Novel anaerobic fermentation tank and up-flow full-mixing type anaerobic fermentation system

An anaerobic fermentation tank, a new type of technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical equipment, etc., can solve the problems of easy stratification, difficult maintenance, and poor fluid stirring effect To achieve the effect of ensuring the fermentation temperature, convenient construction and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

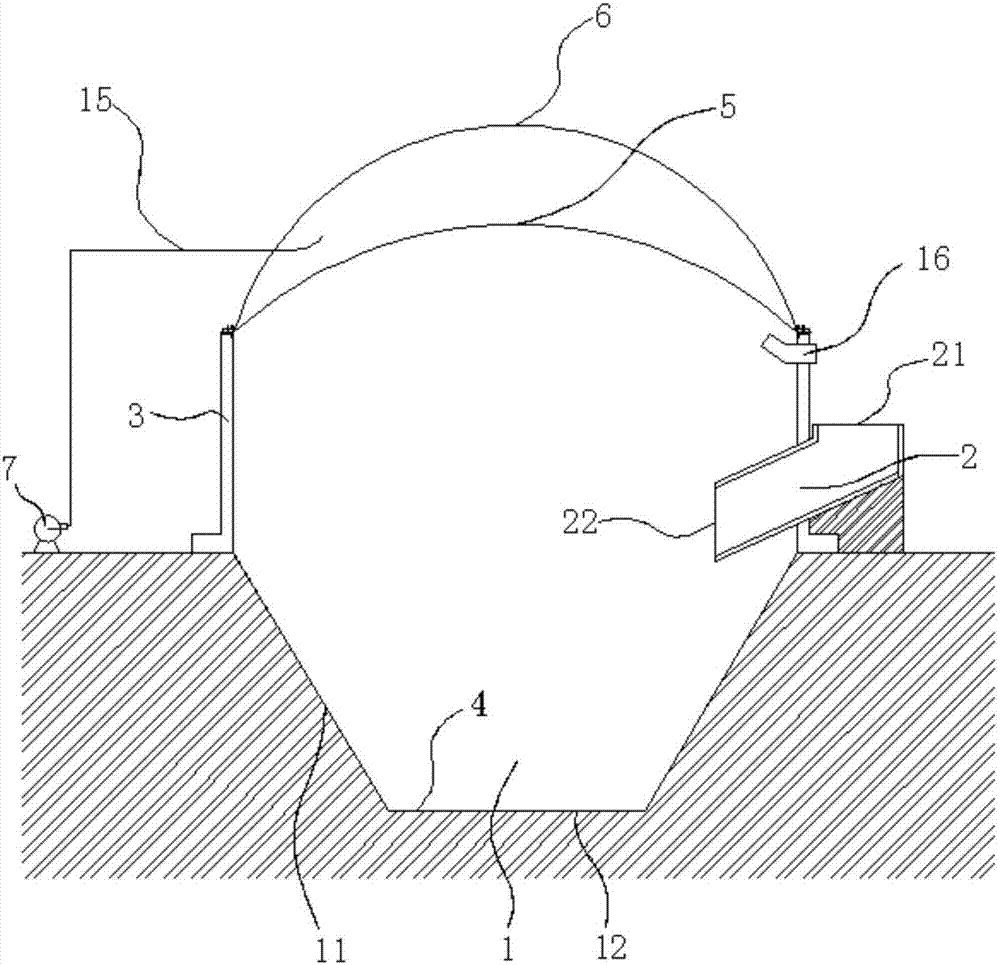

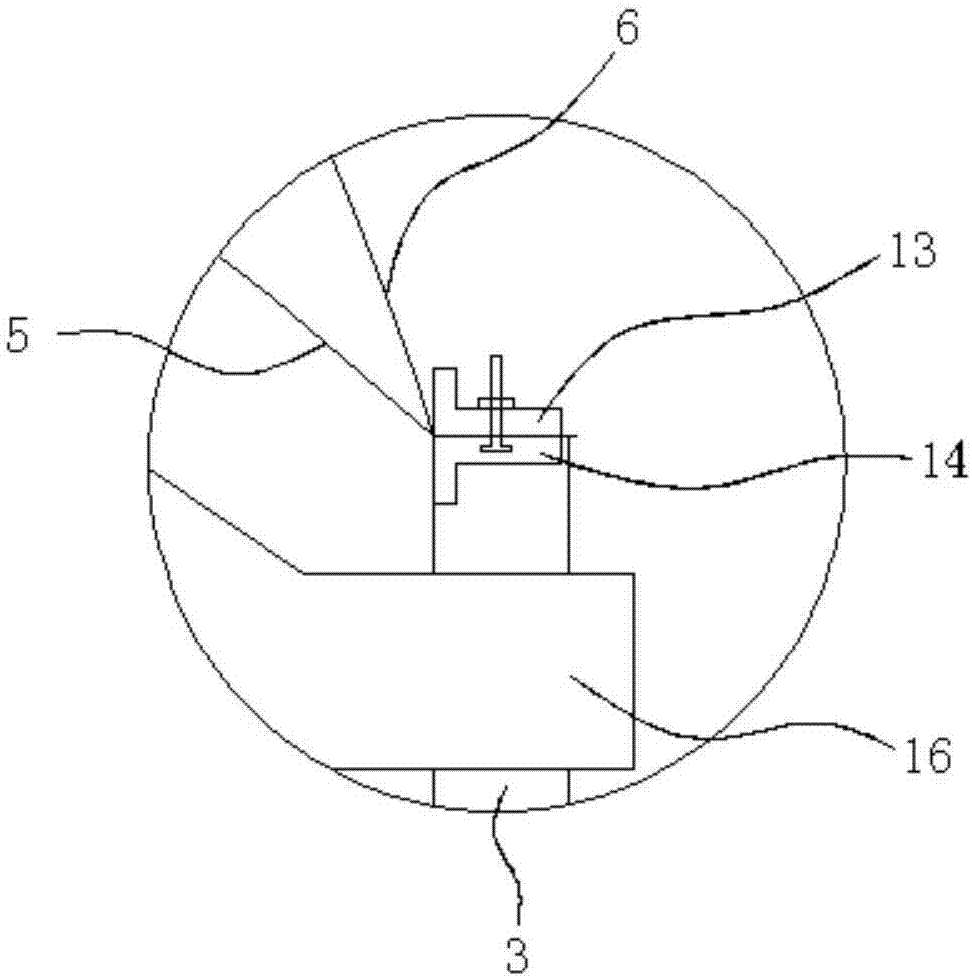

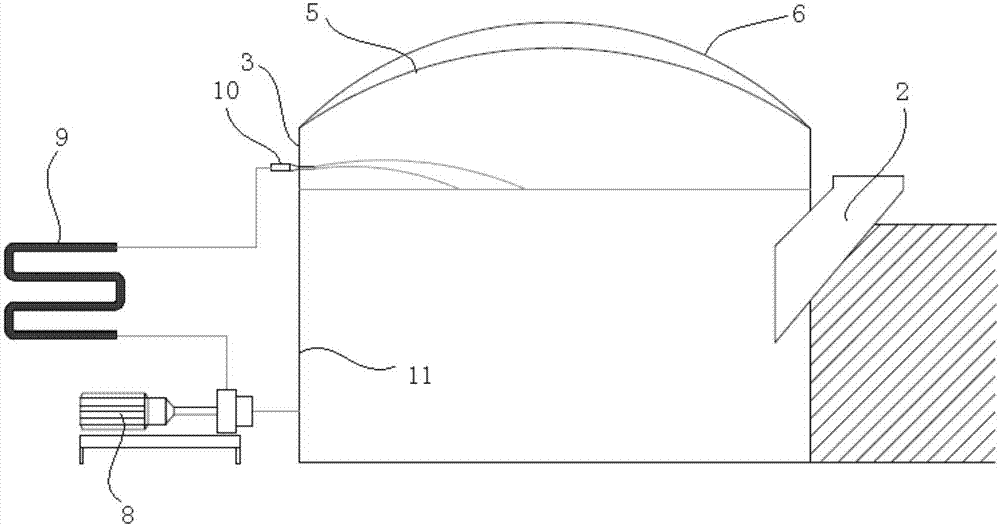

[0025] like figure 1 As shown, the embodiment of the present invention provides a novel anaerobic fermenter, which includes a base tank 1 dug out of the ground, a feed bin 2 communicated with the base tank 1, and the ground around the base tank 1 The shape of the upper tank wall 3 and the base tank 1 can be rectangular, and it is preferable to set the base tank 1 as an inverted conical or cylindrical shape. The base pool 1 includes a side wall 11 and a pool bottom 12. After the base pool 1 is dug out, the side wall 11 and the pool bottom 12 are compacted, and then a multi-layer waterpro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com