Biodegradable adhesive as well as preparation method and application thereof

A biodegradable and adhesive technology, applied in the direction of adhesives, etc., can solve the problems such as the relative molecular weight biodegradation rate of polyester adhesives, high cost, rare adhesives and other problems that are not specified clearly, to avoid excessive volatile harmful gases, high efficiency, The effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

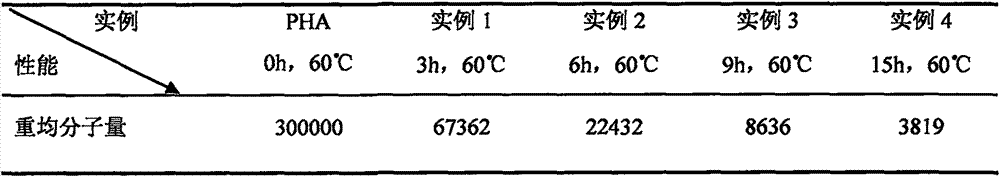

[0024] (1) PHA lye chemical degradation product preparation in the embodiment

[0025] Add NaOH solution to the four reactors respectively, and then add PHA powder in the proportion of 5% of the mass of the alkali solution, control the temperature at 60° C., and the stirring speed at 150 r / min. The reactants were taken out at 3h, 6h, 9h, and 15h respectively, and dried in an oven.

[0026] (2) PHA lye chemical degradation product performance characterization in the embodiment

[0027] ① Fourier infrared spectroscopy test

[0028] KBr powder is mixed, ground and pressed into thin slices, with a scanning range of 400cm -1 ~4000cm -1 , resolution 4cm -1 , scan frequency 32. PHA alkaline chemical degradation products at 3400cm -1 A significantly increased absorption peak (the characteristic-OH peak of the alkali chemical degradation product of PHA) appears at , while the PHA before degradation is at 3400cm -1 The small absorption peak indicates that PHA undergoes alkaline c...

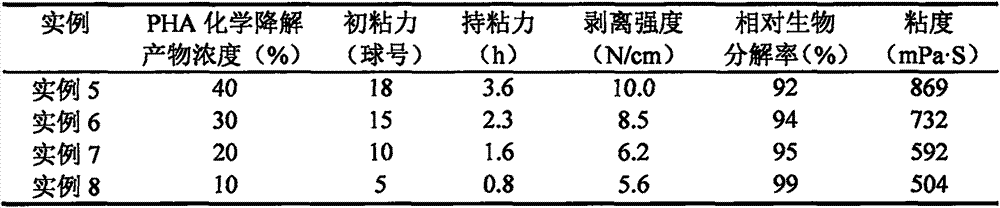

example 5~8

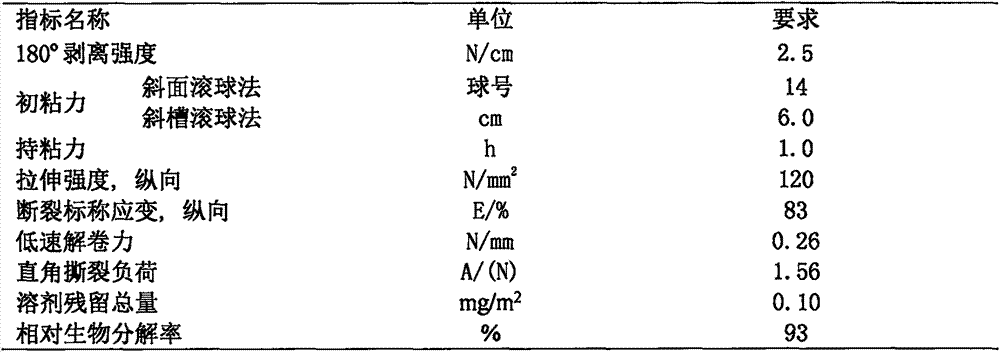

[0034] Dilute the PHA alkali chemical degradation product obtained in Example 4 with distilled water to control the pH value of the final solution at 6-9 to obtain a biodegradable adhesive. According to the solid content of the solution, take a quantitative solution and apply it evenly on the kraft paper with a scraper, put it in an oven and dry it for 10 minutes to obtain a glue content of 12mg / cm 2 pressure sensitive tape. Among them, the initial adhesion test adopts the inclined surface rolling ball method in the national standard GB / T4852-2002 (inclination angle of 30°, the length of the sample is more than 250mm, and the width is 10-80mm), and the maximum size of the steel ball that can be adhered to the viscous surface of the specified length is detected. The holding force test adopts the test method of the adhesive tape to the standard test steel plate in the national standard GB / T4851-2014 (the length of the sample is 150mm, and the width is 12±0.5mm), and the adhesive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com