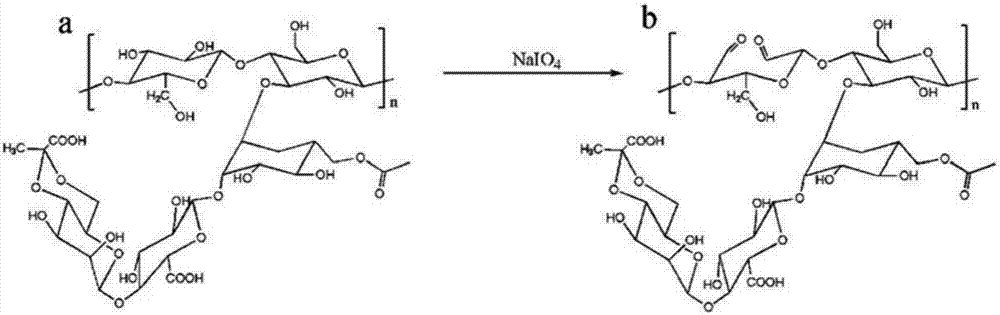

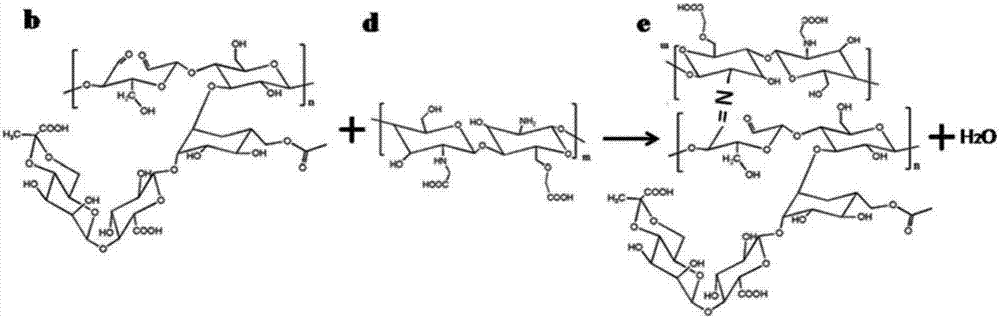

[0045] 1. Synthesis of aldehydelated xanthan gum: prepare 0.6% (w / v) xanthan gum aqueous solution and 8% (w / v) NaIO 4 aqueous solution, then pour 80ml xanthan gum aqueous solution into a beaker and add 2ml NaIO dropwise 4 Aqueous solution (xanthan gum and NaIO 4 The molar ratio is 1:1.5); after that, the mixture was stirred for 3h in the dark; then 1ml of ethylene glycol was added to neutralize the unreacted NaIO 4 , the reaction was stirred for another 1 h, and the solution was purified with distilled water using a dialysis bag for 3 days, and the water was renewed 5 times a day during the dialysis; finally, the Xan-CHO product was freeze-dried in a freeze dryer, and then sealed at 4 °C Store in a plastic bag.

[0046] The degree of oxidation (proportion of oxidized xanthic acid repeating units) of Xan-CHO was determined by hydroxylamine hydrochloride titration. Dissolve 5ml xanthan gum CHO aqueous solution (0.2%w / v) in 15ml hydroxylamine hydrochloride solution (2.3%w / v), ...

Embodiment 2

[0059] 1, the synthesis of aldehydated xanthan gum: prepare 0.5% (w / v) xanthan gum aqueous solution and 5% (w / v) NaIO 4 aqueous solution, then pour the xanthan gum aqueous solution into a beaker and add NaIO dropwise 4 Aqueous solution (xanthan gum and NaIO 4 The molar ratio is 1:1); after that, the mixture was stirred for 2h in the dark; then 1ml of ethylene glycol was added to neutralize the unreacted NaIO 4 , the reaction was stirred for another 1 h, and the solution was purified with distilled water using a dialysis bag for 2 days, and the water was renewed 8 times a day during the dialysis; finally, the Xan-CHO product was freeze-dried in a freeze dryer, and then sealed at 4 °C Store in a plastic bag.

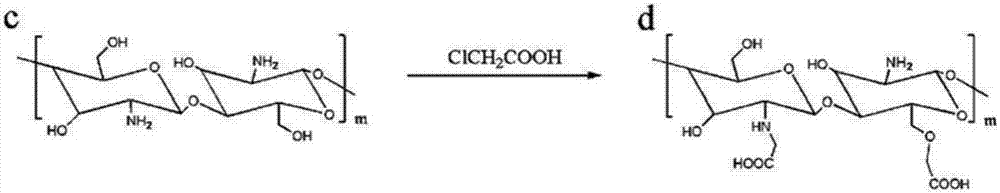

[0060] 2. Synthesis of carboxymethyl chitosan: Suspend 10g of chitosan in 50ml of isopropanol, then stir at room temperature, divide 20ml of 5mol / L NaOH aqueous solution into 5 parts, and add them to the stirring solution at intervals of 5min After that, the resulting s...

Embodiment 3

[0064] 1, the synthesis of aldehydated xanthan gum: prepare 2% (w / v) xanthan gum aqueous solution and 20% (w / v) NaIO 4 aqueous solution, then pour the xanthan gum aqueous solution into a beaker and add NaIO dropwise 4 Aqueous solution (xanthan gum and NaIO 4 The molar ratio is 1:3); Afterwards, the mixture was stirred for 4h in a dark room; Then 3ml of ethylene glycol was added to neutralize unreacted NaIO 4 , the reaction was stirred for another 2 h, and the solution was purified with distilled water using a dialysis bag for 4 days, and the water was renewed 5 times a day during the dialysis; finally, the Xan-CHO product was freeze-dried in a freeze dryer, and then sealed at 4 °C Store in a plastic bag.

[0065] 2. Synthesis of carboxymethyl chitosan: Suspend 20g of chitosan in 100ml of isopropanol, then stir at room temperature, divide 40ml of 15mol / L NaOH aqueous solution into 5 parts, and add them to the stirring solution at intervals of 5min After that, the resulting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com