Long-afterglow light conversion agent and preparation method thereof, and long-afterglow light conversion film and preparation method thereof

A long afterglow and light-changing agent technology, which is applied in the fields of botany equipment and methods, chemical instruments and methods, luminescent materials, etc., can solve the problems of prolonging the afterglow time, and achieve the effect of promoting and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

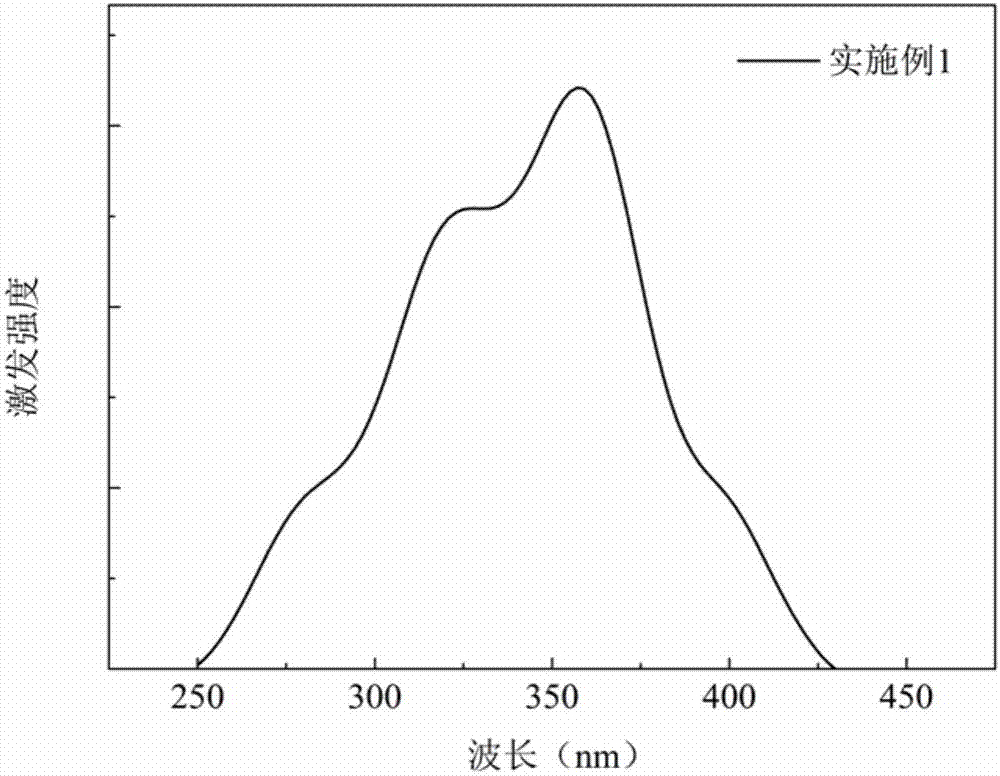

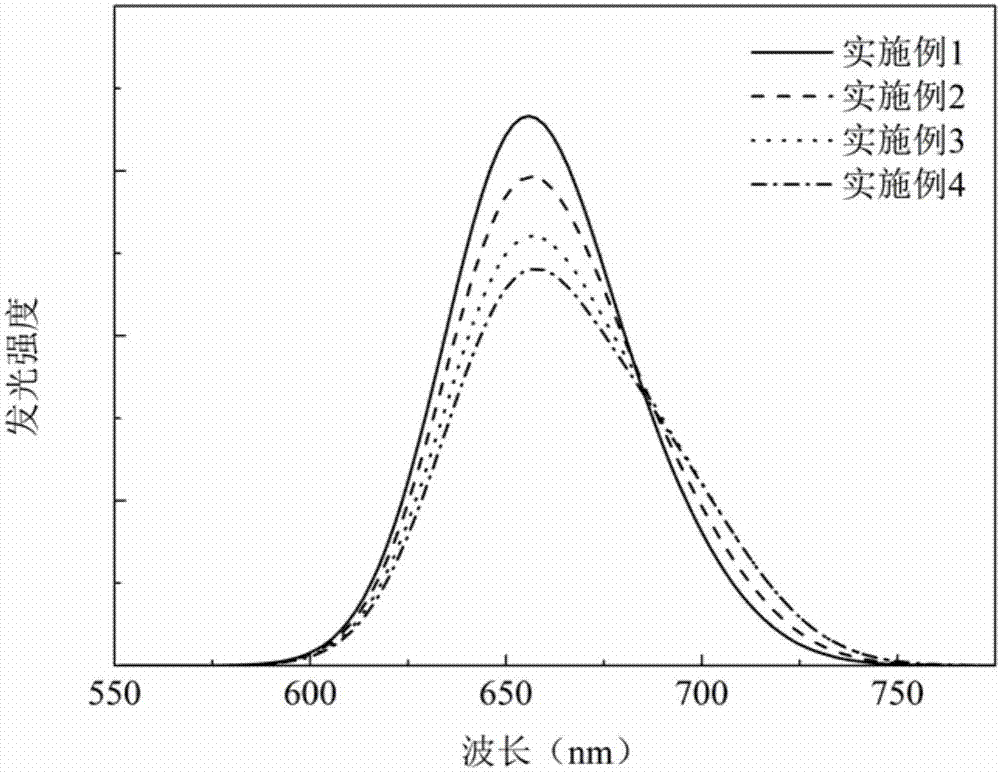

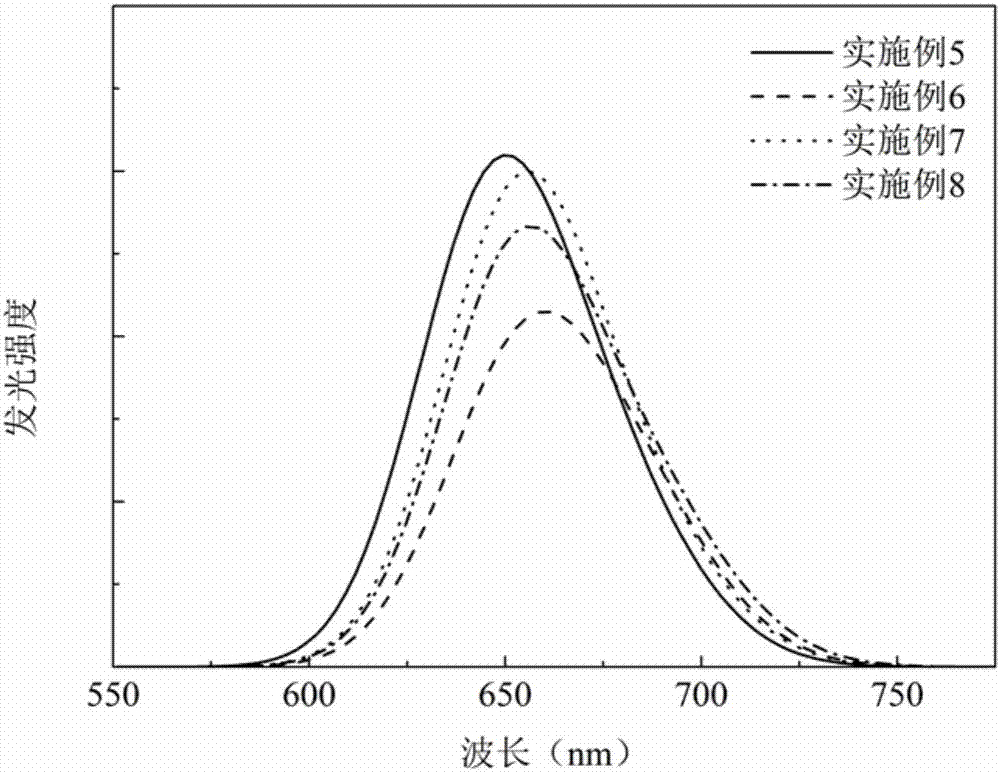

[0022] Preparation of long afterglow light conversion agent: using high-purity SrCO 3 、Al 2 o 3 , AlN, Eu 2 o 3 and Dy 2 o 3 As raw material, according to the chemical formula SrAl 2 o 3 N 2 / 3 :0.02Eu 2+ ,0.02Dy 3+ The stoichiometric ratio of each raw material is weighed; then the obtained raw materials are fully ground in an agate mortar and mixed evenly, and the obtained mixture is put into a corundum crucible, and then the corundum crucible and the mixture are put into a high temperature tube furnace Burning, the burning temperature is 1300°C, the burning time is 10 hours, and the sintering atmosphere is a mixture of 5% hydrogen and 95% nitrogen. After the burning is completed, the sample is cooled to room temperature with the furnace, and finally the sintered body is taken out for further processing. The long-lasting light-changing agent can be obtained by ball milling, pulverizing, washing and drying.

[0023] Light conversion film blowing: (1) Weigh 80 parts o...

Embodiment 2

[0031] Preparation of long afterglow light conversion agent: using high-purity SrCO 3 、Al 2 o 3 , AlN, Eu 2 o 3 and Nd 2 o 3 As raw material, according to the chemical formula SrAl 2 o 5 / 2 N:0.03Eu 2+ , 0.03Nd 3+ The stoichiometric ratio of each raw material is weighed; then the obtained raw materials are fully ground in an agate mortar and mixed evenly, and the obtained mixture is put into a corundum crucible, and then the corundum crucible and the mixture are put into a high temperature tube furnace Burning, the burning temperature is 1350°C, the burning time is 9 hours, and the sintering atmosphere is a mixture of 5% hydrogen and 95% nitrogen. After the burning is completed, the sample is cooled to room temperature with the furnace, and finally the sintered body is taken out for further processing. The long-lasting light-changing agent can be obtained by ball milling, pulverizing, washing and drying.

[0032] Light conversion film blowing: (1) Weigh 50 parts of po...

Embodiment 3

[0034] Preparation of long afterglow light conversion agent: using high-purity SrCO 3 、Al 2 o 3 , AlN, Eu 2 o 3 and La 2 o 3 As raw material, according to the chemical formula SrAl 2 o 2 N 4 / 3 :0.02Eu 2+ , 0.02La 3+ The stoichiometric ratio of each raw material is weighed; then the obtained raw materials are fully ground in an agate mortar and mixed evenly, and the obtained mixture is put into a corundum crucible, and then the corundum crucible and the mixture are put into a high temperature tube furnace Burning, the burning temperature is 1400°C, the burning time is 8 hours, and the sintering atmosphere is a mixture of 5% hydrogen and 95% nitrogen. After the burning is completed, the sample is cooled to room temperature with the furnace, and finally the sintered body is taken out for further processing. The long-lasting light-changing agent can be obtained by ball milling, pulverizing, washing and drying.

[0035] Light conversion film blowing: (1) Weigh 75 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com